Schutzgase für Atmosphärenöfen: Wasserstoff vs. Stickstoff vs. Argon

Mit über 20 Jahren Erfahrung in industriellen Hochtemperaturanwendungen weiß ich, welche entscheidende Rolle Schutzgase spielen...

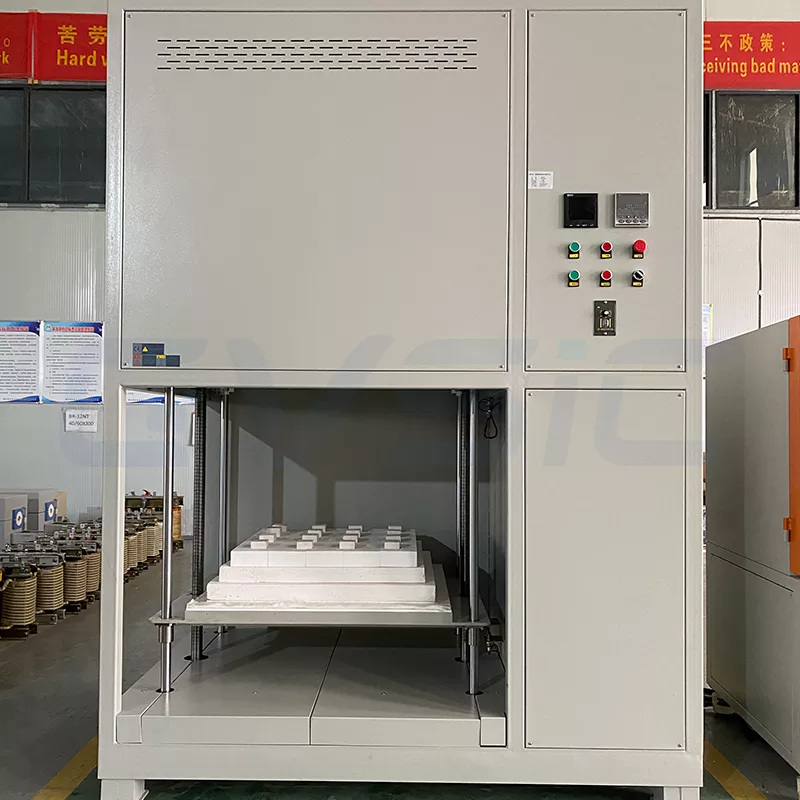

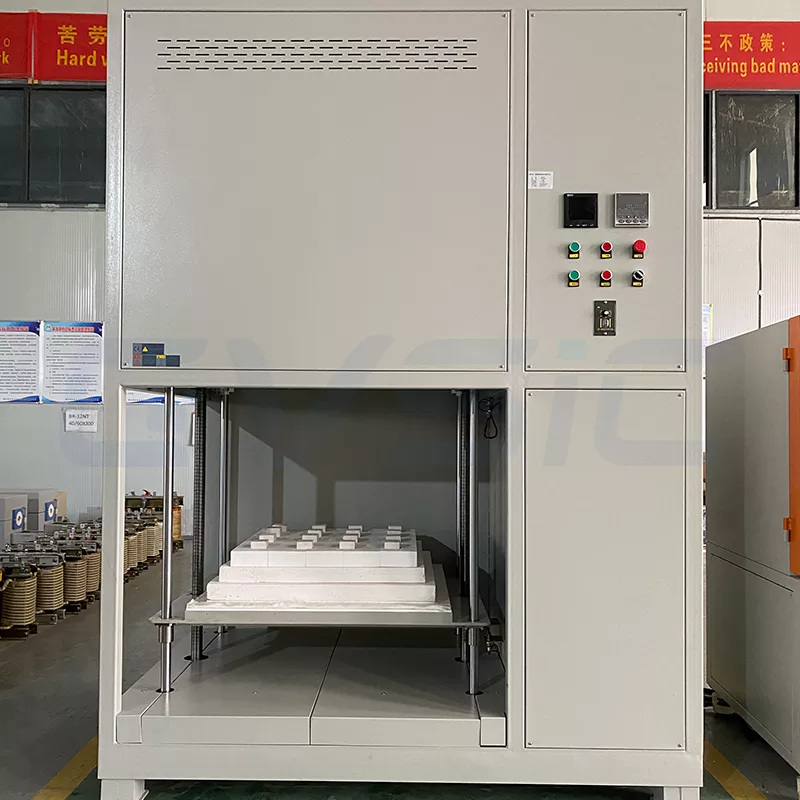

Der CVSIC Retort Atmosphärenofen wurde für das präzise Sintern von Keramik und Pulvern entwickelt und erreicht 1000°C mit PID-Steuerung, Heißwandheizung und Unterstützung für inerte/oxidierende Atmosphären. Ideal für Forschung, Tests und die Produktion in kleinem Maßstab. Individuelle Anpassung möglich. Kontaktieren Sie uns für Details.

Der CVSIC Retort Atmosphärenofen ist ein hocheffizientes thermisches Verarbeitungssystem, das für präzises Sintern, Glühen und Wärmebehandlung unter kontrollierten atmosphärischen Bedingungen entwickelt wurde. Unter Verwendung eines Warmwand-Außenheizung DesignEr trennt die Heizelemente von der Ofenkammer, was die Lebensdauer der Komponenten erheblich verlängert und das Risiko einer Verunreinigung verringert.

Es unterstützt inert (N₂, CO₂, Ar) und oxidierende Atmosphären (Luft, Sauerstoff) mit einem Vakuumniveau von bis zu 7×10-³ PaDadurch eignet es sich für eine breite Palette von Prozessen mit hochreinen Materialien, darunter keramik, Pulvermetallurgie, elektronische Materialien, und Forschung über seltene Erden. Das System kombiniert PID-Temperaturregelung, modulare Atmosphärensteuerung, und Mehrschichtiger SicherheitsschutzDas macht ihn zu einer zuverlässigen Wahl für Labore, F&E-Zentren und Produktionsumgebungen.

Externe Warmwasser-Wandheizung: Die Heizelemente befinden sich außerhalb der Ofenkammer, wodurch ein direkter Materialkontakt vermieden und die Lebensdauer der Komponenten sowie die thermische Stabilität verbessert werden.

Hohe Temperatur & Präzisionskontrolle: Maximale Temperatur von 1000°C; Betriebstemperatur bis zu 950°C. Der PID-Regler gewährleistet eine Genauigkeit von ±1°C (±2°C während der Gasbefüllung), mit einer Gleichmäßigkeit von ±5°C über die gesamte Arbeitszone.

Vielseitige Atmosphärenunterstützung: Kompatibel mit N₂, Ar, CO₂, Sauerstoff und Luft; anpassbare Gaseinlässe und Durchflusskontrolle (Schwimmer/Protonen-Durchflussmesser). Vakuum im kalten Zustand bis zu 7×10-³ Pa.

Robuste Ofenkammer: Hitzebeständige Stahlstruktur mit korrosionsbeständiger Isolierung, die Stabilität bei wiederholten Temperaturwechseln gewährleistet.

Fortschrittliches Sicherheitssystem: Zu den Merkmalen gehören Übertemperaturalarme, Gasschutzverriegelungen, eine explosionssichere Konstruktion und multimodale Gasemissionen, die einen sicheren Betrieb und die Einhaltung von Umweltvorschriften gewährleisten.

Energieeffizient: Optimierte Wärmedämmung und Struktur reduzieren den Wärmeverlust und verbessern die Energieeffizienz bei längeren Zyklen.

Benutzerfreundliche Steuerung: Manuelle und automatische Betriebsmodi werden unterstützt, mit Heizraten von bis zu 10°C/min, was eine flexible Prozessabstimmung ermöglicht.

Um den unterschiedlichen industriellen und akademischen Anforderungen gerecht zu werden, bietet CVSIC umfassende Anpassungsmöglichkeiten:

Anmerkung: Spezifikationen können angepasst werden. Kontaktieren Sie uns, um Ihre spezifischen Prozessanforderungen zu besprechen.

Ganz gleich, ob Sie fortschrittliche Keramik entwickeln oder modernste Materialforschung betreiben, der Retortenofen von CVSIC bietet Präzision, Stabilität und eine individuelle Anpassung an Ihre Bedürfnisse.

Wenden Sie sich noch heute an unser technisches Team, um eine Beratung, einen Preis oder eine maßgeschneiderte Lösung zu erhalten.

Wenden Sie sich noch heute an CVSIC, wenn Sie eine Lösung für das Entheizen aus einer Hand benötigen! Mit mehr als fünfzehn Jahren Erfahrung in Forschung und Entwicklung sowie in der Herstellung haben wir absolutes Vertrauen in unsere Produkte! Nehmen Sie Kontakt mit uns auf, um kostenlose Muster zu erhalten!

Mit über 20 Jahren Erfahrung in industriellen Hochtemperaturanwendungen weiß ich, welche entscheidende Rolle Schutzgase spielen...

Da ich viele Jahre in der Hochtemperaturindustrie gearbeitet habe, weiß ich genau, wie wichtig die Pulvermetallurgie (PM)...

Vakuum- vs. Atmosphären-Röhrenöfen: Die Auswahl der optimalen Ausrüstung für Ihre Experimente Probenoxidation oder Kontamination bei Hochtemperaturen...

Kontaktieren Sie CVSIC noch heute für exklusive Heizlösungen. Kostenlose Muster und technische Unterstützung!

CE, SGS, ISO-Zertifikat

15+ Jahre Fabrik

Gebrauchsanweisung

7*24-Stunden-Kundenservice