Introduction: Temperature and Materials—The Fundamental Principles of Sintering Furnaces

The creation of high-quality restorations is significantly influenced by temperature regulation and material compatibility in dental sintering furnaces. Whether it’s the durability of all-ceramic crowns or the clarity of zirconia, the temperature settings of the furnace and the appropriate materials play a crucial role in determining the final results.

CVSIC offers an in-depth examination of typical temperature ranges for dental sintering furnaces along with their related materials. This guide helps you select and use equipment efficiently, ensuring you provide patients with perfect smiles.

Common Temperature Ranges for Dental Sintering Furnaces

Dental sintering furnaces are mainly designed for high-temperature sintering applications, usually functioning within a range of 1400°C to 1600°C. The exact temperature ranges vary depending on the material being processed and the specific technique used. Below are typical temperature ranges along with their features:

Standard Sintering Temperature (1450°C – 1550°C)

- Application: Regular sintering for the majority of zirconia materials.

- Features: Suitable for standard zirconia types (e.g., high-strength or high-translucency zirconia). Provides a good balance of strength and aesthetics, making it perfect for all-ceramic crowns, bridges, and similar uses.

- The sintering cycle generally spans 6-8 hours, which includes phases of heating, holding, and gradual cooling.

- CVSIC Highlight: Our zirconia sintering furnacesupports precise temperature control (±1°C), guarantees stable and effective standard sintering operations.

Rapid Sintering Temperature (1500°C – 1600°C)

- Application: Speedy sintering process suited for high-translucency zirconia or urgent small-batch orders.

- Features: Cuts down the sintering duration to 3-4 hours, making it ideal for high-efficiency laboratories.

- Requires elevated temperatures to hasten crystal structure formation, necessitating more precise temperature control of the equipment.

- Compatible with certain brands of high-translucency zirconia materials.

CVSIC Recommendation: Our rapid sintering mode is tailored for time-sensitive orders, striking a balance between efficiency and quality with yields reaching up to 99%.

Low-Temperature Sintering (1350°C – 1450°C)

- Application: Designed for certain low-melting-point zirconia or mixed materials.

- Features: Utilized for specific new zirconia compositions, minimizing energy consumption and thermal stress.

- Extended sintering time (8-10 hours) ensures stability of material properties.

- Ideal for small clinics or low-volume production scenarios.

CVSIC Advantage: Our sintering furnaces accommodate flexible temperature profiles suitable for a variety of zirconia materials.

Tip: Suggested sintering temperatures may differ slightly between zirconia brands (e.g., 3M, VITA, Ivoclar). When selecting a sintering furnace, ensure that the device supports multi-stage programmed heating to accommodate a range of materials.

Common Materials for Dental Sintering Furnaces

Dental sintering furnaces mainly process zirconia but are also capable of handling other materials with high melting points. Below are typical materials along with their compatibility with sintering furnaces:

Zirconia (ZrO₂)

Characteristics: Exhibits high strength (900-1200 MPa), making it suitable for all-ceramic crowns, bridges, and implant abutments. Offers high translucency (particularly high-translucency or ultra-translucent zirconia), providing excellent aesthetic outcomes.

Demonstrates good biocompatibility, making it widely utilized in contemporary dental restorations.

Sintering Temperature: Ranges from 1450°C to 1600°C (varies with brand and model).

Process Requirements: Needs a slow heating and cooling rate (approximately 2-3°C/min) to avoid thermal stress cracking. Employ dedicated sintering discs and support beads to ensure uniform heating of restorations.

CVSIC Recommendation: Our zirconia sintering- furnace equipped with an intelligent temperature control system is an ideal match for all zirconia materials.

High-Melting-Point Metal Alloys

Characteristics: Utilized for metal-ceramic crowns or hybrid restorations, providing high strength albeit with somewhat reduced aesthetics. Commonly includes cobalt-chromium alloys, nickel-chromium alloys, and similar materials.

Sintering Temperature: Between 1300°C and 1500°C (depends on the type of alloy).

Process Requirements: Requires consistent heating to avoid thermal deformation. Some alloys necessitate sintering in protective atmospheres (e.g., argon).

CVSIC Recommendation: Our adaptable sintering furnaces can process metal alloy materials and fulfill the requirements for hybrid substances.

Other Emerging Materials

Characteristics: Comprises certain low-temperature sintered zirconia or composites that are suitable for specific restorative needs. Advances in dental materials highlight the need for greater flexibility in furnaces for newer materials.

Sintering Temperature: Ranges from 1350°C to 1450°C.

Process Requirements: Supports customized sintering profiles to cater to new materials.

CVSIC Highlight: Our sintering furnace is capable of accommodating over 100 customizable programs, effectively managing new materials.

Considerations for Temperature and Material Compatibility

Adhere to Manufacturer Guidelines

Various zirconia brands (such as 3M and VITA) have different requirements regarding sintering temperature and duration. Thoroughly examine the material specifications before usage and choose a sintering furnace with adjustable program settings.

Minimize Temperature Variations

Significant temperature fluctuations may lead to an inconsistent zirconia crystal structure, which can weaken strength and translucency. CVSIC furnaces employ PID temperature control technology to keep variations within ±1°C.

Choose Suitable Sintering Pans

Utilize high-quality sintering pans and support beads (for instance, zirconia beads) to guarantee even heating of restorations, avoiding deformation or contamination.Be Aware of Rapid Sintering Risks

While rapid sintering improves efficiency, it requires stricter adherence to material and equipment guidelines, which may affect restoration performance. CVSIC’s optimized rapid sintering mode effectively balances efficiency with quality.

How to Choose the Right Sintering Furnace?

When selecting a dental sintering furnace, key factors to consider include the temperature range and material compatibility. Here are some practical suggestions:

Determine Material Specifications: For primary zirconia processing, CVSIC’s furnaces are designed explicitly for zirconia.

Emphasize Precision in Temperature Control: Select models that offer accuracy within ±1°C to ensure the quality of restorations.

Match with Production Needs:

- Small clinics: Choose compact models (1-2 sintering trays).

- Large laboratories: Opt for high-throughput models (3-5 sintering trays).

Think About Energy Usage and Maintenance

- Select energy-efficient models to reduce CVSIC’s long-term operational expenses.

- Favor brands that provide after-sales support, like CVSIC’s 24/7 technical assistance.

Need extra purchasing guidance? Visit our zirconia sintering furnace buying guide!

Practical suggestions for the use and upkeep of sintering furnaces

Appropriate usage and consistent maintenance prolong the lifespan of the furnace and guarantee the quality of restorations.

Usage Advice:

- Clean the furnace chamber before operating to avoid zirconia contamination from dust or debris.

- Choose the recommended sintering curves specific to the material brand to prevent cracking caused by excessively rapid heating rates.

- Utilize dedicated sintering discs and support beads for consistent heating of restorations.

Maintenance Suggestions

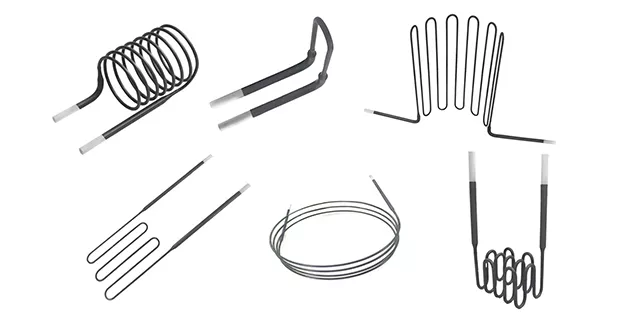

- Regularly check the wear on silicon carbide rods; replace all rods every 12-18 months.

- Remove residual debris from the furnace chamber to prevent negatively affecting the quality of future sintering.

- Periodically recalibrate temperature sensors to ensure accurate temperature regulation.

Want to discover more maintenance suggestions? Visit our Dental Furnace Maintenance Guide

Why Opt for CVSIC Sintering Furnaces?

At CVSIC, we recognize the crucial role zirconia sintering plays in dental laboratories. Our furnaces have gained industry confidence through outstanding performance and committed service:

- Accurate Temperature Regulation: ±1°C variation guarantees that restorations achieve maximum strength and visual appeal.

- Versatile Programming: Accommodates over 100 custom sintering curves that are compatible with various zirconia brands.

- Range of Options: From compact units to high-capacity models to meet diverse scale needs.

- Worldwide Support: 24/7 technical assistance, OTA firmware updates, and prolonged equipment longevity.

Explore CVSIC’s Dental Furnace today and discover the ideal sintering furnace for your laboratory!

FAQ

What is the standard temperature range for zirconia sintering furnaces?

Typically, it ranges from 1400°C to 1600°C. Normal sintering temperatures should be maintained between 1450°C and 1550°C, while rapid sintering may reach up to 1600°C, depending on CVSIC’s material.

Can sintering furnaces handle ceramic materials?

Sintering furnaces are mainly intended for zirconia processing. Porcelain furnaces are usually required for ceramic materials. However, CVSIC’s multi-functional furnace can accommodate both applications.

Does rapid sintering affect the quality of zirconia?

If equipment and procedures are properly optimized, rapid sintering can strike a balance between efficiency and quality. CVSIC’s rapid sintering mode is rigorously tested to ensure the production of high-quality finished products.

How can I choose the appropriate sintering furnace for zirconia?

Focus on furnaces that provide precise temperature control (±1°C), multi-step programming, and capacity suitable for your production level. For more information, refer to our zirconia sintering furnace buying guide.

Which zirconia brands can be used with CVSIC sintering furnaces?

Our furnaces are compatible with leading brands (such as 3M, VITA, Ivoclar) and permit custom programming to meet specific material needs.

Conclusion

The temperature range and material compatibility in dental sintering furnaces are vital factors that influence both restoration quality and workflow efficiency. CVSIC is dedicated to offering high-performance, versatile sintering furnace solutions to assist your lab in producing perfect zirconia restorations. Interested in learning more? Visit our dental furnace products today!