“We’ve been working with this supplier for over two years for our industrial glass furnaces. Their silicon carbide heating elements are extremely durable and cost-effective. Highly recommend for any high-temperature application.”

CVSIC is China’s leading manufacturer and supplier of electric heating elements(SiC & MoSi2). We provide reliable heating solutions for labs and industries worldwide.

Who we are?

Dengfeng Chuangwei Carbide Products Co., LTD.

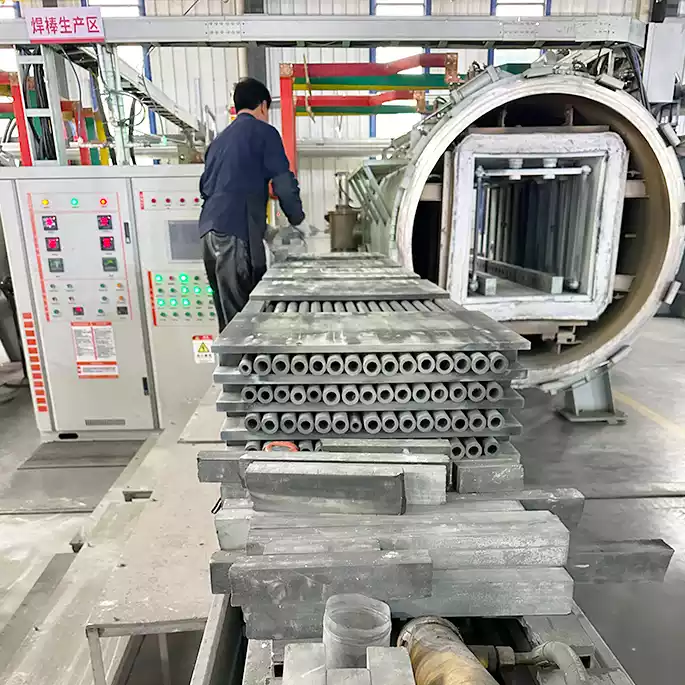

CVSIC, founded in 2014, is located in Dengfeng City, China, with a factory spanning 13,000 square meters and employing over 130 skilled staff members. Our products include silicon carbide heating elements, molybdenum disilicide heating elements, tungsten-molybdenum products, and industrial kilns, providing customized heating solutions for global industries.

Our other services:

Experience

exporting countries

Cooperating Partners

CVSIC boasts extensive experience, robust production and R&D capabilities, with products meeting international standards.

International Quality Certification: CVSIC is ISO quality management system certified and holds full export qualifications, ensuring every products international standards.

In-House Factory with Strict Quality Control: From raw materials to finished products, we manage the entire production process to ensure consistency and high reliability.

Experienced Core Team: Our engineering team has years of expertise in silicon carbide materials, with the ability to address complex heating requirements.

Highly Efficient and Durable SiC Heating Elements: Made from premium silicon carbide materials, offering excellent thermal conductivity, oxidation resistance, and long service life.

Continuous Innovation: Staying at the forefront of the industry, we continuously optimize product structure and performance to meet diverse needs in high-temperature and high-precision applications.

Customized Solutions: Tailored heating solutions designed to meet specific voltage, power, and size requirements.

Fast Delivery: Standardized processes and flexible production ensure quick order response and on-time delivery.

Professional After-Sales Support: Comprehensive services including technical consultation, installation guidance, and troubleshooting for worry-free customer experience.

Industry Solutions: Reliable heating systems for research labs, industrial kilns, heat treatment equipment, and new energy material applications.

Kiln-Specific Heating Elements: Designed for various atmospheres and temperature conditions, ensuring stability in continuous high-temperature operations.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Signs of Uneven Heating and Slow Temperature Rise In lab or industrial settings, muffle furnace users often faceSigns of Uneven Heating and Slow Temperature Rise In lab or industrial settings, muffle furnace users often face these telltale issues: These symptoms typically indicate a disrupted internal thermal field or control system drift. Today, CVSIC shares proven causes and fixes for uneven muffle furnace heating, empowering you to diagnose and resolve issues swiftly for…

For many procurement engineers, “How to pick a ceramic fiber board?” seems like a straightforward question, but whenFor many procurement engineers, "How to pick a ceramic fiber board?" seems like a straightforward question, but when it hits your project, you'll spot: I've seen plenty of on-site disasters from bad ceramic fiber board choices: furnace walls falling off, uneven electric furnace heating, energy costs shooting up, insulation layers caving in... Almost always 'cause…

Routine maintenance and cleaning are vital for ensuring the longevity of your muffle furnace and the success ofRoutine maintenance and cleaning are vital for ensuring the longevity of your muffle furnace and the success of your experiments. Whether your furnace uses resistance wire, SiC, or MoSi2 heating elements, neglecting upkeep can result in unstable temperatures, component damage, or even failed trials. In this guide, CVSIC outlines practical tips for daily maintenance and…

Ceramic fiber materials aren’t “new materials” anymore; they’ve become the go-to lightweight refractory materials in industries like metallurgy,Ceramic fiber materials aren't "new materials" anymore; they've become the go-to lightweight refractory materials in industries like metallurgy, heat treatment, kilns, electric furnaces, glass, and petrochemicals. But for many engineering firms, buyers, and even some tech folks, questions like "how do I pick the right ceramic fiber board, which type fits my furnace, where do…

We supply a full range of high-temperature heating products including:

Our products are widely applied in:

Laboratory heat treatment and materials analysis

Industrial kilns and powder metallurgy

Ceramic sintering and metal annealing

Dental prosthesis processing and debinding

High-temperature insulation and furnace lining systems

Yes. We provide full customization services, including:

Custom size, power, and temperature range

Furnace structure, control system, and atmosphere interface customization

Private labeling (OEM / ODM) and packaging design support

Founded in 2014, we have decades of expertise in high-temperature engineering, with:

Modern production facilities and automated lines

ISO9001-certified quality system

Advanced resistance and temperature testing equipment

A professional R&D team for non-standard design and new material development

All products go through strict raw material inspection, sintering control, electrical testing, and final quality inspection.

Each product has its own test record and tracking number to guarantee stability and reliability.

No, most standard models have no MOQ (MOQ = 1 unit).

We welcome trial orders and small-quantity tests before bulk purchases.

Standard products: 7–10 days

Customized products: 15–30 days

We also support urgent production and global air or sea shipping.

We provide flexible international shipping options based on order size and customer preference:

We always discuss and confirm the best shipping method with each client before shipment to ensure cost efficiency and timely delivery.

Our products are exported to over 50 countries worldwide, including Europe, America, Asia, the Middle East, and Africa.

We support EXW, FOB, CIF, and DDP trade terms according to customer requirements.

As heating elements are consumable items, the warranty policy is as follows:

Yes. Our experienced engineers offer:

Yes. We provide free samples for certain models, and customers only need to cover the shipping cost.

It’s the best way to test performance and compatibility before mass purchasing.

Email: [email protected]

Website: https://cvsicelement.com/

Phone / WhatsApp: +86 15936296688

We reply to all inquiries within 24 hours.

Absolutely. We welcome global distributors and partners to expand local markets together.

We provide distributor pricing, technical training, and marketing support.

Please let us know your requirements and contact details and we will get back to you within 8 hours!