The 1100°C muffle furnace is an essential tool for laboratories and the light industry, excelling at material pretreatment, ash determination, and necessary heat treatments.

A frequent buyer question: “What can 1100°C process—is it hot enough?” As an engineer, I’ll answer with practical insights.

The Value of the 1100°C Temperature Range

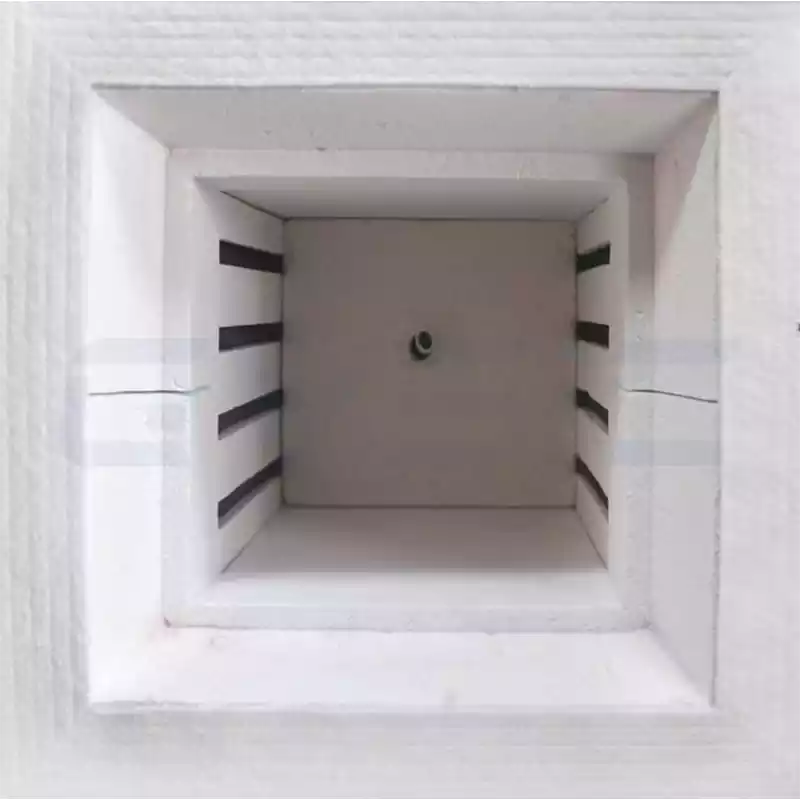

At 1100°C, the chamber provides uniform, sustained heat at this level.

Resistance wire elements (nickel-chromium or iron-chromium alloys) provide steady, reliable, and low-maintenance heating, suitable for continuous lab work.

While 1100°C won’t sinter high-melting ceramics or oxides, it’s cost-effective for most lab and industry tasks.

Based on extensive experience and feedback, here is a concise summary of the experiments and materials ideally matched to the 1100°C muffle furnace.

Key Experiments for 1100°C Muffle Furnaces

These furnaces shine in labs for their versatility. Here are the top applications:

Ashing Experiments

Staple in chemical analysis, ashing quantifies organics or volatiles in soil, food, or polymers. At 1100°C, it combusts organics, preserving inorganic residues.

CVSIC’s 1100°C and 1200°C muffle furnaces ensure consistent results and feature easy-to-clean chambers that reduce cross-contamination. One client cut the ashing cycle time by 15% through process tweaks.

Drying and Moisture Removal

It strips water or solvents from samples like reagents or minerals. It quickly reaches a few hundred degrees, protecting sample integrity.

I recommend CVSIC’s 1200°C small Muffle Furnaces—each offers a small footprint ideal for routine lab drying without taking up valuable bench space.

Low-Temperature Annealing

Annealing refines crystal structures or relieves stress in metals like copper or aluminium, or low-melting alloys. Though not extreme, 1100°C softens materials effectively, boosting ductility.

For example, I directed a materials lab to our 1100°C and 1200°C muffle furnaces for copper annealing. They saw significant performance and run-to-run consistency gains.

Thermal Decomposition and Pyrolysis

Many compounds break down below 1100°C, aiding reaction studies or new material synthesis. Take carbonate decomposition (CaCO₃ → CaO + CO₂), which typically runs at 800–1000°C—our furnaces handle it effortlessly.

Materials Ideal for 1100°C Muffle Furnaces

This temperature sweet spot suits a broad array of materials:

Organic Materials and Samples

- Soil, Plants, Food: Ideal for ashing to isolate inorganics. 1100°C incinerates organics cleanly without harming heat-resistant residues.

- Polymers and Plastics: Probe filler levels or thermal stability; it decomposes most polymer matrices reliably.

Low-Melting-Point Metals and Alloys

- Copper, Aluminium, Zinc Alloys: Annealing or heat treating at 400–1000°C? 1100°C provides ample headroom.

- Soft Magnetic Materials: Like iron-based alloys, benefiting from low-temp annealing to enhance magnetic traits.

Chemical Reagents and Catalysts

- Catalyst Precursors: Oxides or salts calcine or activate at 1100°C to yield fine particles.

- Inorganic Salts: Carbonates or sulfates often decompose in this range for thermal studies.

Ceramics and Minerals (With Limitations)

- Low-Melt Ceramics: Basic clays or glazes that sinter near 1000°C find a perfect match.

- Mineral Samples: Quartz or clay for thermal analysis or prep work.

When to Skip the 1100°C Muffle Furnace

For these scenarios, upgrade to higher temps like 1400°C or 1700°C:

- Sintering high-purity alumina or zirconia ceramics;

- High-temp crystal growth or powder sintering;

- Processes needing SiC or MoSi₂ elements;

- Demanding apps with sustained runs over 1000°C and ultra-precise control.

Why Opt for CVSIC’s 1200°C Muffle Furnace?

With decades in furnace fabrication, CVSIC’s advice is straightforward: “Skip the high-heat chase—pick the range that fits your process.”

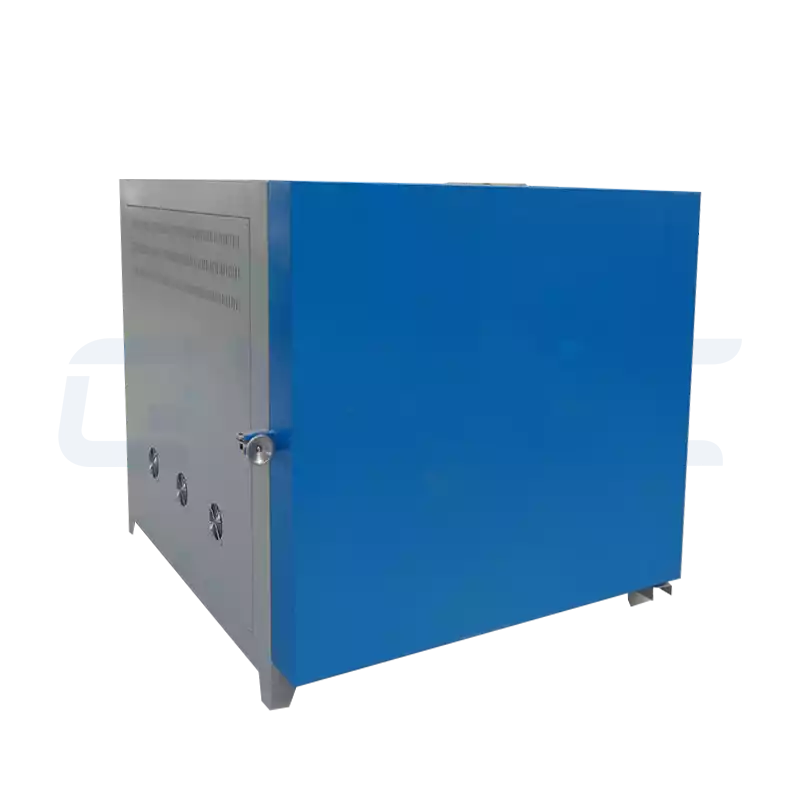

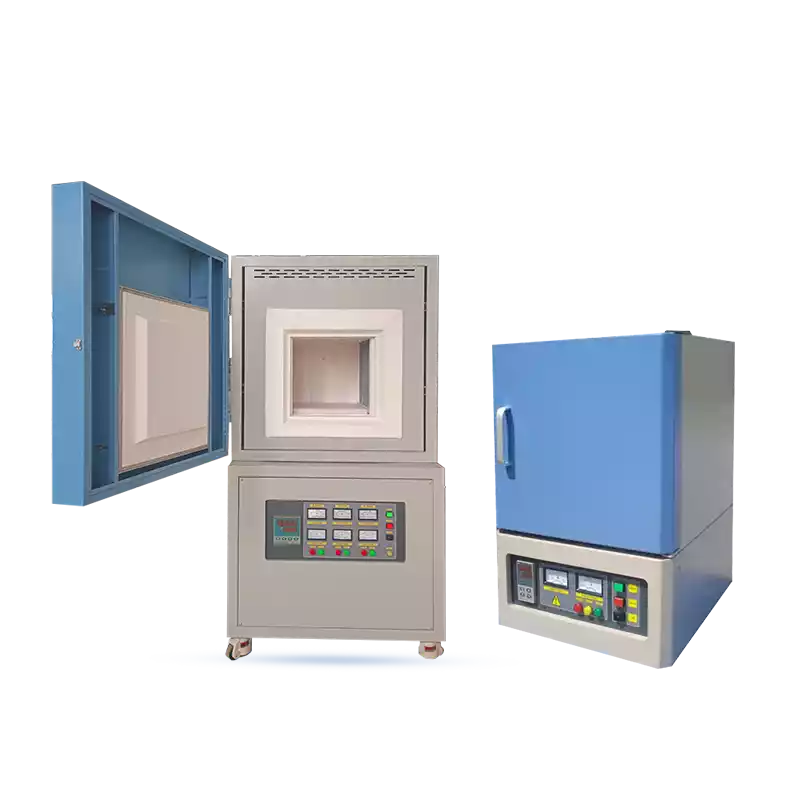

Our 1200°C models are the smart, economical pick for entry-level labs and light industrial tasks. Compact, energy-efficient, and low-maintenance, they’re tailored for universities, R&D centres, and factory QA teams. Choose from volumes like 1L, 8L, 30L, or 100L to suit your samples and space—plus OEM/ODM customisation.

Engineered for lab reliability, they run steadily at 1100°C long-term, blending affordability with performance:

- Cost-Effective: Budget-friendly resistance wire for value-driven buyers.

- User-Centric: Intuitive controls let novices hit the ground running.

- Safe and Reliable Overheat safeguards and alarms provide peace of mind during extended operation.

- Hassle-Free Upkeep: Simple wire swaps, backed by CVSIC guides and support.

Selection Tips for 1100°C Models

Broad utility aside, keep these in mind:

- Verify Temp Needs: Near-1100°C runs can wear resistance wire faster—our 1200°C option extends life while meeting demands.

- Chamber Sizing: Go 1–10L for small-scale; CVSIC offers flexible options for varying loads.

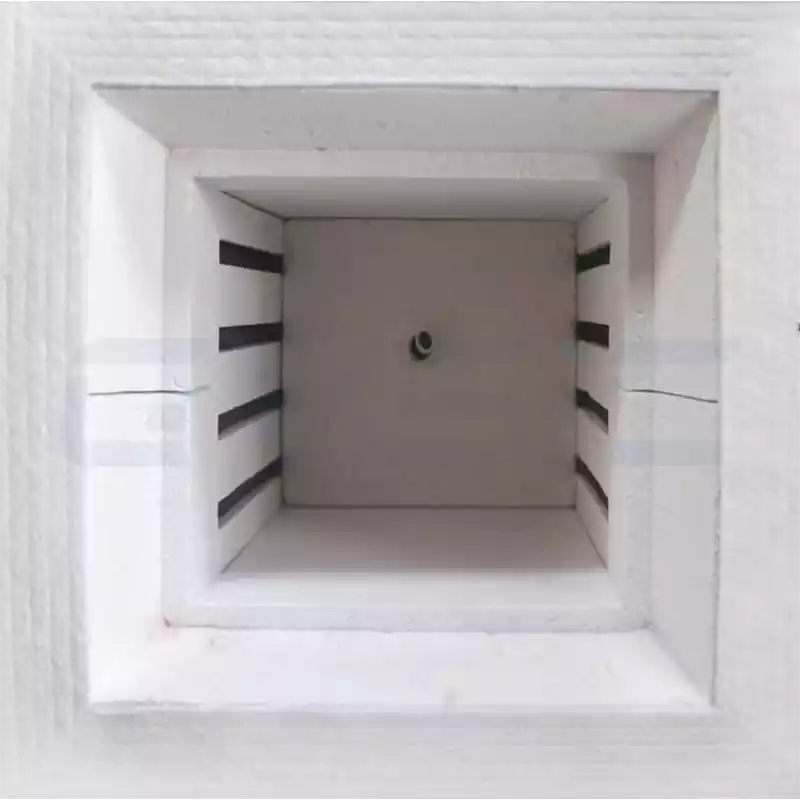

- Material Fit: Pick corrosion-resistant linings like alumina to match your samples.

- Precision Controls: Our PID systems lock in stability for exacting work.

Unsure about 1100°C? Reach out to the CVSIC team—we’ll tailor advice to your setup and even facilitate trials.

In Summary: The 1100°C Muffle Furnace—A Lab All-Rounder

Versatile and reliable, the 1100°C muffle furnace excels at analysis, drying, annealing, and decomposition for a wide range of materials, making it a valuable all-in-one lab solution.

CVSIC’s 1200°C lineup prioritizes user-friendly design, precise control, and solid support to simplify operations for lab professionals and industrial users. Whether you’re new to high-temperature equipment or an experienced pro, the right furnace turns good experiments into great ones. Got specific lab or process needs? Drop a comment—I’m here to help!

FAQ

Can a 1100°C muffle furnace sinter ceramics?

Yes, for pre-sintering or binder burnout. For full densification, opt for 1400°C Muffle Furnaces.

Can it run continuously?

Absolutely. CVSIC’s 1100°C units, with durable resistance wire, sustain 8+ hours at rated temps via smart controls.

Big gap between 1100°C and 1200°C furnaces?

Mainly in element durability and insulation longevity. For heavy, prolonged use, go to 1200°C.

Suitable for alumina sintering?

Good for pre-sintering or surface work, but densification demands ≥1600°C.