Debinding, prior to sintering, is crucial for reliably removing binders from MIM, CIM, and powder metallurgy products. Binders temporarily hold powders together and must be removed entirely to ensure product integrity after sintering.

New users often overlook debinding. Incomplete or rushed debinding can cause porosity, cracking, or part failure during sintering. The debinding furnace is crucial for process quality and yield.

CVSIC outlines the principles, main types, applications, and selection tips for debinding furnaces.

What is a Debinding Furnace?

A debinding furnace removes binders from molded parts in MIM, CIM, and powder metallurgy. This allows the parts to sinter with the proper strength and density.

The operation of a debinding furnace hinges on three core principles:

- Controlled Heating: Gradual temperature increases prevent excessive internal stress in parts.

- Atmosphere or Vacuum Processing: Nitrogen, hydrogen, vacuum, or catalytic atmospheres accelerate binder decomposition and volatilization.

- Exhaust Management and Purification: Decomposition byproducts are safely extracted to ensure environmental compliance and operational safety. In essence, a debinding furnace must thoroughly remove binders while preserving the integrity of the part itself.

Common Debinding Processes

Different debinding processes suit varying applications. Below is a comparison of four widely used methods:

Solvent Debinding

- Principle: Organic solvents (e.g., trichloroethylene) dissolve the binder at low temperatures (room temperature to 100°C).

- Advantages: Low-temperature operation and fast processing, ideal for delicate or deformation-prone materials.

- Disadvantages: High costs for waste liquid disposal and stringent environmental regulations.

- Applications: Laboratories or small-batch production.

Thermal Debinding

- Principle: Heating (200°C–550°C) decomposes the binder, which escapes gradually, typically in an inert atmosphere, such as nitrogen.

- Advantages: Simple equipment design and broad applicability.

- Disadvantages: Longer processing times and higher energy consumption.

- Applications: Powder metallurgy and small to medium-scale production.

Catalytic Debinding

- Principle: Acidic catalysts (e.g., nitric acid vapor) accelerate binder decomposition at lower temperatures (150°C–250°C).

- Advantages: Fast processing with minimal residue, ideal for high-volume production.

- Disadvantages: Requires handling of acidic gases and specialized equipment.

- Applications: High-precision MIM components.

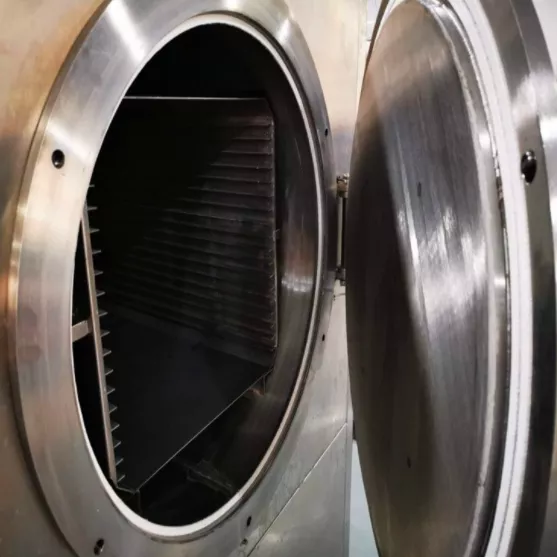

Vacuum Debinding

- Principle: Heating in a vacuum environment (up to 600°C) extracts volatile substances.

- Advantages: Oxidation-free, environmentally friendly, suitable for reactive metals like titanium alloys, with residual carbon levels below 0.1%.

- Disadvantages: Complex equipment and higher maintenance costs.

- Applications: High-end MIM or aerospace materials.

How to Select the Right Debinding Process?

Choose based on material and production scale. Solvent debinding suits small batches. Use catalytic or vacuum debinding for large-scale work. CVSIC offers free process evaluations to find your best option.

Types of Debinding Furnaces

Debinding furnaces are categorized into four main types based on structure and application:

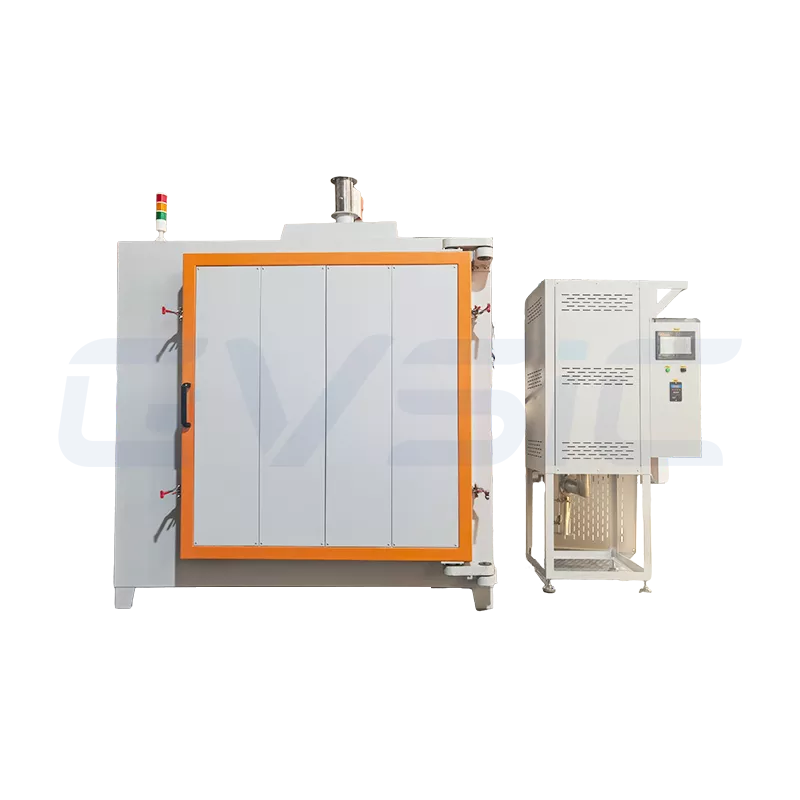

Box-Type Debinding Furnace

- Simple design and flexible operation, albeit with lower efficiency, make this suited for batch production.

- Ideal for laboratory or small-scale MIM/CIM processes.

Tube-Type Debinding Furnace

- Tubular design enables continuous heating with uniform temperature and precise atmosphere control.

- Commonly used in research institutions or medium-scale powder metallurgy production.

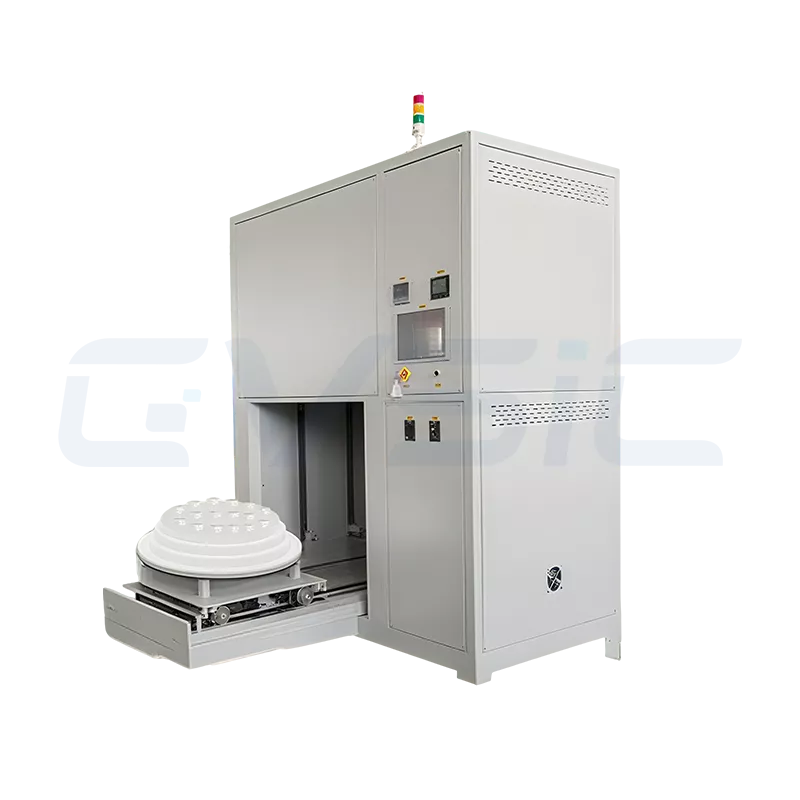

Vacuum Debinding Furnace

- Operates in a high-vacuum environment, ideal for industries requiring oxidation-free processing.

- Frequently used for precision parts and medical device MIM products.

Continuous Debinding Furnace

- Integrates debinding and material transport for high efficiency, making it ideal for large-scale production.

- Best suited for large MIM or powder metallurgy facilities.

Which Furnace is Right for My Facility?

Match your capacity and budget. For small operations, choose box-type or tube-type furnaces. Use continuous or vacuum furnaces for large-scale or high-precision work. CVSIC offers customized selection advice.

Applications of Debinding Furnaces

Debinding furnaces serve a wide range of industries:

MIM (Metal Injection Molding)

- Applications: Complex metal parts for mobile devices, medical instruments, and more.

- Requirements: High-precision temperature control and low residual carbon in MIM debinding furnaces.

CIM (Ceramic Injection Molding)

- Applications: Ceramic knives, electronic components, and similar products.

- Requirements: Precise control of heating rates to prevent cracking.

Powder Metallurgy

- Applications: High-strength components like gears and bearings.

- Requirements: High-capacity furnaces with continuous production capabilities.

Can Debinding Furnaces Be Used Across Industries?

Yes. CVSIC furnaces support MIM, CIM, and powder metallurgy applications for multiple materials.

How to Choose the Right Debinding Furnace?

Selecting the ideal debinding furnace involves evaluating several key factors:

- Temperature Range: Typically 200–600°C, with some processes requiring up to 1000°C.

- Atmosphere Control: Options include nitrogen protection, hydrogen reduction, or oxygen-free vacuum, depending on process requirements.

- Production Capacity: Is it for laboratory R&D, pilot production, or large-scale manufacturing?

- Safety Features: Essential for catalytic and solvent debinding, including exhaust treatment and explosion-proof designs.

- Total Cost of Ownership: Beyond equipment cost, consider expenses for gas, electricity, and maintenance.

CVSIC Recommendations

- For Newcomers: Start with small box-type or tube-type debinding furnaces for flexible process validation.

- For Scaled Production: Prioritize continuous or vacuum debinding furnaces to enhance efficiency and product quality.

How can I select a cost-effective debinding furnace on a limited budget?

Define your capacity and process needs, and opt for modular furnace designs. CVSIC can tailor solutions to fit your budget.

FAQ

Can debinding and sintering be performed in the same furnace?

Yes. Integrated debinding-sintering furnaces are available and work effectively for small or space-limited operations. For large-scale production, separate the processes to achieve greater flexibility.

Why do my parts crack during the debinding process?

Rapid heating, excessive binder, or unstable atmospheres can cause cracking. Adjust your heating curve and stabilize the furnace atmosphere.

Which is better for MIM: vacuum or catalytic debinding furnaces?

Vacuum debinding is suitable for medical and precision parts. Catalytic debinding is more efficient for large-scale MIM. Choose based on your product.

What are the main operating costs of a debinding furnace?

Costs primarily stem from electricity, gas consumption (e.g., nitrogen, hydrogen), exhaust treatment, and routine maintenance.

Does CVSIC offer customized debinding furnaces?

Yes. We design furnaces to your required capacity, process, and atmosphere, as well as sintering and atmosphere solutions.

Conclusion

The debinding furnace is crucial for product yield, accuracy, and performance. It determines if you can succeed at mass production.

CVSIC delivers solutions from lab to industrial scale. Begin by assessing your production needs, reviewing your current debinding challenges, and scheduling a consultation to identify the most cost-effective and high-performance furnace for your specific applications. Contact us for guidance on new or existing production lines.