In modern experimentation and industrial production, the muffle furnace stands as one of the most essential high-temperature devices.

Whether for scientific ash analysis, material sintering, or metal heat treatment, muffle furnaces are virtually ubiquitous. They meet researchers’ demands for precise temperature control while supporting industrial users’ continuous production needs.

This article, authored by the CVSIC High-Temperature Engineering Team, will help you understand the working principles, temperature ratings, application differences, and selection logic of muffle furnaces, providing reliable high-temperature solutions for your projects.

Muffle Furnace Definition and Working Principle

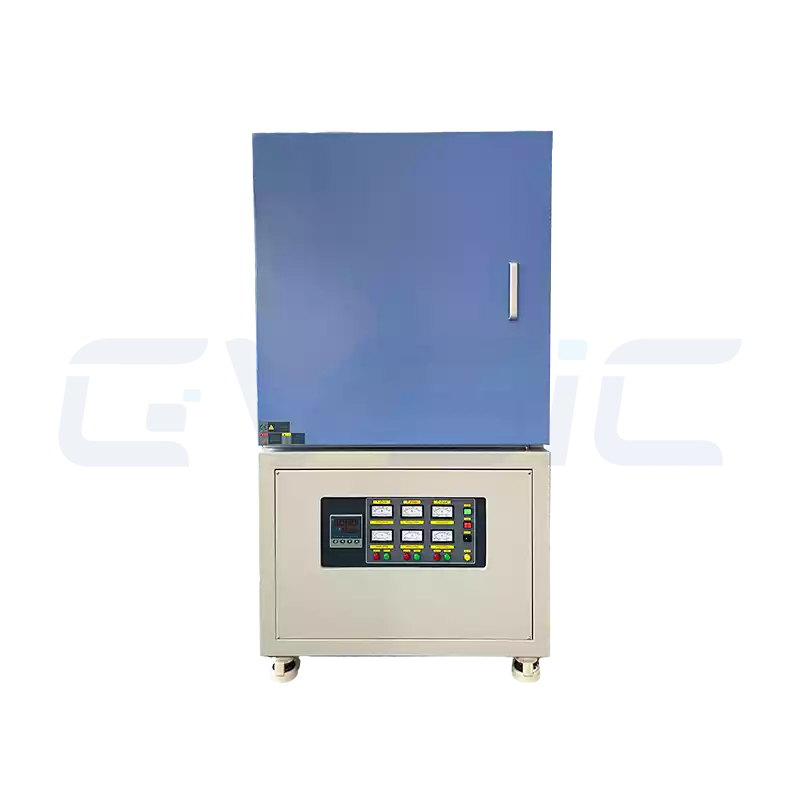

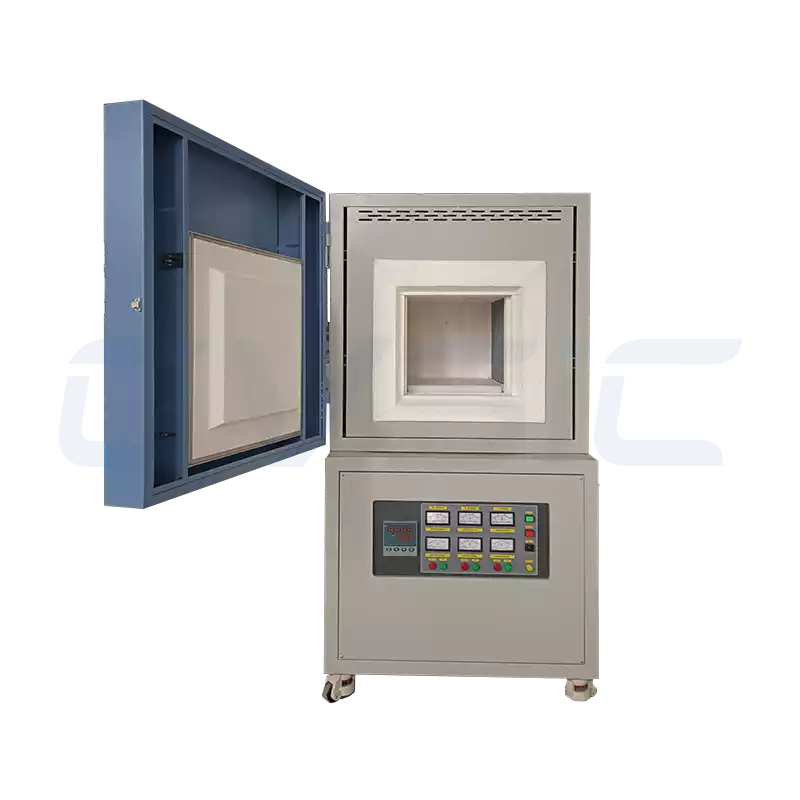

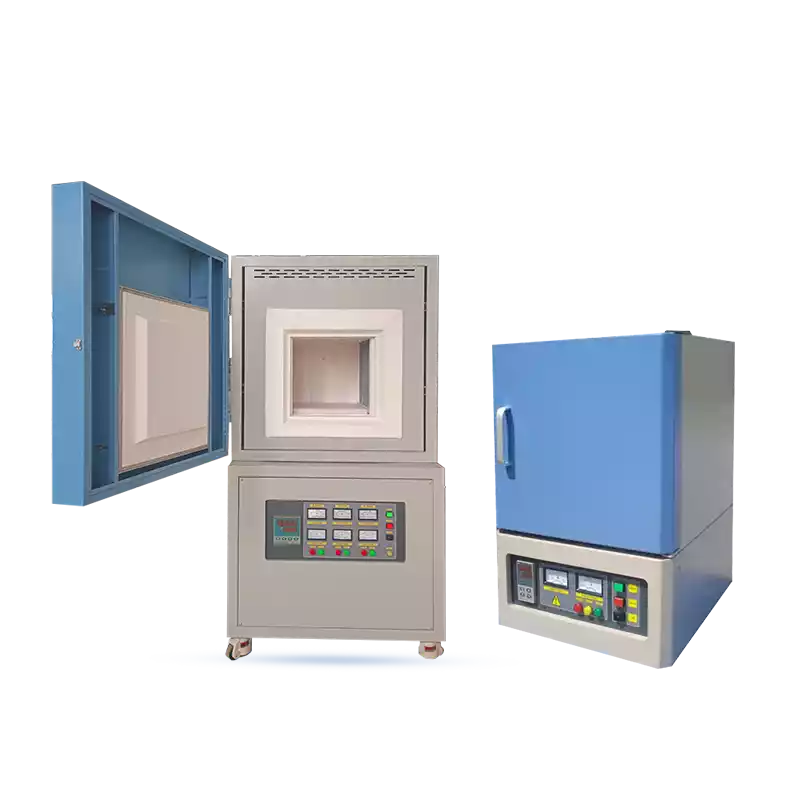

A muffle furnace, also called a box furnace, is a sealed high-temperature heating device for laboratories and industry. It is designed to deliver precise heating inside an isolated chamber. This protects processes from outside interference.

Key components of a muffle furnace include:

- Chamber (Furnace Lining): Crafted from refractory materials to maintain a uniform temperature field, providing a stable space for sample placement.

- Insulation Layer: Fiber blankets or ceramic boards that reduce heat loss.

- Heating Elements: The core system, generating heat using resistance wires, SiC, or MoSi2 Heaing elements, each chosen for specific temperature ranges.

- Control System: PID controllers or touchscreens precisely regulate temperature.

The working principle is simple and effective. Electrical current powers heating elements to produce heat. This creates an independent high-temperature zone inside the muffle chamber, which prevents outside contamination. Unlike standard electric furnaces, muffle furnaces focus on isolated heating. This makes them very reliable for sensitive materials.

Heat transfer in muffle furnaces combines radiation and convection. Radiation delivers energy directly, similar to sunlight. Convection circulates air and distributes heat evenly. This combination creates superior temperature uniformity compared to regular electric furnaces. In my experience, it reduces hot spots in samples and helps prevent failed experiments. Uneven heating could leave half of a ceramic batch perfectly sintered, while the other half is underdone—a real problem avoided.

Muffle Furnace Temperature Ranges and Heating Element Comparisons (1100°C to 1800°C)

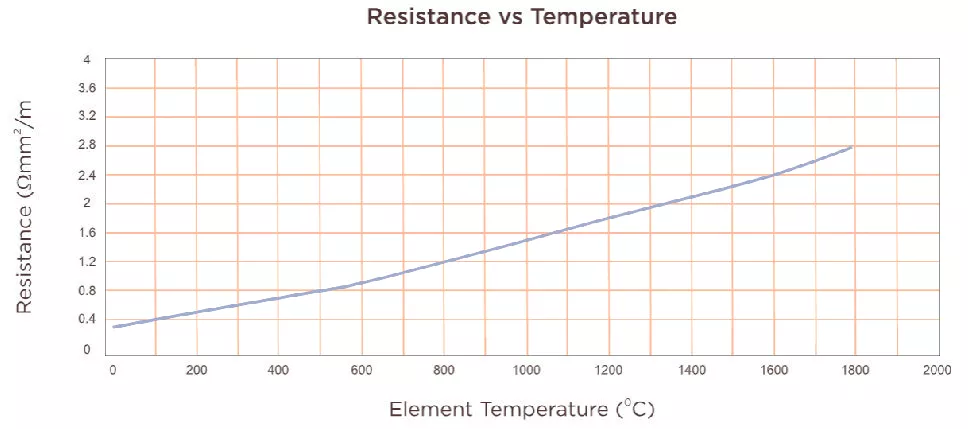

Muffle furnaces reach 1100°C to 1800°C, with performance tied to the heating element. Choosing correctly prevents overheating and ensures proper temperatures. Here are the three main types.

Resistance Wire Muffle Furnaces (≤1200°C)

- Ideal Applications: Laboratory analysis, ashing, drying, and low-temperature annealing.

- Advantages: Affordable, straightforward design, and easy to maintain—perfect for budget-conscious users.

- Disadvantages: Shorter service life; not suited for prolonged high-temperature operations.

- Engineering Insight: Resistance wires oxidize at high temperatures, forming insulating oxide that raises resistance and reduces efficiency. Control ramp-up rates and ensure good ventilation to prolong life.

SiC Heating Element Muffle Furnaces (1200–1600°C)

- Ideal Applications: Ceramic sintering, metal annealing, and powder sintering.

- Advantages: SiC elements offer rapid heating and high thermal efficiency, reaching target temperatures swiftly to conserve energy.

- Disadvantages: Moderate oxidation resistance requires protective measures in humid conditions.

Relative to resistance wires, SiC elements deliver an extended lifespan and quicker thermal response for more reliable performance.

| Parameter | Resistance Wire Furnace | SiC Furnace |

| Max Temperature | ≤1200°C | ≤1600°C |

| Ramp-Up Speed | Slow | Fast |

| Lifespan | Short | Medium |

| Cost | Low | Medium |

Pro Tip: For continuous high-temperature processes, SiC heating elements provide the stability and cost savings you need.

CVSIC SIC Heating Element Muffle Furnace Sales

MoSi2 Heating Element Muffle Furnaces (1700–1800°C)

- Ideal Applications: High-temperature ceramic experiments, glass melting, and advanced materials research in institutes.

- Advantages: Exceptional oxidation resistance for steadfast operation in extreme heat.

- Disadvantages: Higher upfront cost, with material brittleness demanding careful handling during installation.

At high temperatures, the surface of Molybdenum Disilicide Heating elements forms a dense SiO₂ protective film that effectively blocks further oxidation, enabling reliable long-term operation in extreme heat. Above 1600°C, MoSi₂ exhibits the least performance degradation, making it a standout choice for demanding research applications.

| Heating Element | Max Temperature | Lifespan (Hours) | Thermal Response Time (to 1200°C) |

| Resistance Wire | ≤1200°C | 500–1000 | Slow (30–60 min) |

| SiC | 1200–1600°C | 2000–5000 | Fast (10–30 min) |

| MoSi₂ | 1700–1800°C | 3000–8000 | Medium (15–40 min) |

As the table illustrates, SiC strikes the best balance of performance and value for mid-range temperatures—a go-to benchmark I rely on when guiding clients through selections.

Volume Selection Guide (1L–1000L)

Chamber volume directly impacts your loading capacity, so it’s worth getting right: a mismatch can result in wasted space or overcrowded samples. Drawing from years of hands-on experience, I’ll break it down into three practical categories.

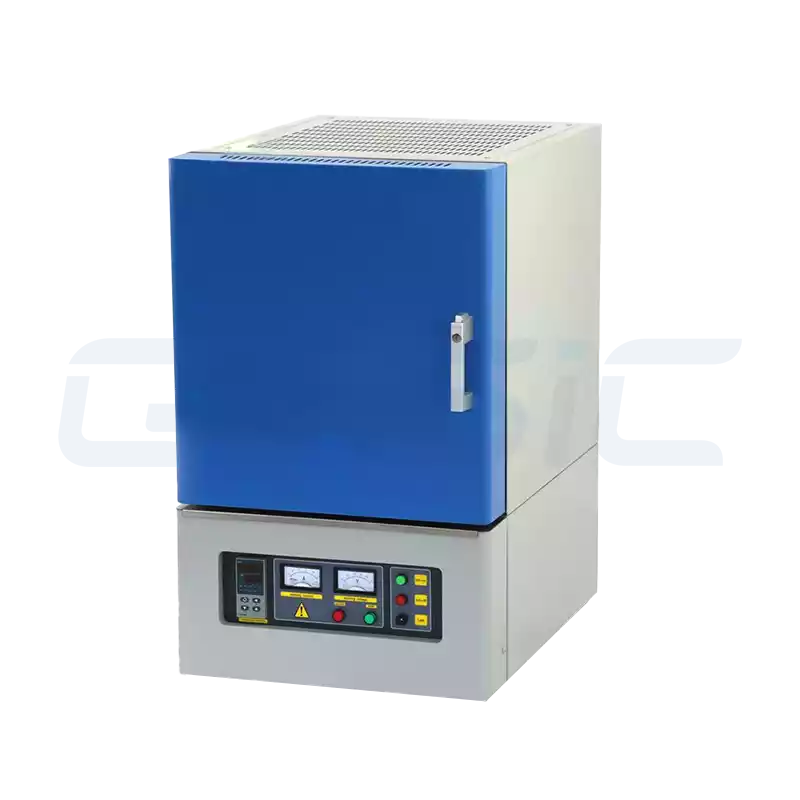

1–10L: Compact Furnaces

- Typical Applications: Laboratories and analytical centers.

- Key Benefits: Rapid heating, space-saving design, ideal for single-sample workflows.

For sizing, use the sample volume reference below to match chamber capacity to your needs:

| Sample Type | Recommended Volume |

| Small Ceramics | 1–3L |

| Metal Samples | 3–5L |

| Chemical Ashing | 5–10L |

10–200L: Mid-Sized Furnaces

- Typical Applications: Pilot production lines and materials R&D centers, striking a smart balance between precision and throughput.

- Key Benefits: Balanced capacity for efficient process validation or small-batch testing.

Think of compact models as a portable toolkit—handy for precision work—while mid-sized ones resemble a compact fridge, offering significantly more room for scaled-up testing without sacrificing control.

200–1000L: Large-Scale Furnaces

- Typical Applications: Industrial production lines, batch sintering, and heat treatment facilities.

- Key Insight: These models prioritize superior temperature zone uniformity and precise heat distribution for consistent large-volume results.

Laboratory vs. Industrial Muffle Furnaces: Key Differences and Selection Guide

Lab furnaces excel in precision, while industrial ones deliver high throughput. Use this quick comparison to inform your choice:

| Aspect | Laboratory Furnace | Industrial Furnace |

| Heating Element | Resistance Wire / SiC | SiC / MoSi₂ |

| Control System | Basic PID | PLC Automation |

| Cabinet Design | Benchtop | Vertical / Floor-Standing |

| Primary Focus | Precision | Capacity & Durability |

Takeaway: Choose laboratory models if maximum precision and repeatability are essential for experimental consistency. Select industrial-grade furnaces when your operations require robust performance, large-scale capacity, and extended service life. Decide based on the primary need: fine accuracy versus high volume and durability.

Muffle Furnace Applications Across Industries

Ceramics Industry

Essential for sintering and glaze melting. The sintering profile profoundly influences material density—a gradual temperature ramp reduces porosity, enhancing overall strength and reliability.

Metals and Metallurgy

Core processes include annealing, brazing, and heat treatment. Protective atmosphere (e.g., inert gases) combined with multi-zone temperature control effectively limits oxidation, optimizing metallurgical properties.

Glass Manufacturing

Critical for softening and forming. SiO₂ undergoes structural transitions at key temperatures (e.g., 573°C from α to β quartz), where precise furnace control prevents defects like cracking.

Chemical Analysis and R&D

In ashing and sample preparation, precise temperature control guarantees reproducible outcomes—a 1°C difference can skew results, so reliability is essential.

How to Choose the Right Muffle Furnace Model and Temperature Range

No need to overthink it—here’s a straightforward five-step checklist (print and tick off as you go):

- Define Your Application: Is it analysis, sintering, or melting?

- Set Your Temperature Needs: Align with elements (e.g., ≤1200°C for resistance wire).

- Size for Capacity: Scale to your sample volume.

- Pick Controls: PID for basics or PLC for advanced?

- Factor in Efficiency: Choose CVSIC for energy-smart, long-life designs.

Match your needs with this handy reference table:

| Application | Temperature Range | Recommended Element | CVSIC Model |

| Lab Analysis | ≤1200°C | Resistance Wire | CVSIC 1200 Compact Muffle Furnace |

| Ceramic Sintering | 1200–1600°C | SiC | CVSIC 1700 Muffle Furnace |

| Glass Melting | 1700–1800°C | MoSi₂ | CVSIC 1800 Muffle Furnace |

OEM/ODM and Customization Services

Beyond standard models, CVSIC provides adaptable OEM and ODM partnerships for your specifications.

- OEM Services: Tailor logos, aesthetics, and packaging for seamless brand integration.

- ODM Services: Refine furnace structures, control systems, and insulation based on your requirements.

Choose chamber materials, door orientation, interfaces, or multi-zone setups.

FAQ

How long can a muffle furnace run continuously?

Runtime depends on heating element: resistance wire ~1000 hours, SiC ~2000 hours, MoSi₂ >3000 hours.

Does chamber material impact heating efficiency?

Yes. High-purity alumina linings increase uniformity and thermal shock resistance.

Can it operate in an inert atmosphere?

Standard models use air; an inert gas setup is available via customization.

What’s the difference in control systems between lab and industrial furnaces?

Lab: PID for tuning. Industrial: PLC for automation and data control.

Can you accommodate custom sizes or temperature specs?

We offer full customization from 1L–1000L volumes and 1100°C–1800°C temperatures.