Rotary vs. Fixed Tube Furnaces: Choosing the Ideal Solution for Your Process

When processing powder materials, issues like clumping, uneven heating, or low yields can disrupt your workflow.

Rotary and fixed tube furnaces address these challenges, each excelling in specific applications. This guide from CVSIC simplifies their differences, pros, and cons to help you select the best furnace for your needs.

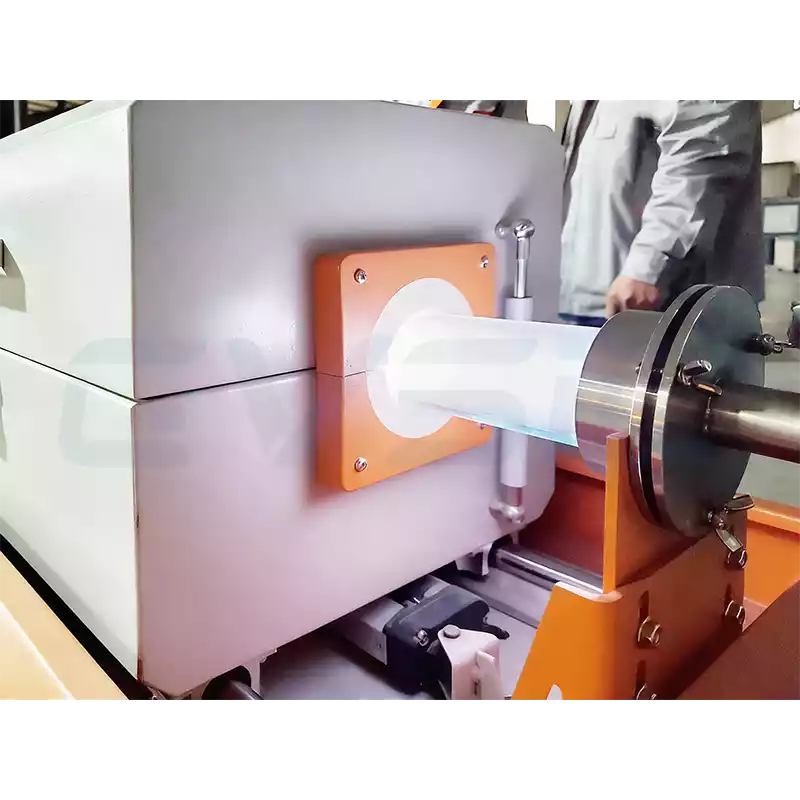

Rotary Tube Furnace: The Dynamic “Mixing Master”

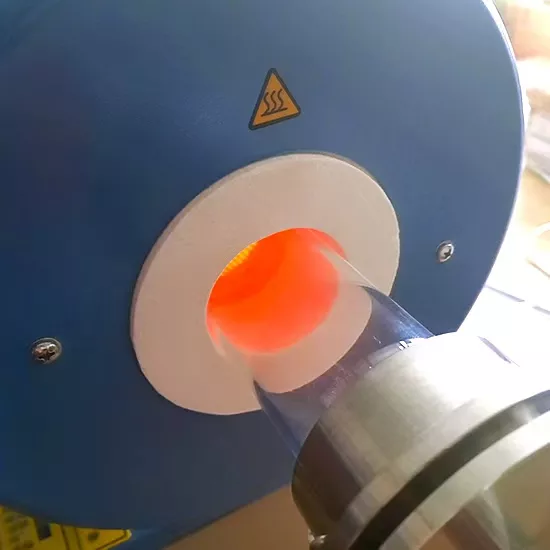

Rotary tube furnaces feature a rotating tube, typically spinning at a few to dozens of revolutions per minute, keeping samples in constant motion like a high-temperature mixer. Heating elements, evenly distributed around the tube, combine with this rotation to deliver consistent heating across the sample.

Advantages of Rotary Tube Furnaces

- Uniform Heating: Continuous sample tumbling prevents localized overheating or clumping, ensuring consistent results.

- Efficient Mixing: Ideal for dynamic reaction processes like catalyst preparation or powder sintering, delivering stable, high-quality outcomes.

- Versatile Design: Adjustable rotation speed and tilt angle accommodate a wide range of materials.

Disadvantages of Rotary Tube Furnaces

- Complex Maintenance: The rotation mechanism, including bearings and motors, requires regular upkeep, increasing maintenance demands.

- Higher Energy Use: The rotating system consumes 5-10% more energy than fixed furnaces due to additional power needs.

- Not for Static Samples: Unsuitable for experiments requiring stationary samples, such as thin film deposition.

Ideal Applications

- Continuous sintering or calcination of powder materials

- Catalyst carrier preparation

- Uniform reactions for battery materials or ceramic powders

- High-volume production or processes requiring dynamic mixing

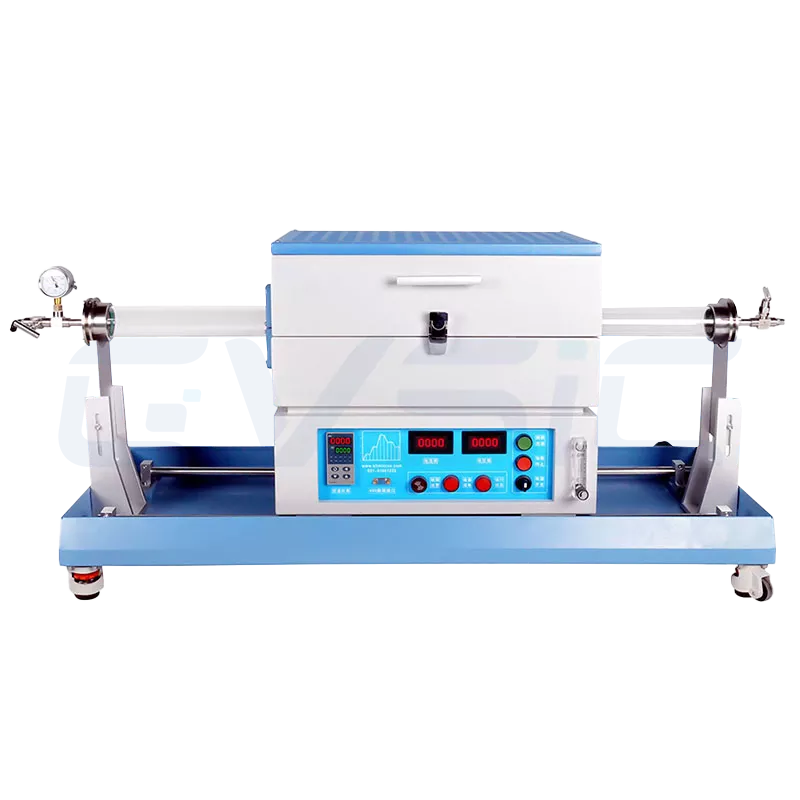

Fixed Tube Furnace: The Reliable, Classic Choice

Fixed tube furnaces have a stationary tube. Samples are placed in boats or crucibles for static heating. The simple design, with heating elements around the tube, provides uniform temperature. CVSIC’s fixed furnaces are stable and easy to use for labs and industry.

Advantages of Fixed Tube Furnaces

- User-Friendly Operation: Simple loading, heating, and unloading processes make them ideal for beginners or high-frequency experiments.

- High Reliability: With no moving parts, they offer low failure rates and minimal maintenance costs.

- Versatile Functionality: Support for vacuum, atmosphere control, and multi-zone configurations suits a wide range of processes, from annealing to CVD.

Disadvantages of Fixed Tube Furnaces

- Risk of Uneven Heating: Powder samples may clump or heat unevenly without manual intervention, which can potentially affect the results.

- Limited for Dynamic Processes: Less effective for applications requiring continuous mixing, such as powder sintering.

Ideal Applications

- Thin film deposition (e.g., CVD, PVD)

- Annealing, heat treatment, or crystal growth

- Small-scale or static experiments (e.g., semiconductor material processing)

Comparative Overview: Rotary vs. Fixed Tube Furnaces

| Structural Complexity | Simple, low-maintenance design | Complex, with higher maintenance needs due to mechanical components |

| Temperature Uniformity | Dependent on sample loading method | Enhanced by rotation for consistent material heating |

| Operational Convenience | Intuitive, ideal for single-batch experiments | Requires speed and angle adjustments, with a slight learning curve |

| Sample Adaptability | Best for block or static samples | Ideal for powders, granules, or continuous materials |

| Applications | Routine lab sintering, atmosphere processing | Catalyst preparation, powder sintering, continuous reactions |

| Expandability | Supports multi-zone, vacuum, and atmosphere control | Offers automated loading/unloading and online monitoring options |

| Cost Factors | Cost-effective and versatile | Higher initial cost, but superior efficiency for specific processes |

Purchase high-performance tube furnaces from Chinese tube furnace manufacturer

How to Choose the Right Tube Furnace?

Consider these guidelines to make an informed decision:

- Routine Lab Heat Treatment: Opt for a fixed tube furnace.

- Powder or Catalyst Research: Choose a rotary tube furnace.

- High-Volume Continuous Processes: Select a rotary tube furnace.

- Limited Budget: Go with a fixed tube furnace.

- Focus on Efficiency and Consistency: Prioritize a rotary tube furnace.

Expert Insight: For small-scale research and limited sample sizes, use a fixed-tube furnace. For powder R&D or pilot production, a rotary tube furnace gives higher efficiency and uniformity.

FAQ

Is a rotary tube furnace always better than a fixed tube furnace?

Not necessarily. Rotary furnaces excel in powder processing and continuous workflows, but fixed furnaces are more practical and cost-effective for block samples or single-batch experiments.

Does a rotary tube furnace compromise atmosphere sealing?

Not with a robust design. CVSIC’s rotary flanges and sealing systems ensure reliable atmosphere protection during rotation.

Are maintenance costs high for rotary tube furnaces?

Slightly higher due to motors and mechanical components, but with regular maintenance, CVSIC furnaces offer years of reliable performance.

Can fixed tube furnaces handle powder sintering?

Yes, but manual sample turning may be required to prevent clumping. For large powder volumes, rotary furnaces are more efficient.

How significant is the cost difference between rotary and fixed furnaces?

Rotary furnaces are approximately 5-10% more expensive due to dynamic components, but their efficiency gains make them cost-effective for powder-based processes over time.