What is a Tube Furnace? Your Gateway to High-Temperature Applications

Tube furnaces are essential high-temperature heating systems widely used in materials science, metallurgy, semiconductors, and nanotechnology. Renowned for their controllable atmospheres, precise temperature regulation, and versatile designs, they meet the diverse needs of research and industry. In this guide, CVSIC provides a comprehensive overview of tube furnaces, covering their principles, classifications, applications, and comparisons with other types of furnaces.

Core Principles of Tube Furnaces: The Key to Precision Heating

A tube furnace consists of heating elements (devices that generate heat, such as silicon carbide rods, MoSi2 Heating elements, or resistance wires), insulation materials that keep the heat inside, and a tube-shaped chamber. Its operation works as follows:

- When the heating elements are powered on, they generate controlled heat.

- The tube chamber is the space where samples are placed, often in containers made of quartz (a hard, heat-resistant glass), corundum (a durable crystal), or metals. This design allows heat to distribute evenly around the samples.

- The atmosphere control system lets you introduce gases such as nitrogen (an inert gas), argon (another inert gas), hydrogen, or water vapor into the furnace, or remove air to create a vacuum. This helps tailor the environment for specific experiments.

- The temperature control system, which uses intelligent electronic controllers, lets users set precise temperatures for heating up, holding, and cooling down samples in the furnace.

Unlike basic heating devices, a tube furnace creates a controlled environment for chemical reactions or high-temperature processes. Its flexibility allows it to work with inert gases—gases that do not react, such as nitrogen or argon—or to create a vacuum (an airless space), which helps prevent unwanted reactions, such as oxidation, or supports experiments requiring special conditions.

Types of Tube Furnaces

Tube furnaces come in various configurations, each tailored to specific applications. Let CVSIC guide you through our product lineup to simplify your selection process.

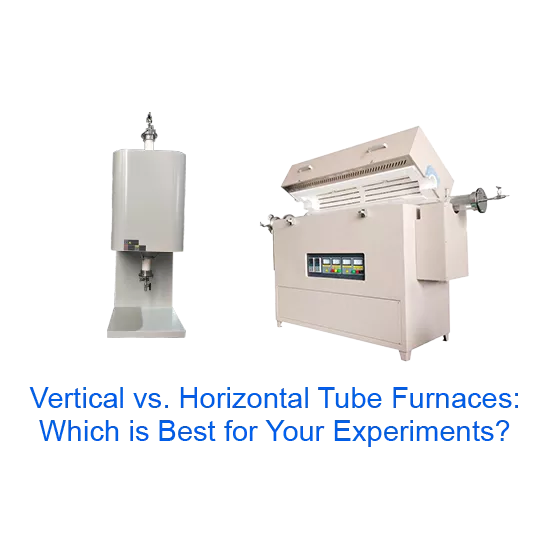

Vertical Tube Furnace

With a vertically oriented tube, samples are loaded from the top or bottom, making it ideal for space-constrained laboratories.

The natural rise of hot air creates a temperature gradient, which is ideal for crystal growth or gravity-assisted processes, such as powder sintering or sedimentation experiments.

Applications: Deposition, sintering, and atmosphere-controlled experiments. Note: Care must be taken during sample loading to prevent spills.

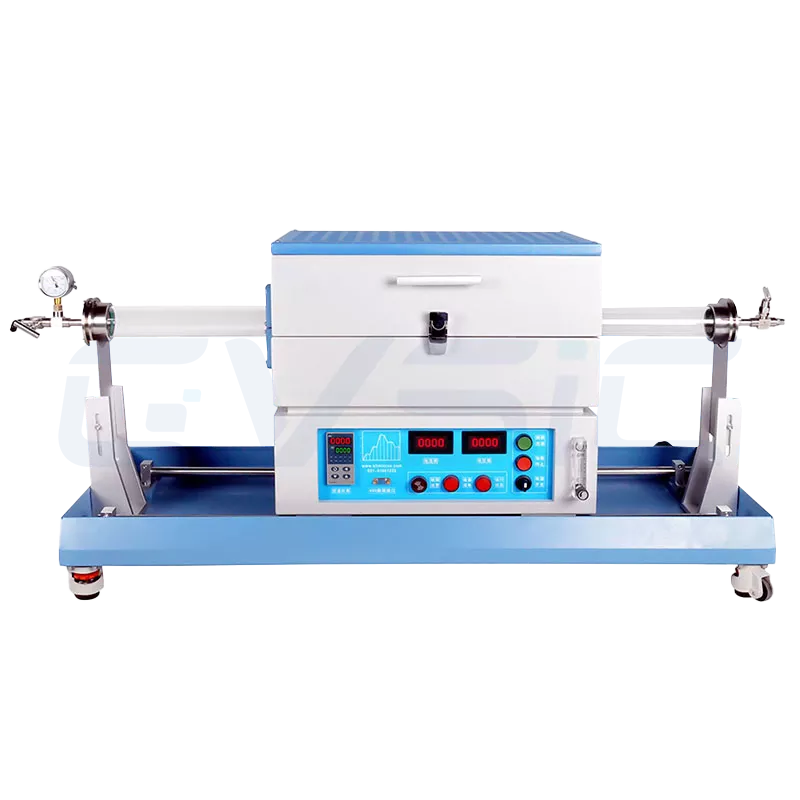

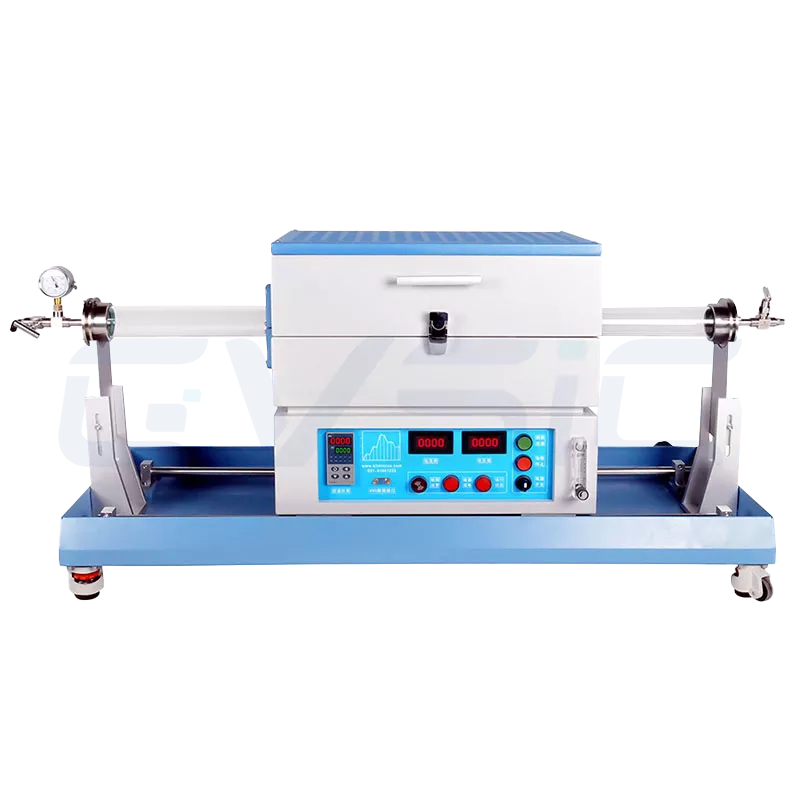

Horizontal Tube Furnace

Featuring a horizontally placed tube, this type offers ease of operation and uniform heating, making it suitable for most heat treatment tasks, such as annealing or sintering.

Its design ensures convenient sample loading and consistent atmosphere flow, ideal for frequent material handling.

Applications: Heat treatment, materials research, and semiconductor processes.

Rotary Tube Furnace

Designed for powder materials, this furnace features a rotating tube, ideal for ceramics or pharmaceutical sintering processes.

Rotation ensures even powder mixing, preventing clumping and promoting uniform heating.

Applications: Powder processing, catalyst preparation, and activated carbon activation.

Steam Activation Tube Furnace

This specialized furnace introduces water vapor to facilitate the synthesis of oxides or the preparation of catalysts.

While steam enhances specific chemical reactions, robust sealing and corrosion-resistant materials are critical.

Applications: Activated carbon production, carbon-based material modification, and new energy research.

Multi-Zone Tube Furnace

This furnace features multiple heating zones, each controlled separately, allowing different parts of the tube to be maintained at distinct temperatures.

This is useful for processes such as chemical vapor deposition (CVD), a method for creating thin films, or heating samples in a temperature gradient.

Applications: Advanced materials synthesis and controlled thermal processes.

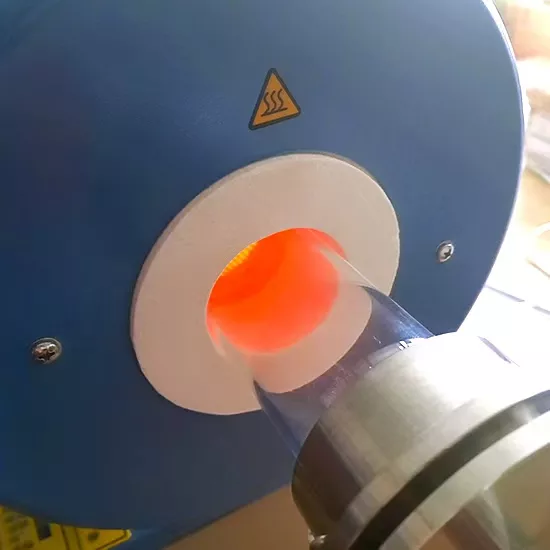

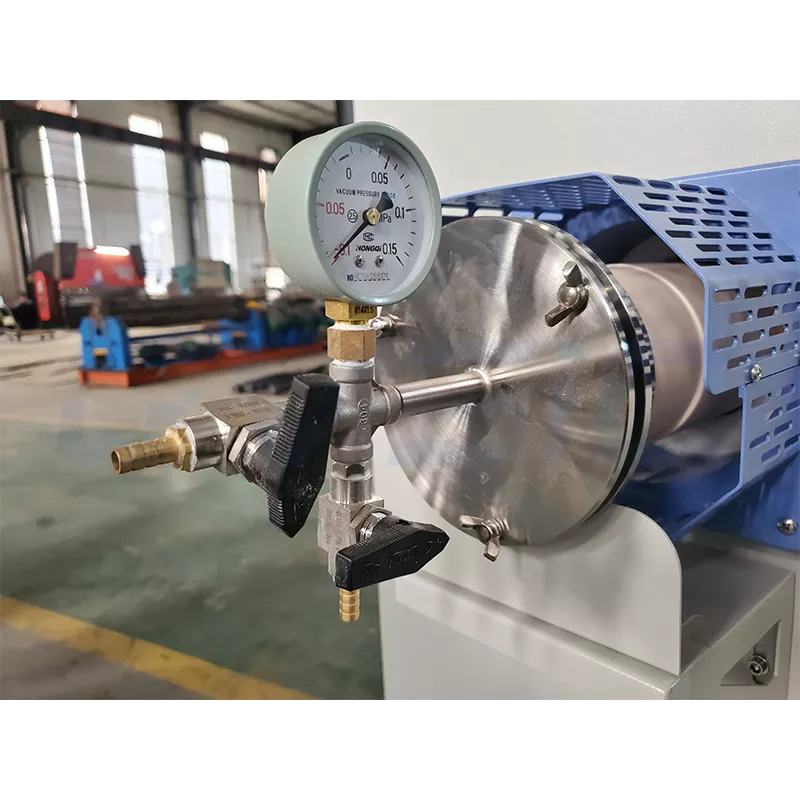

Vacuum Tube Furnace

Fitted with a vacuum pump and sealing system, this furnace achieves high vacuum levels (up to 10^-3 Pa), preventing sample oxidation.

It’s ideal for high-purity applications, such as metal annealing and semiconductor research. Regular vacuum pump maintenance is essential.

Applications: Semiconductor processing and high-purity material treatments.

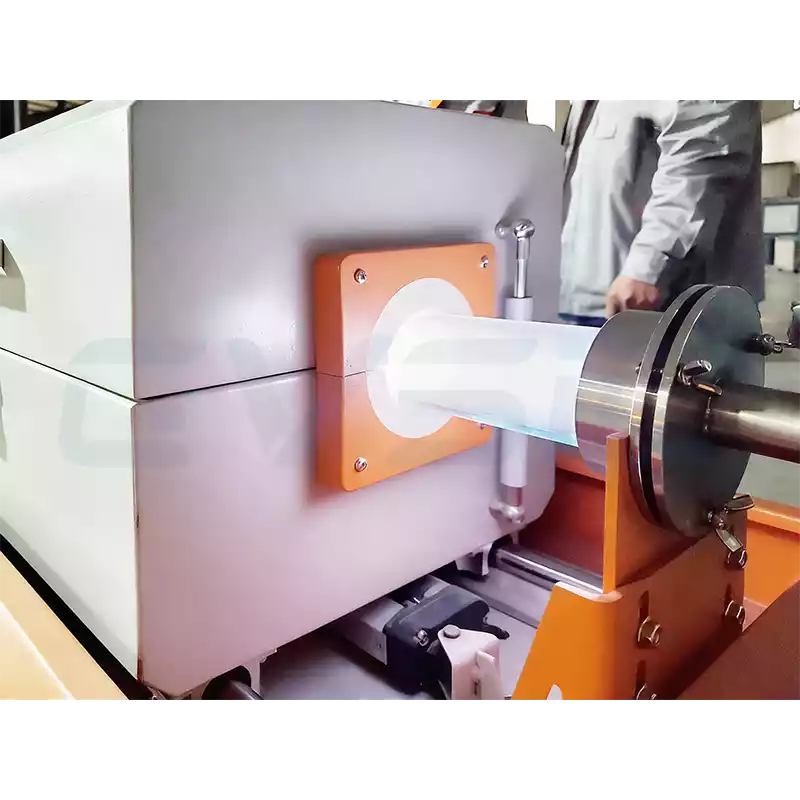

Sliding Tube Furnace

Designed with a sliding furnace body or cooling system, this model enables rapid sample cooling, making it suitable for quenching, rapid heat treatments, or physical property studies.

Applications: Quenching and advanced material research.

CVD Tube Furnace

CVD tube furnaces deposit films on substrates through high-temperature chemical reactions. Furnace tubes are typically horizontal or vertical, equipped with precise gas control systems. Operating at elevated temperatures (typically 600-1200°C), they suit material deposition requiring high-temperature catalysis.

The deposited films exhibit dense structures and high purity, making them suitable for large-area uniform coatings. The furnace can accommodate multiple reaction gases (e.g., methane, silane), offering high flexibility.

Typical applications include graphene fabrication, carbon nanotube growth, ceramic coating, semiconductor device manufacturing, and high-temperature materials research.

High-temperature operation demands stringent furnace tube materials, requiring robust sealing and exhaust gas treatment to prevent hazardous gas leakage.

PECVD Tube Furnace

PECVD tube furnaces achieve high-quality thin film deposition at lower temperatures by introducing plasma to enhance chemical reactions. Equipped with RF or microwave plasma sources, these furnaces activate reaction gases and reduce deposition temperatures (typically 200-500°C), making them suitable for materials sensitive to high heat.

Compared to conventional CVD, PECVD’s low-temperature process protects substrates, offers faster deposition rates, and ensures superior film uniformity. The furnace tube is typically horizontal in design, featuring a vacuum system and gas flow control, making it suitable for precision experiments.

Widely used for semiconductor film deposition (e.g., silicon-based films, oxide films), solar cells, optical coatings, and nanomaterial preparation.

Plasma equipment is complex, requiring regular maintenance of electrodes and vacuum systems. Safety precautions must be observed during operation to avoid RF radiation exposure.

Applications of Tube Furnaces

From Labs to Industry, Tube furnaces are remarkably versatile, delivering exceptional performance across various sectors. Here are some key applications:

- Materials Research: Synthesize advanced alloys, ceramics, or composites with precise temperature and atmosphere control.

- Heat Treatment: Perform annealing, quenching, or other processes to enhance material properties, especially in metalworking.

- Powder Sintering and Activation: Achieve uniform particle formation in ceramics or metal powders, with rotary furnaces ensuring consistency.

- Atmosphere-Controlled Experiments: Use protective gases like hydrogen or argon for reactions, critical in lithium battery and hydrogen energy material development.

- Nanomaterials: Employ CVD or PVD processes to create nanotubes or nanowires, with multi-zone furnaces leading the way.

- Semiconductors: Support diffusion and oxidation processes for high-purity chip production, ensuring 24/7 operational stability.

Purchase high-performance tube furnaces from tube furnace manufacturer

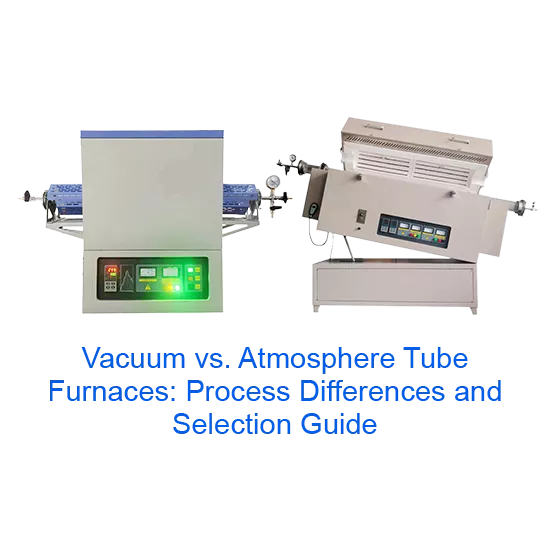

Tube Furnace vs. Other Furnaces: Which Suits Your Needs?

Tube furnaces offer unique advantages but differ from other types of furnaces. Below is a comparison of muffle and box furnaces to guide your decision.

| Comparison Item | Tube Furnace | Muffle Furnace | Box Furnace |

| Structure | Tubular chamber with atmosphere control | Box-shaped chamber | Box-shaped chamber |

| Atmosphere Control | Supports vacuum and gas inputs | Typically air atmosphere | Typically air atmosphere |

| Temperature Uniformity | Excellent in-tube uniformity | Good uniformity | Good uniformity |

| Applications | Research, semiconductors, powders | Ash testing, material analysis | Industrial heat treatment, large samples |

| Flexibility | Multi-zone, vacuum, fast-cooling options | Limited functionality | Large chamber for bulk processing |

Key Takeaways

- Tube Furnace: Ideal for research and precision material processing.

- Muffle Furnace: Best for testing and educational experiments.

- Box Furnace: Suited for large-scale industrial production and bulk processing.

In summary, recognizing the differences between furnace types ensures the right match for your needs. Tube furnaces, with their controllable atmospheres, precise temperature regulation, and versatile configurations, are indispensable in materials science, metallurgy, semiconductors, and new energy applications. Choose based on your own operational demands: flexibility, routine testing, or industrial-scale production.

When selecting a research-grade or industrial tube furnace, consider your specific needs, including the temperature range, atmospheric requirements, heating rates, and types of samples. Models like vertical, horizontal, multi-zone, vacuum, or rotary furnaces ensure optimal results for both research and production.

FAQ

Is a tube furnace suitable for beginners?

Absolutely! Horizontal tube furnaces are user-friendly and ideal for newcomers. We recommend learning safety protocols, such as wearing protective gloves and avoiding contact with hot surfaces. CVSIC provides comprehensive beginner guides to ensure a smooth start.

What is the maximum temperature of a tube furnace?

Typically ranging from 1,200 °C to 1,800 °C, depending on the model. CVSIC’s vacuum series exceeds 1700°C, catering to high-performance applications.

How can I extend the lifespan of a tube furnace?

Regularly clean the furnace tube to prevent dust buildup, inspect heating elements every 6-12 months, and maintain intact seals. CVSIC’s maintenance kits simplify upkeep.

Can a tube furnace operate in a vacuum environment?

Yes, vacuum tube furnaces can achieve high vacuum levels (up to 10^-3 Pa), making them ideal for processing high-purity materials. Regular vacuum pump maintenance is advised.

Is a tube furnace more energy-efficient than a box furnace?

Due to their low thermal mass and rapid heating, tube furnaces are generally more energy-efficient. Actual energy consumption depends on usage frequency, but tube furnaces often offer long-term savings.