Introduction: Why Differentiate Between Vacuum and Atmosphere Debinding Furnaces?

Customers often ask whether to choose a vacuum debinding furnace or an atmosphere debinding furnace. (Debinding is the process of removing binder material from molded parts before sintering.)

The answer depends on your specific product requirements.Vacuum debinding furnaces serve applications needing oxidation-free processing, superior surface quality, and environmental compliance.When cost control, process maturity, and high production volume are most important, atmosphere debinding furnaces provide a cost-effective solution.

Now, let’s examine the key differences between these furnace types to guide your decision.

Core Differences: How They Work

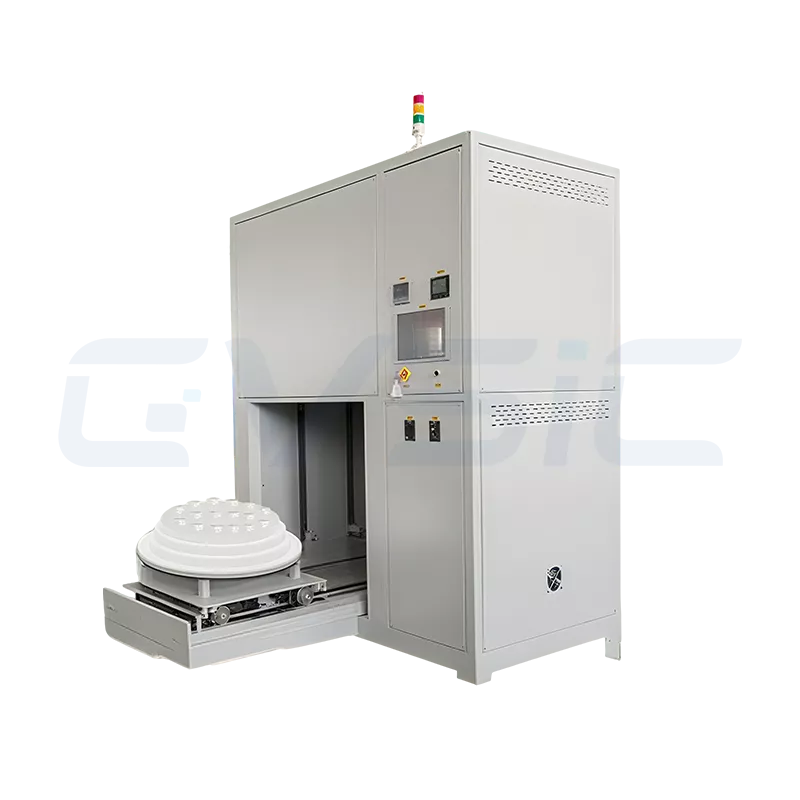

Vacuum Debinding Furnace

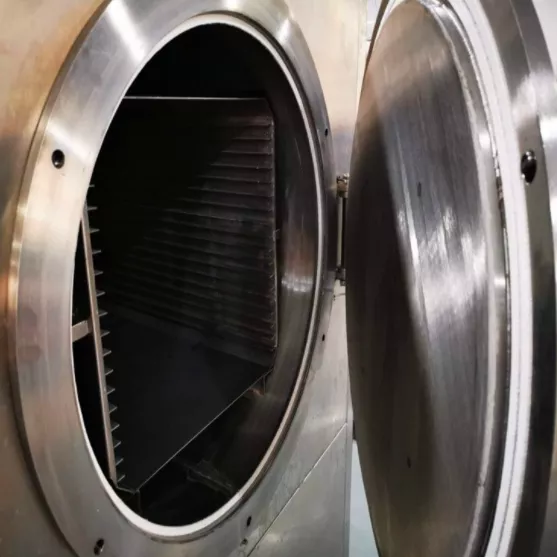

- Operates in a high-vacuum environment (typically below 10⁻² Pa) at temperatures ranging from 200°C to 600°C, utilizing a vacuum pump to extract volatilized binders, thereby preventing oxidation or contamination.

- Its oxygen-free environment is ideal for highly reactive metals (such as titanium and magnesium, which easily react with oxygen) or precision components.

Atmosphere Debinding Furnace

- Heats at 200°C–550°C under protective inert gases (e.g., nitrogen, argon) or reducing gases (e.g., hydrogen), with decomposed binders carried away by gas flow.

- Offers a controllable atmosphere suitable for various materials but requires a steady gas supply and exhaust treatment.

Key Insight: Vacuum debinding furnaces excel in preventing oxidation and ensuring cleanliness, while atmosphere debinding furnaces prioritize process stability and efficiency.

Which is Better for High-Precision MIM Parts?

Vacuum debinding furnaces are the preferred choice for high-precision MIM (metal injection molding) applications, as they minimize oxidation and residual carbon (the binder remaining after debinding), providing superior quality for demanding industries.

Performance Comparison: Efficiency and Quality

Vacuum Debinding Furnace

- Efficiency: Debinding is slightly slower due to the time required for vacuum pumping, but it delivers consistent quality.

- Product Quality: Achieves extremely low residual carbon, making it ideal for high-demand sectors like aerospace and medical devices. For example, CVSIC assisted a medical device manufacturer in optimizing a vacuum furnace, boosting their product pass rate from 90% to 99%.

- Limitation: For larger components, vacuum pumping can extend processing time, resulting in a slight reduction in efficiency.

Atmosphere Debinding Furnace

- Efficiency: Faster debinding, ideal for high-volume production, with gas circulation accelerating the removal of volatiles.

- Product Quality: The residual carbon (the percentage of binder left after debinding) is slightly higher (0.2%–0.5%), but this is sufficient for most powder metallurgy applications.

- Limitation: Inconsistent gas purity (variation in the quality of the protective or reducing gases) may cause minor oxidation, necessitating regular monitoring of the gas source.

Which is Best for High-Output Factories?

For facilities focused on efficiency and high throughput, atmosphere debinding furnaces are the preferred option. CVSIC’s continuous atmosphere furnaces can increase production capacity by up to 40%.

Obtain custom degreasing furnaces from CVSIC

Application Scenarios: Which Suits Your Needs?

Vacuum Debinding Furnace

- Typical Applications: Highly reactive metals (e.g., titanium alloys), precision MIM parts, aerospace components, high-end electronic ceramics, and products requiring exceptional surface quality and minimal defects.

- Advantages: Ideal for materials sensitive to residual carbon and oxidation, ensuring top-tier quality.

- Case Study: An aerospace client utilized a CVSIC vacuum debinding furnace to produce defect-free titanium alloy components, resulting in a 20% reduction in delivery times.

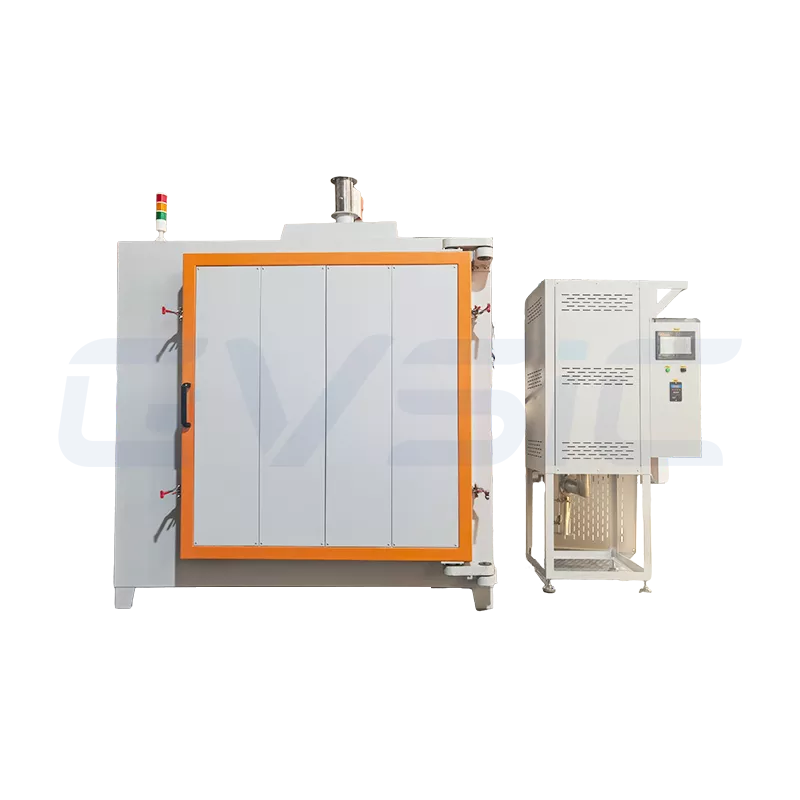

Atmosphere Debinding Furnace

- Typical Applications: Powder metallurgy (forming parts from powdered metals), automotive parts (mass production), ceramic injection molding (CIM—similar to MIM, but using ceramic powders), medium- to low-precision MIM parts, and products with moderate surface quality requirements.

- Advantages: Highly adaptable, supporting a wide range of materials and large-scale production.

Key Insight: Vacuum furnaces are suited for high-end, custom applications, while atmosphere furnaces excel in scalable, cost-effective production.

Common Question: Is a vacuum debinding furnace necessary for ceramic (CIM) parts?

Not always. An atmosphere debinding furnace is typically sufficient for CIM (ceramic injection molding), unless your ceramics demand extremely low residual carbon. CVSIC offers free process testing to confirm the best approach for your needs.

Process Characteristics Comparison

| Oxidation Control | Completely oxidation-free | Relies on protective atmosphere |

| Debinding Speed | Slower | Faster |

| Surface Quality | Superior, excellent cleanliness | Good, but atmosphere-dependent |

| Investment Cost | High | Moderate |

| Operating Cost | Electricity + vacuum pump maintenance | Electricity + gas consumption |

| Safety | High (no flammable gases) | Moderate (requires safe handling of gases like hydrogen) |

Cost and Maintenance: Balancing Investment and Returns

Vacuum Debinding Furnace

- Initial Cost: Higher due to the complexity of the equipment, including vacuum pumps and sealing systems.

- Operating Cost: No gas consumption, but higher electricity use and specialized maintenance.

- Maintenance Focus: Regularly inspect vacuum pumps and sealing rings.

- Return on Investment: Best for high-value products, offering significant long-term quality benefits.

Atmosphere Debinding Furnace

- Initial Cost: Lower, with simpler designs suitable for small to medium-sized enterprises.

- Operating Cost: High consumption of nitrogen or hydrogen, plus costs for exhaust purification systems.

- Maintenance Focus: Regular filter replacement and inspection of gas pipelines.

- Return on Investment: Ideal for large-scale, cost-sensitive production, delivering quick returns.

How to Choose the Right Furnace?

- Choose a Vacuum Debinding Furnace: If you produce high-precision, high-value products (e.g., aerospace or medical MIM parts) requiring minimal residual carbon and zero oxidation, and you have the budget to support it.

- Choose an Atmosphere Debinding Furnace: If your focus is on high output, cost efficiency, and moderate residual carbon requirements (e.g., automotive parts or CIM), or if your facility already has a gas supply system in place.

- CVSIC Tip: Start by defining your process needs rather than focusing solely on price. Selecting the right furnace can significantly boost yield and overall economic benefits.

Conclusion

The choice between vacuum and atmosphere debinding furnaces isn’t about which is superior—it’s about which aligns with your goals. Consider whether your priority is exceptional surface quality and stability or cost-effectiveness and production capacity.

As a trusted provider of industrial electric heating solutions, CVSIC offers customized vacuum and atmosphere debinding furnaces, along with expert process development support. If you’re planning an MIM or CIM production line, contact us today for tailored guidance.