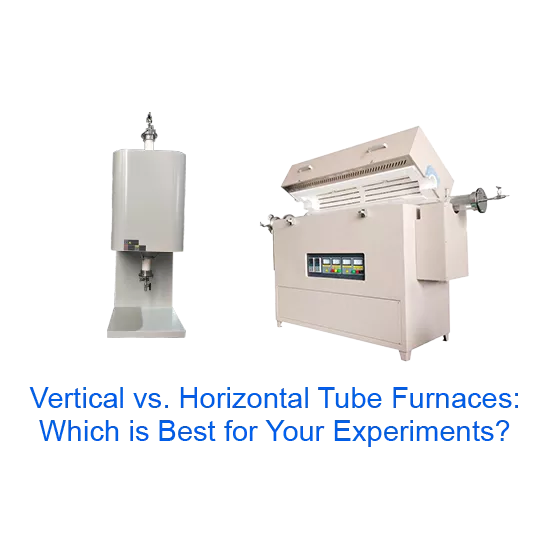

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments

Sample oxidation or contamination in high-temperature experiments can compromise results. Selecting the appropriate tube furnace is essential for optimal process outcomes. Vacuum and atmosphere tube furnaces serve as cornerstone technologies in high-temperature systems, with each offering distinct advantages for targeted applications.

Before we delve into the specifics, let’s examine how these two distinct furnace types compare in terms of process features, advantages, limitations, and typical applications. Following our detailed comparison, CVSIC will provide clear selection advice tailored to your needs, ensuring you find the perfect high-temperature solution.

Vacuum Tube Furnace: The High-Purity “Oxygen-Free Champion”

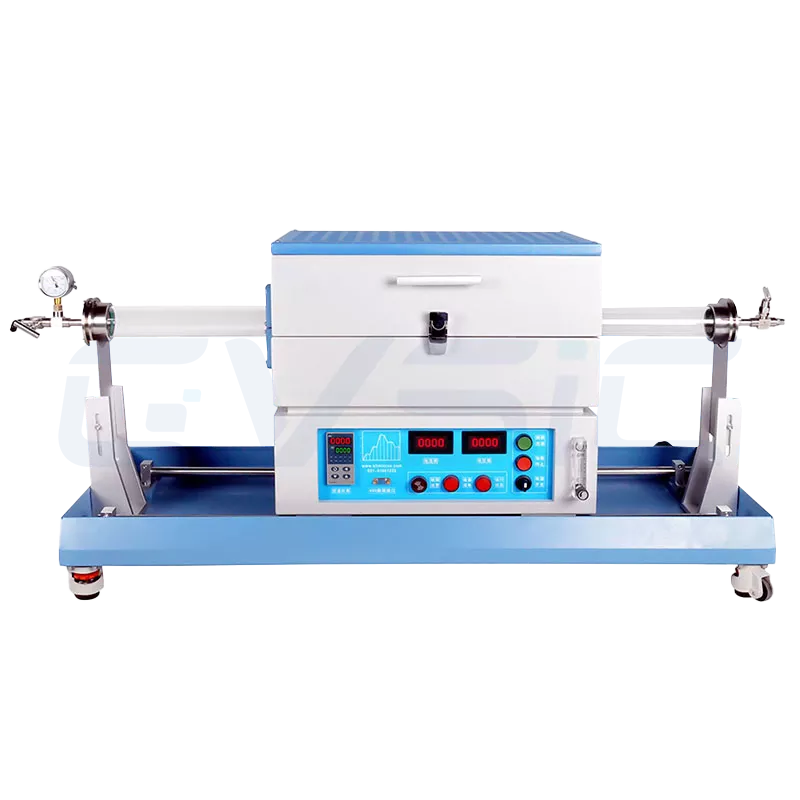

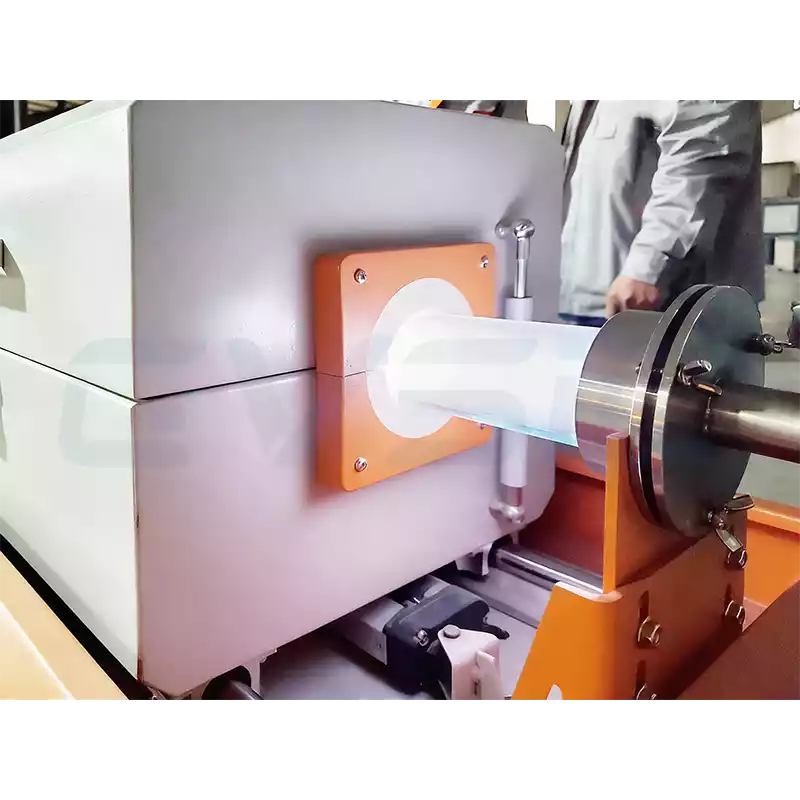

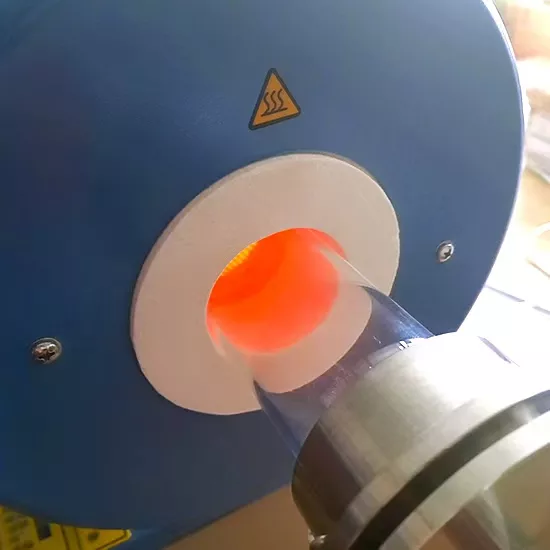

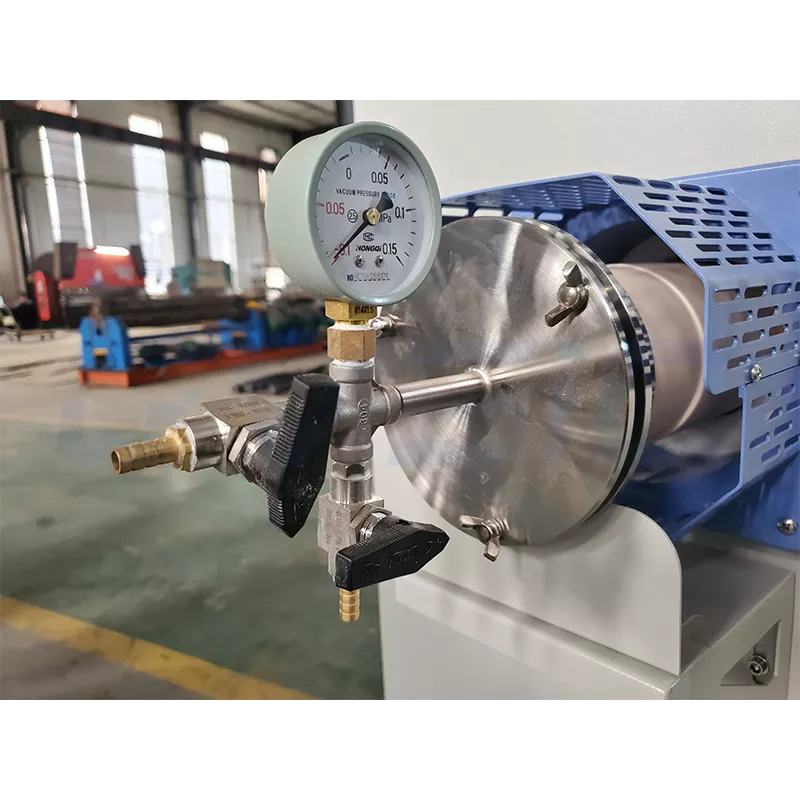

Vacuum tube furnaces utilize a vacuum pump to create a low-pressure environment (10⁻¹ to 10⁻⁵ Pa), thereby heating samples in an oxygen-free and impurity-free environment. Durable quartz or corundum tubes and tight seals stop outside gases from entering.

Advantages of Vacuum Tube Furnaces

- Exceptional Purity: The vacuum environment eliminates oxidation and contamination, ideal for ultra-high-purity experiments.

- Precision Control: Without gas interference, temperature distribution is highly uniform, ensuring excellent repeatability for processes like CVD or PVD.

- High-Temperature Performance: Capable of exceeding 1800°C, suitable for processing high-melting-point materials.

Disadvantages of Vacuum Tube Furnaces

- High Maintenance Costs: Vacuum pumps and seals require regular upkeep, which can be complex. Neglecting maintenance, such as pump oil changes, may compromise vacuum levels and experimental results.

- Higher Initial Investment: The vacuum system increases costs, a consideration for budget-conscious labs.

- Operational Complexity: Vacuuming and depressurizing add steps, often requiring training for new users.

Ideal Applications

- Semiconductor processes (e.g., thin film deposition, diffusion)

- High-purity material synthesis (e.g., oxide single crystals)

- Oxidation-free high-temperature experiments (e.g., titanium alloy heat treatment)

- Micro-interface reaction studies

Atmosphere Tube Furnace: The Versatile “Gas Flow Expert”

Atmosphere tube furnaces introduce gases such as nitrogen, argon, or hydrogen to create specific environments, thereby protecting samples or enabling targeted reactions. Their sealing and tube materials withstand varied chemical atmospheres.

Advantages of Atmosphere Tube Furnaces

- Versatile Gas Use: Inert gases (such as argon) prevent oxidation, while reactive gases (like hydrogen) facilitate targeted reactions.

- User-Friendly Operation: Simple vacuum systems feature intuitive gas flow control, making them ideal for frequent experiments.

- Cost-Effective: Offers lower initial and maintenance costs compared to vacuum furnaces, making it a budget-friendly option.

Disadvantages of Atmosphere Tube Furnaces

- Limited Purity: Protective gases reduce impurities, but trace oxygen or contaminants may persist, making the environment less pure than a vacuum environment.

- Sealing Demands: Gas leaks can disrupt experiments, necessitating regular inspections of flanges and seals to ensure optimal performance.

- Gas Costs: The continuous use of high-purity gases, such as argon, can lead to increased operational expenses.

Ideal Applications

- Metal powder sintering (nitrogen, argon protection)

- Catalyst preparation (hydrogen, ammonia, reducing atmospheres)

- Carbon material research

- Battery anode/cathode material heat treatment

Comparative Overview: Vacuum vs. Atmosphere Tube Furnaces

| Environmental Control | High vacuum, nearly impurity-free | Gas displacement, purity depends on gas source |

| Anti-Oxidation Capability | Superior, ideal for high-temperature oxidation prevention | Effective with protective gases, but less thorough than vacuum |

| Process Adaptability | Ideal for degassing, vacuum sintering, interface studies | Suited for reducing, inert, or specialized reaction atmospheres |

| Equipment Complexity | Complex vacuum system, higher cost | Simpler design, lower cost |

| Operational Convenience | Requires vacuuming and pressurizing, more involved | Intuitive gas flow control, user-friendly |

| Application Range | Aerospace materials, semiconductors, functional ceramics | Metal heat treatment, powder metallurgy, catalyst preparation |

Real-World Examples: Vacuum vs. Atmosphere in Action

To highlight their differences, here are two CVSIC client success stories:

- Vacuum Furnace Success: A leading semiconductor manufacturer sought high-purity silicon thin films, where oxygen presence risked product defects. By implementing CVSIC’s vacuum tube furnace at a pressure of 10^-4 Pa, the company reliably produced flawless silicon films, resulting in a 30% increase in yield. The engineering team confirmed, “The vacuum furnace revolutionized our production outcomes.”

- Atmosphere Furnace Success: An advanced energy laboratory focused on lithium battery research required nitrogen-protected sintering for cathode materials. Utilizing CVSIC’s atmosphere tube furnace with precise gas flow control, the lab achieved a 20% enhancement in material performance. The project leader reported, “Its efficient operation doubled our experimental output.”

Purchase high-performance tube furnaces from Chinese tube furnace manufacturer

Selection Guide

To make the right choice, consider these factors:

- Prioritize Oxidation Prevention and Ultra-High Purity: Choose a vacuum tube furnace.

- Require Specific Atmospheres (e.g., Nitrogen, Hydrogen): Opt for an atmosphere tube furnace.

- Research-Focused, Interface or Specialty Materials: Select a vacuum tube furnace.

- Industry-Focused, Protective Sintering or Reduction: Go with an atmosphere tube furnace.

- Budget Constraints: Atmosphere tube furnaces are more cost-effective.

CVSIC provides advanced, integrated vacuum and atmosphere solutions, including protocols that combine vacuum processing with subsequent nitrogen or argon filling. This approach unites high-purity environments with precise atmosphere control, enabling customers to excel in both research and production.

FAQ

How do their temperature capabilities compare?

Both furnaces offer similar ranges, determined by heating elements and insulation. CVSIC’s vacuum and atmosphere furnaces support processes from 1200°C to 1700°C.

What vacuum levels can vacuum tube furnaces achieve?

CVSIC’s models typically reach 10^-3 Pa, with advanced configurations achieving 10^-5 Pa, depending on the vacuum pump.

Can atmosphere tube furnaces replicate vacuum conditions?

No, they rely on gas displacement and cannot match the impurity-free environment of a vacuum pump.

How complex is vacuum furnace maintenance?

Regular inspection of pumps and seals is critical for optimal vacuum furnace performance. CVSIC’s comprehensive maintenance kits and guidance significantly streamline the process, supporting sustained reliability.

Are gas costs significant for atmospheric furnaces?

Costs vary depending on the experiment frequency and the type of gas used. High-purity argon can be expensive, but CVSIC’s furnaces optimize gas efficiency to minimize expenses.