FeCrAl Alloy Comparison and Selection Guide

From our earlier guides on FeCrAl fundamentals and the seven primary grades, you already understand: This article delivers a clear,…

From our earlier guides on FeCrAl fundamentals and the seven primary grades, you already understand: This article delivers a clear,…

Ethan

Product catalogs often list a dozen FeCrAl grades: 0Cr23Al5, 0Cr25Al5, 0Cr21Al6, 0Cr27Al7Mo2, 0Cr21Al6Nb, and more. The real questions are: Memorizing…

Ethan

In real industrial electric heating setups, FeCrAl isn’t “the safe bet”—it’s actually one of the most misunderstood and misused materials…

Ethan

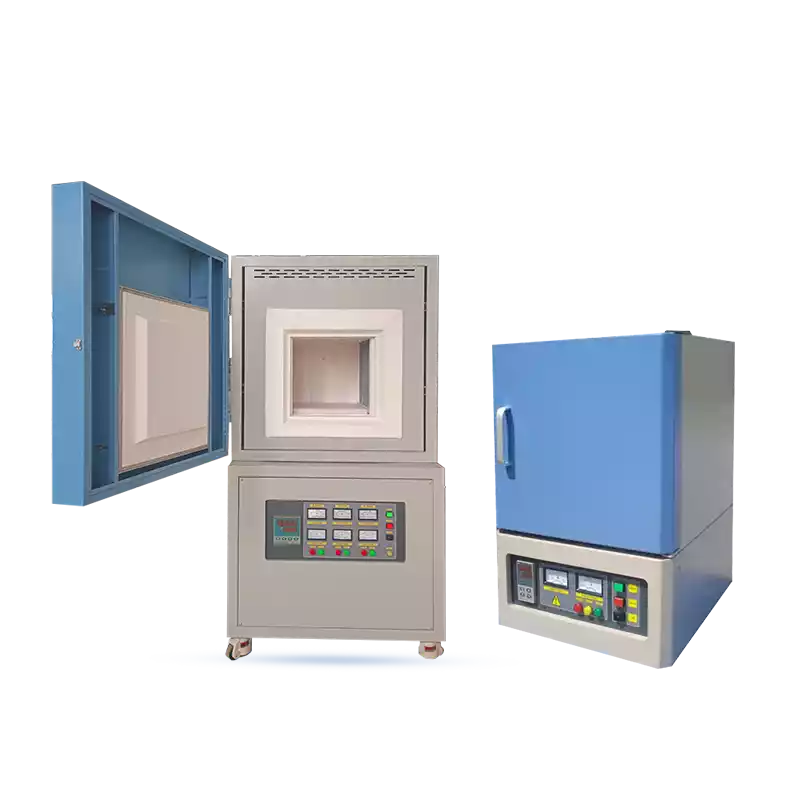

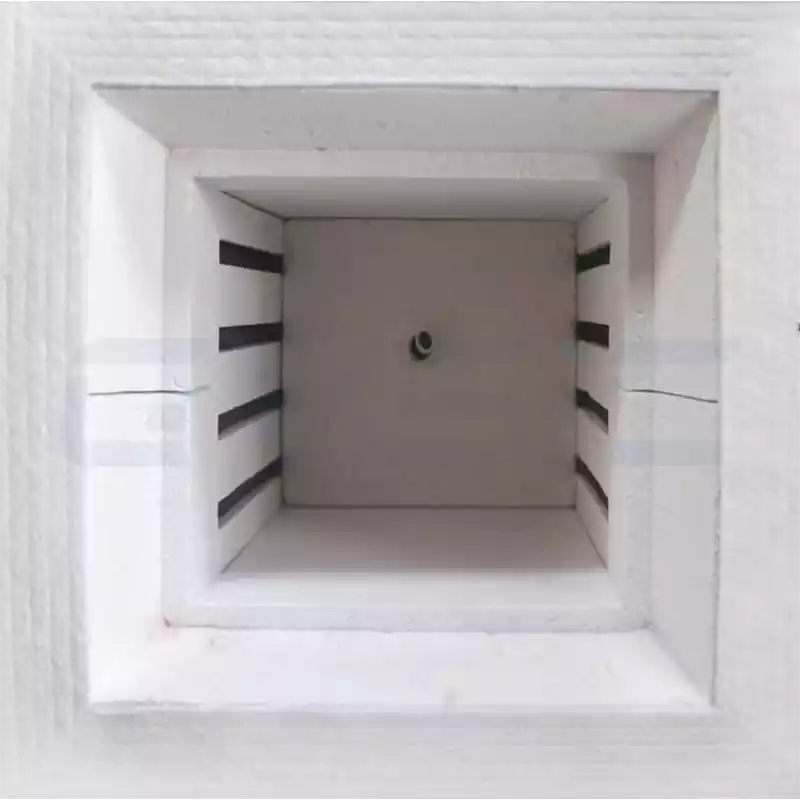

Signs of Uneven Heating and Slow Temperature Rise In lab or industrial settings, muffle furnace users often face these telltale…

Ethan

For many procurement engineers, “How to pick a ceramic fiber board?” seems like a straightforward question, but when it hits…

Ethan

Routine maintenance and cleaning are vital for ensuring the longevity of your muffle furnace and the success of your experiments.…

Ethan

Ceramic fiber materials aren’t “new materials” anymore; they’ve become the go-to lightweight refractory materials in industries like metallurgy, heat treatment,…

Ethan

Heating elements power the heart of any muffle furnace, much like an engine drives a vehicle—dictating efficiency and longevity. From…

Ethan

In research labs and production lines, muffle furnace temperature uniformity is non-negotiable. From ceramic sintering and metal heat treatment to…

Ethan

PID stands for Proportional-Integral-Derivative control—a proven, precise thermal management algorithm. In muffle furnaces, PID controllers continuously adjust heating power to…

Ethan

Selecting a muffle furnace primarily depends on the heating element, which influences maximum temperature, longevity, efficiency, and outcomes. Common heating…

Ethan

In materials research and high-temperature testing, a 1800°C muffle furnace embodies peak heating performance. Beyond 1700°C, many standard materials reach…

Ethan

In high-temperature materials testing or industrial heat treatment, CVSIC engineers often field this question:”Should I go with a 1400°C muffle…

Ethan

In high-temperature engineering, heating elements are the “heart” of furnace and kiln systems—their durability impacts uptime, energy efficiency, and operating…

Ethan

The 1100°C muffle furnace is an essential tool for laboratories and the light industry, excelling at material pretreatment, ash determination,…

Ethan