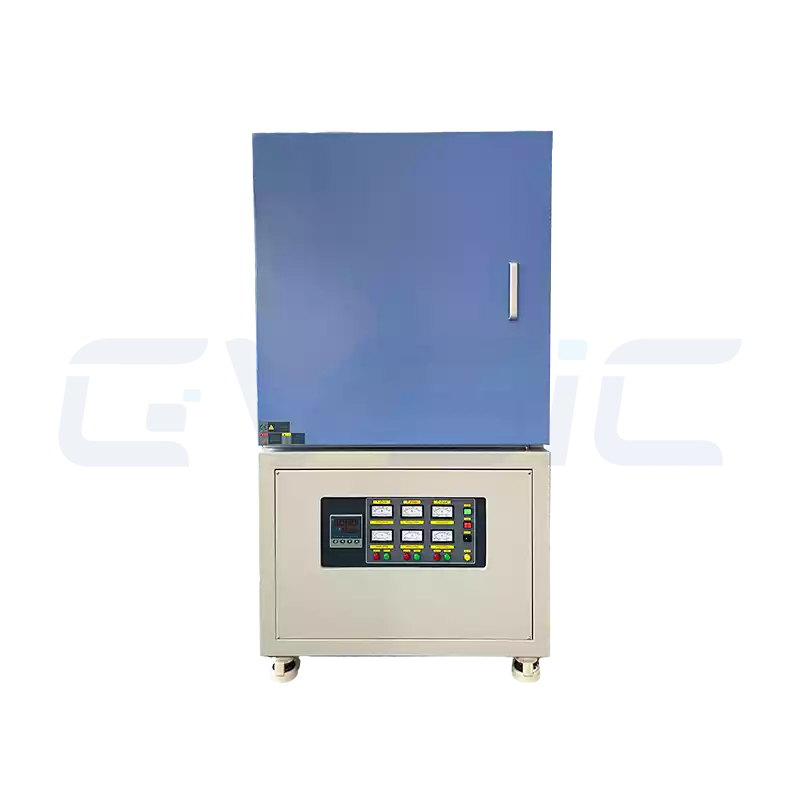

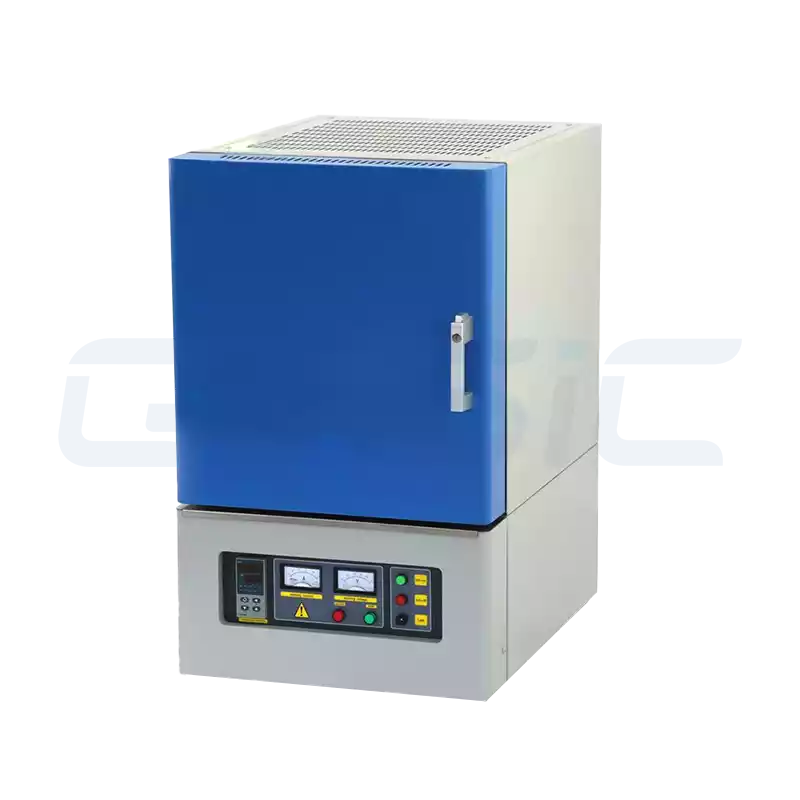

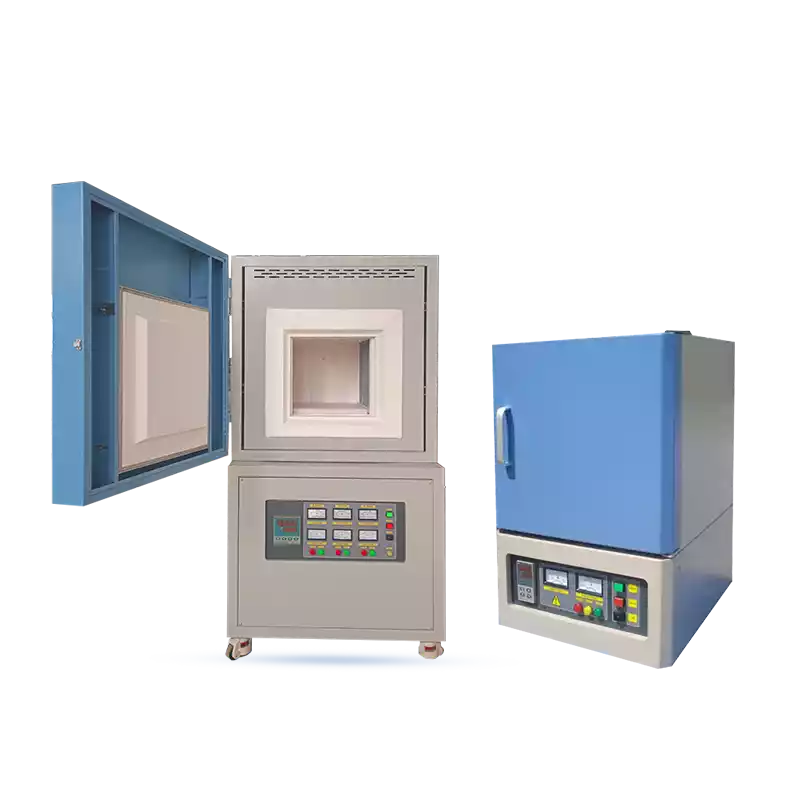

In high-temperature materials testing or industrial heat treatment, CVSIC engineers often field this question:”Should I go with a 1400°C muffle furnace or a 1700°C one?”

While the 300°C difference may seem modest at first glance, this gap drives profound differences in heating elements, insulation, processing capabilities, and cost structures, which become apparent as you compare each model in detail.

We’ll dissect both models to help you choose your ideal “high-heat ally.” At CVSIC, we prioritize precision engineering and seamless user experiences.

Core Differences: 1400°C vs. 1700°C Muffle Furnaces

These furnaces differ in heating elements, temperature capabilities, material compatibility, applications, and maintenance. Here’s a side-by-side, drawing on CVSIC expertise and addressing your challenges.

Heating Elements: SiC vs. MoSi2

- 1400°C Muffle Furnace: Relies on silicon carbide (SiC) elements for rapid ramp-up and high efficiency in the 1200–1400°C range. Ideal for mid-high temperature work, though oxidation in prolonged heat or humidity can limit lifespan to 2000–5000 hours.

- 1700°C Muffle Furnace: Employs molybdenum disilicide (MoSi₂) elements with superior oxidation resistance for steady performance at 1600–1700°C and beyond. Expect 3000–8000 hours of service life, but handle with care due to material brittleness during setup and upkeep.

Insight: SiC forms a SiO₂ protective layer under heat, yet extended exposure may hike resistance. MoSi₂’s layer holds up better, excelling in extreme conditions.

Quick Comparison Table

| Aspect | 1400°C Muffle Furnace | 1700°C Muffle Furnace |

| Heating Element | Silicon Carbide (SiC) | Molybdenum Disilicide (MoSi₂) |

| Max Operating Temp | ≤1400°C (Sustained ≤1350°C) | ≤1700°C (Sustained ≤1650°C) |

| Key Features | Affordable, simple build, fast heat-up | High-temp stability, long life, strong oxidation resistance |

| Ideal Applications | Ceramics, glass, powder metallurgy pre-sintering | High-purity ceramics, oxide sintering, crystal growth |

Chamber Materials: Lightweight Ceramics vs. High-Purity Alumina Fiber

Extreme heat demands more than robust elements—it calls for chambers with tailored thermal stability, shock resistance, and insulation.

| Aspect | 1400°C Chamber | 1700°C Chamber |

| Material | High-Alumina Fiber + SiC Board | High-Purity Alumina or Mullite Fiber |

| Max Temp Limit | 1450°C | 1800°C |

| Thermal Conductivity | Moderate | Lower (Better Energy Efficiency) |

| Thermal Shock Resistance | Good | Excellent |

The 1700°C model’s alumina fiber lining offers enhanced reflectivity and corrosion resistance, ensuring structural integrity under heat—resistant deformation or degradation.

Temperature Ranges and Applications

1400°C Muffle Furnace

Key Experiments: Ceramic sintering, metal annealing, powder metallurgy, and catalyst calcination. A strong fit for mid-range needs, like alumina sintering (1300–1400°C) or stainless steel treatments.

- Compatible Materials: Mid-to-low melt ceramics (e.g., alumina, zirconia), low-carbon steel, stainless steel, select composites.

- Strengths: Handles most lab and small-scale industrial tasks with excellent value.

- Limitations: Not suited for high-temp ceramics (e.g., silica) or glass melting (1600°C+ required).

1700°C Muffle Furnace

Key Experiments: High-temp ceramic sintering, glass melting, specialty alloy treatments, and advanced material testing. Perfect for cutting-edge R&D or production, such as zirconia densification or glass forming.

- Compatible Materials: High-melt ceramics (e.g., zirconia, silicon nitride), glass, titanium alloys, ultra-high-temp composites.

- Strengths: Enables extreme-heat processes with precision for demanding research.

- Limitations: Premium pricing makes it best for well-funded setups with stringent temp specs.

User Tip: If your lab needs to minimize costs, select CVSIC’s 1400°C models. For advanced research or industrial processes, 1700°C models are a better match. Still unsure? Review the comparison table or contact us for guidance.

| Application Area | 1400°C Muffle Furnace | 1700°C Muffle Furnace |

| Standard Ceramic Pre-Sintering | Viable | Superior |

| High-Purity Alumina/Zirconia Sintering | Limited | Recommended |

| Glass Annealing/Glaze Testing | Suitable | Suitable |

| Powder Metallurgy/Alloy Sintering | Applicable | Enhanced High-Temp Performance |

| Crystal Materials/Oxide Research | Limited | Specialized |

| Research Institutions/Labs | Standard Setup | Premium Experimental |

Control Systems and Performance

| Feature | 1400°C | 1700°C |

| Temp Control | Smart PID | Smart PID + Fuzzy Logic |

| Uniformity | ±5°C | ±3°C |

| Ramp Rate | 10–20°C/min | 10–30°C/min |

| Energy Use | Lower | Slightly Higher |

| Lifespan & Maintenance | Moderate Element Life | Longer Life, Higher Cost |

CVSIC equips both with premium imported modules and K-type/S-type thermocouples for enduring reliability.

Costs and Maintenance

| Aspect | 1400°C Muffle Furnace | 1700°C Muffle Furnace |

| Purchase Cost | Budget-Friendly | Premium |

| Maintenance Cost | Low (Easy Element Swap) | Higher (Costly Components) |

| Service Life | ~2–3 Years | ~3–5 Years |

| Ideal Users | Teaching Labs, Material Testing | R&D Institutes, High-End Manufacturing, Sintering Facilities |

Economically, the 1400°C is pragmatic; performance-wise, the 1700°C is unparalleled. Your pick hinges on goals versus budget.

Selection Framework: 1400°C or 1700°C?

The right choice boils down to your priorities. Here’s a streamlined decision guide:

- Temp Needs: 1200–1400°C? Go 1400°C (SiC). Over 1500°C? Essential to select 1700°C (MoSi₂).

- Material Type: Mid-low melts favor 1400°C; high-melt ceramics or glass demand 1700°C.

- Budget: 1400°C offers value for startups or routine work; 1700°C fits advanced R&D or industry.

- Maintenance: 1400°C keeps costs down; 1700°C requires expert oversight.

In Summary: Tailor Your High-Temp Solution

1400°C and 1700°C muffle furnaces fit different needs, not better or worse.

CVSIC offers 1100–1800°C box furnaces for research, materials, metallurgy, electronics, ceramics, and more, including OEM/ODM and custom options.

Choose CVSIC as your informed heat management partner.

FAQ

Can a 1700°C muffle furnace substitute for a 1400°C one?

Yes, but sustained low-temp runs accelerate MoSi₂ oxidation—inefficient for the long haul.

Can a 1400°C furnace push to 1500°C temporarily?

Not advisable. Overloading risks rapid SiC degradation or failure.

Does the 1700°C model ramp faster?

Comparable rates, but MoSi₂’s resilience supports higher power densities for demanding profiles.

Which is more energy-efficient?

1400°C uses less power overall, yet the 1700°C’s superior insulation yields better efficiency in extended high-heat operations.