Having worked in the high-temperature industrial sector for many years, I fully understand how heavily powder metallurgy (PM) relies on atmosphere furnaces. Whether producing cemented carbide tools, stainless steel components, or high-performance magnetic materials, atmosphere furnaces serve as the “unsung heroes” ensuring product quality and enabling process success. Yet many customers often wonder: What role do atmosphere furnaces play in the powder metallurgy process? How should specific process details be controlled? How can efficiency be improved? What are typical applications? Today, CVSIC presents a comprehensive guide to help you understand the core value and typical processes of atmosphere furnaces in powder metallurgy, enabling precise production optimization!

The Role of Atmosphere Furnaces in Powder Metallurgy

The core process of powder metallurgy involves compressing metal powders into shapes and then sintering them at high temperatures to form dense components. Throughout this process, atmosphere furnaces provide specific protective gas environments (such as hydrogen, nitrogen, or mixed atmospheres), fulfilling four critical functions:

Preventing Oxidation

Metal powders readily react with oxygen at high temperatures, leading to performance degradation or even part failure. Atmosphere furnaces completely isolate oxygen by introducing inert gases (e.g., nitrogen, argon) or reducing gases (e.g., hydrogen), ensuring purity on both the surface and interior of workpieces.

Promoting Sintering

Sintering is the core process in powder metallurgy. By precisely controlling temperature and atmosphere, the furnace effectively promotes bonding between powder particles, enhancing part strength and density. For instance, hydrogen removes residual oxides from powder surfaces, strengthening particle adhesion.

Optimizing Material Properties

Specific atmospheres can alter a material’s microstructure and chemical composition. For instance, carburizing atmospheres significantly increase surface hardness, while mixed atmospheres optimize magnetic properties in magnetic materials.

Improving Yield Rates

Stable atmosphere control and temperature management reduce defects (such as porosity and cracks), enhancing product quality. CVSIC’s atmosphere furnaces, equipped with high-precision PLC systems, ensure atmosphere fluctuations remain within 1%, significantly boosting yield rates.

Typical Processes: Applications of Atmosphere Furnaces in Powder Metallurgy

Powder metallurgy encompasses multiple specialized processes where atmosphere furnaces play an indispensable role. Below are four typical processes and their requirements for atmosphere furnaces:

Sintering Process

Function: Promotes dense bonding of powder particles through high-temperature environments, forming high-strength, high-density finished components.

Atmosphere Selection:

- Hydrogen: Used for sintering materials like cemented carbides (e.g., WC-Co) or stainless steel. Effectively removes powder oxides and enhances particle bonding.

- Nitrogen: An economical choice suitable for iron-based parts or materials with low oxidation sensitivity.

- Mixed Atmosphere (e.g., N₂+H₂): Balances reducing properties and cost advantages, widely used for sintering complex alloys.

Temperature Range: 1000-1500°C, adjusted based on material properties.

CVSIC Advantage: Our atmosphere furnace supports multi-zone independent temperature control with ±3°C precision, ensuring uniformity throughout the chamber.

Reduction Process

Function: Removes oxides adhering to metal powder surfaces, restoring metal purity and enhancing final part performance.

Atmosphere Selection: Pure hydrogen or hydrogen-nitrogen mixtures, with hydrogen proportion adjustable (typically 10-100%).

Typical Applications: Pre-treatment reduction of copper-based and iron-based powders, or purity enhancement of magnetic materials (e.g., NdFeB).

CVSIC Tip: Our atmosphere furnaces feature high-precision gas flow control, enabling real-time, accurate hydrogen concentration adjustment for safe and efficient operation.

Carburizing Process

Function: Significantly enhances surface hardness and wear resistance by introducing carbon sources (e.g., methane) into the atmosphere.

Atmosphere Selection: Carbon-containing gases (e.g., methane + nitrogen) or customized mixed atmospheres.

Typical Applications: Automotive gears, bearings, and other components requiring extremely high surface hardness.

CVSIC Advantage: Our atmosphere furnaces enable precise control of complex gas mixtures, with carburization depth accurately controlled to 0.1mm.

Annealing and Heat Treatment

- Function: Effectively eliminates internal stresses and optimizes mechanical properties by precisely controlling the entire heating, soaking, and cooling process.

- Atmosphere Selection: Nitrogen or argon prevents oxidation; hydrogen is used for reduction annealing of specific alloys.

- Typical Applications: Annealing processes for stainless steel parts, tool steel, etc.

- CVSIC Tip: Our furnaces support programmable temperature profiles, eliminating manual adjustments for complex heat treatment requirements.

Selection Recommendations: Choosing the Right Atmosphere Furnace for Powder Metallurgy

When selecting an atmosphere furnace, prioritize the following five factors based on specific powder metallurgy requirements:

Furnace Type:

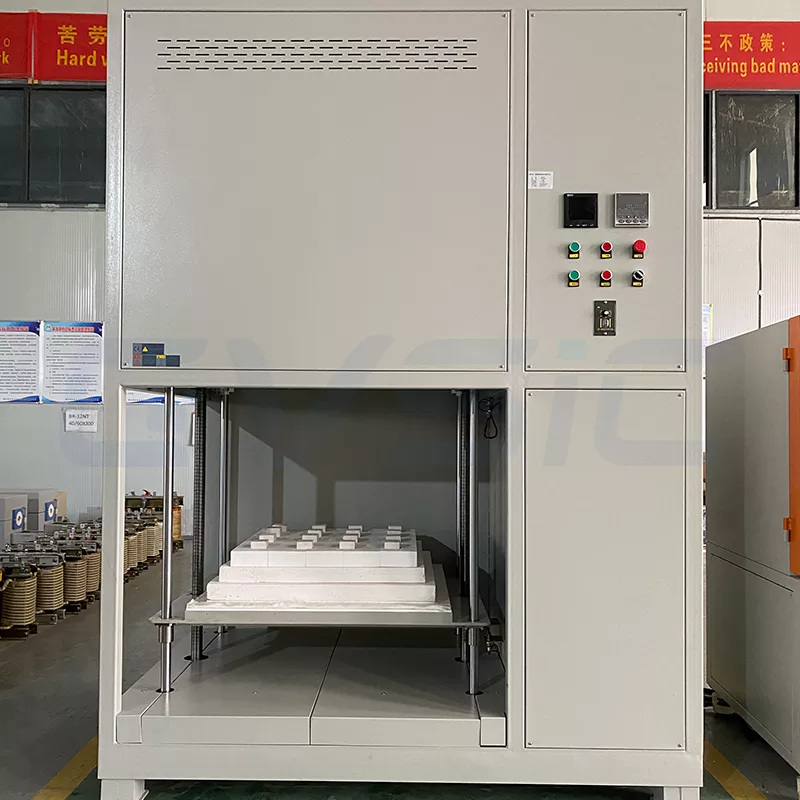

- Small-batch production or R&D scenarios: Box or tube-type atmosphere furnaces offer flexibility and lower costs.

- High-volume industrial production: Continuous atmosphere furnaces deliver high efficiency for industrial scale.

Temperature Range:

Ensure the furnace’s maximum temperature covers the sintering requirements of target materials (e.g., cemented carbides require 1300-1500°C).

Atmosphere Control:

Prioritize furnaces supporting rapid multi-gas switching and high-precision atmosphere concentration control to meet requirements for hydrogen, nitrogen, etc.

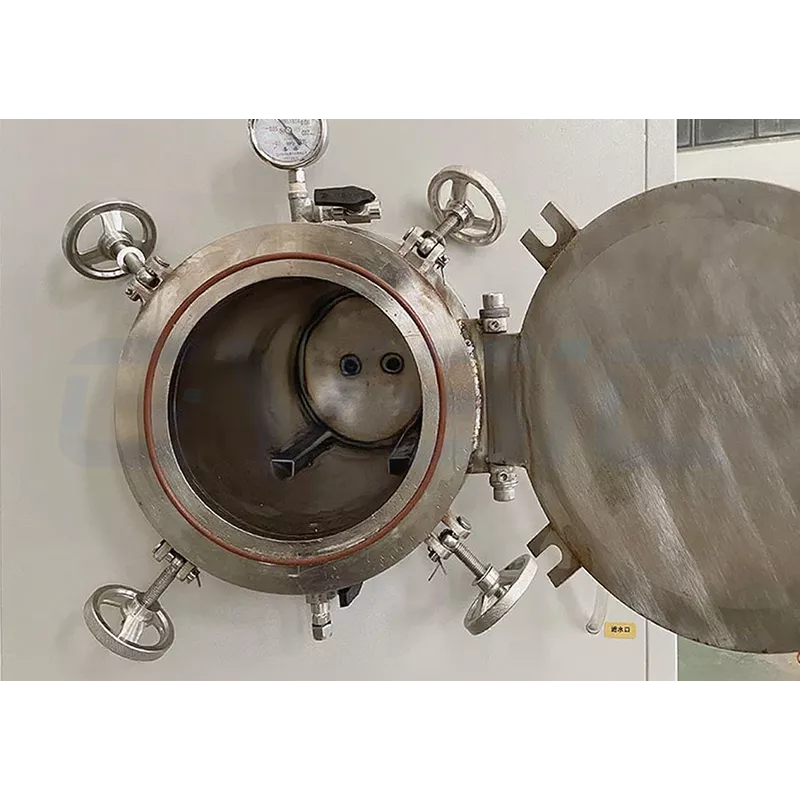

Safety:

When using hydrogen, ensure furnaces are equipped with safety systems like gas leak detection and automatic shut-off valves.

Energy Efficiency & Cost:

Prioritize energy-efficient atmosphere furnaces to reduce electricity consumption and gas costs.

CVSIC Advantages:

CVSIC atmosphere furnaces are specifically optimized for powder metallurgy processes, maintaining temperature uniformity within ±3°C and achieving industry-leading precision in gas concentration control, all with multiple safety protections. Our continuous atmosphere furnaces boost production efficiency by 30%, enabling effortless handling of large-scale manufacturing. Chamber furnaces are ideal for laboratory R&D, enabling seamless transition from development to production.

Why Choose CVSIC?

At CVSIC, we are more than equipment suppliers—we are your partners in process optimization. With over 20 years of industry expertise, we have a deep understanding of the challenges in powder metallurgy. Our furnaces are designed and manufactured with customer needs at the core. Whether for laboratory pilot furnaces or factory-scale production lines, CVSIC delivers more efficient, safer, and cost-effective solutions.

Struggling with powder metallurgy processes? Contact our engineering team now for a free technical consultation and receive your customized atmosphere furnace solution today!

FAQ

How do atmosphere furnaces improve powder metallurgy yield rates?

By supplying protective gases (e.g., hydrogen, nitrogen) to prevent part oxidation and precisely controlling temperature and atmosphere concentration, defects like porosity and cracks are minimized. CVSIC’s atmosphere furnaces can elevate yield rates to over 95%.

Is hydrogen safe in powder metallurgy?

CVSIC atmosphere furnaces are equipped with gas leak detection systems, automatic shut-off valves, and pressure relief valves to ensure safe operation of hydrogen.

What atmosphere is best for sintering cemented carbides?

Prioritize pure hydrogen or hydrogen-nitrogen mixtures to effectively remove surface oxides from carbide powders. CVSIC enables precise gas concentration ratios to enhance sintering quality.

Are atmosphere furnaces suitable for large-scale powder metallurgy production?

Absolutely! CVSIC’s continuous atmosphere furnaces are engineered for high-volume scenarios, meeting mass production demands for automotive components, cutting tools, and more.

Can CVSIC customize furnaces for specialized powder metallurgy processes?

Certainly! CVSIC offers comprehensive customization from furnace chamber design to atmosphere control. Simply share your process details, and we’ll deliver a tailored solution. Feel free to reach out anytime!