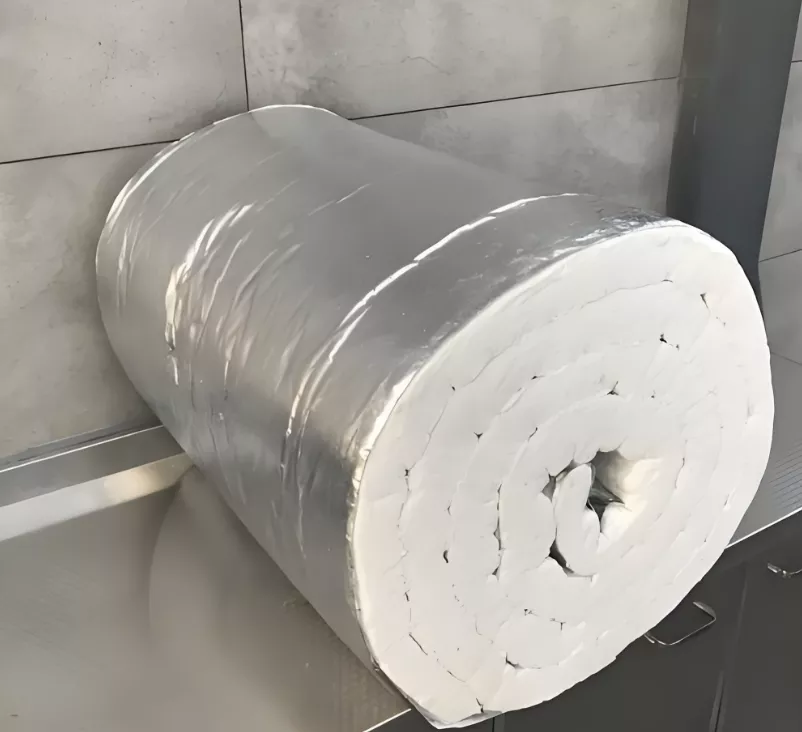

Installing and maintaining ceramic fibre blankets is like putting ‘protective armour’ on equipment. Proper installation and maintenance maximise insulation performance and extend equipment life.

As China’s leader in industrial heating, CVSIC knows proper operation is crucial. This article explains the step-by-step installation and maintenance of ceramic fibre blankets to help maximise their effectiveness.

Steps for Installing Ceramic Fibre Blankets

Proper installation is essential for insulation, fireproofing, and sound reduction. CVSIC’s steps are easy to follow for most industrial applications:

- Safety precautions: Wear a dust mask, gloves, and protective clothing to avoid inhaling fibres or skin irritation.

- Tool preparation: Prepare cutting knives, high-temperature adhesive, fixing nails, metal mesh, measuring tape, and sealing materials.

- Environmental inspection: Ensure the construction surface is clean, flat, and free of oil or moisture to ensure proper blanket adhesion.

Precise measurement and cutting

- Measure dimensions: Use a measuring tape to measure the dimensions of the equipment or pipes, recording length, width, and thickness requirements.

- Use a sharp knife to cut straight lines, leaving a 1–2 cm allowance. For complex shapes, use a template to pre-cut.

Notes: Maintain fibre integrity during cutting to avoid structural loosening caused by pulling.

Fixing and Adhesion

- Fixing methods: Select the fixing method based on the equipment type:

- Flat surfaces (e.g., furnace walls): Apply high-temperature adhesive evenly, press the blanket firmly into place, or secure with ceramic fixing nails.

- Wrap the blanket around pipes or equipment and secure with metal mesh or high-temperature tape to keep it tight.

- Seamless adhesion: Ensure the blanket is in close contact with the surface, with no wrinkles or gaps. Seam areas should be treated with high-temperature sealant to prevent heat leakage.

- For ultra-high temperatures (above 1400°C), stack 2–3 layers (25–50 mm) of CV1430 or CV1600 to boost insulation.

- Layering technique: Offset the seams of each layer, similar to bricklaying, to prevent direct heat transfer. Use fixing nails to secure each layer, ensuring stability.Layering reduces conductivity (from 0.21 W/m·K at 800°C) and saves 10-15% energy.

Post-installation inspection

- Inspection points: Ensure the blanket is secure with no gaps or curled edges, fixing nails are secure, and seams are fully sealed.

- Performance testing: Start the equipment and observe temperature distribution to confirm insulation effectiveness.

- Record keeping: Record installation date, model, and thickness for future maintenance tracking.

Installation tips:

For initial installation, contact the CVSIC technical team for on-site guidance or remote support!

Maintenance Tips for Ceramic Fibre Blankets

CVSIC ceramic fibre blankets are durable, but regular maintenance can enhance their performance and extend their lifespan. Here is a maintenance checklist:

1. Regular Wear Inspection

- Frequency: Inspect every 3–6 months, focusing on high-temperature areas (e.g., furnace inlet).

- Inspection items: Check the blanket surface for cracks, wear, or fibre shedding. CV1600 (linear shrinkage rate ≤1.0% at 1500°C) is particularly suitable for long-term high-temperature use with low wear rates.

- For small wear, use repair adhesive; for severe wear, replace the affected blanket. Contact us for fast replacement.

2. Prevent liquid penetration

- Risk: Moisture or oil contamination can reduce insulation performance and even cause fibre structure damage.

- Keep equipment surfaces dry before installation and avoid liquid splashes. Use waterproof coatings for hot pipes.

- CVSIC recommendation: Regularly inspect the condition of the sealant and reapply as necessary to keep the blanket dry.

3. Storage precautions

- Storage environment: Unused Ceramic Fire Blanket should be stored in a dry, well-ventilated warehouse to avoid moisture or heavy object compression.

- Packaging protection: Use CVSIC original cardboard boxes or woven bags to prevent fibre damage.

- Store blankets in a dry, well-ventilated area and use them within a year for optimal results. Need long-term storage? Ask CVSIC for advice.

4. Safety and Environmental Protection Maintenance

- Safety precautions: Wear a mask and gloves during maintenance to avoid inhaling fibres or skin contact.

- Disposal: Dispose of used blankets in accordance with local environmental regulations. CVSIC provides environmental recycling guidelines to ensure compliance.

- CVSIC Support: Our blankets are ISO 9001 certified with low fibre shedding rates, ensuring safety and environmental protection for peace of mind!

Maintenance Reference Data

| Maintenance Task | Frequency | Recommended Tools/Materials | Benefit |

| Wear Inspection | Every 3–6 months | Flashlight, repair agent | Extends lifespan by 20–30% |

| Sealant Inspection | Every 6 months | High-temperature sealant | Reduces heat loss by 10% |

| Liquid Protection | Continuous during operation | Waterproof coating | Maintains insulation performance |

Frequently Asked Questions

Does installing ceramic fibre blankets require a professional team?

Not necessarily! CVSIC blankets are easy to cut and install; simply follow our tutorial to get started. For complex projects, contact CVSIC for on-site support!

How can I avoid installation gaps affecting insulation?

Use CVSIC sealant to treat joints, offset joints when layering multiple layers, and ensure seamless adhesion. Our engineers can provide precise advice!

Are maintenance costs high?

No. CVSIC ceramic fiber blankets are durable. Regular inspections and minimal repairs keep maintenance affordable. Download our manual for tips.

Conclusion

Proper installation and maintenance enhance the efficiency and durability of industrial furnaces. CVSIC products and accessories provide top insulation, fire resistance, and noise reduction. For installation or maintenance, CVSIC provides support with tutorials, technical assistance, and customized services.