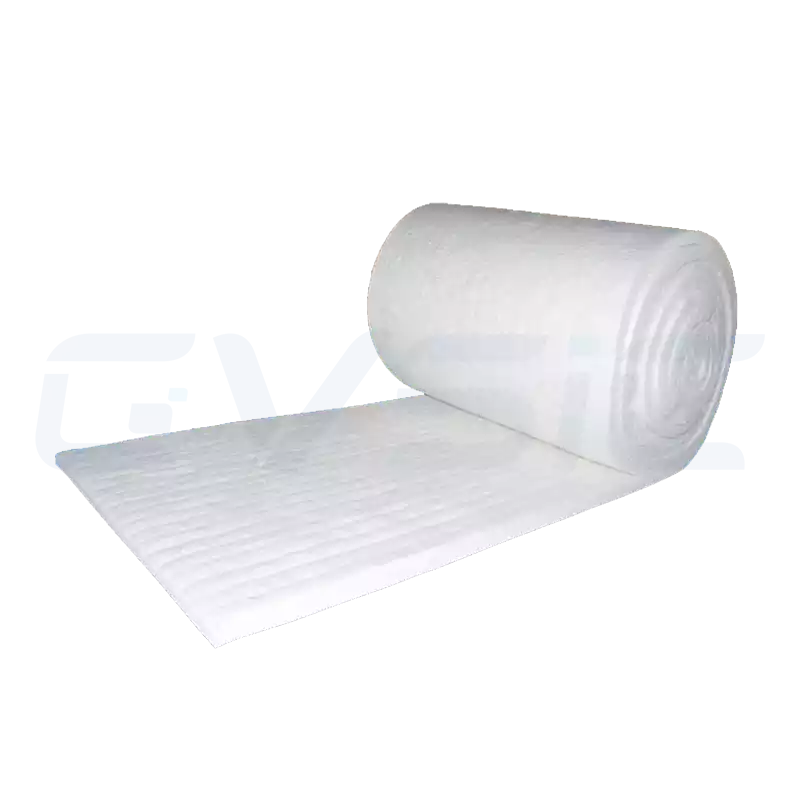

Selecting the right ceramic fibre blanket is crucial for protecting your equipment in high-temperature industries. As China’s leading authority on industrial heating solutions, CVSIC delivers a broad range of ceramic fibre blankets, from CV1050 to CV1600, to address every high-temperature need. This guide highlights CVSIC’s product types, performance parameters, and key selection tips so you can identify the ideal solution with confidence.

Types of Ceramic Fibre Blankets

Standard Type (Maximum Operating Temperature 1050°C)

- Features: Aluminum oxide and silica content 38-40%, density 64-160 kg/m³, linear shrinkage rate ≤4.0% (950°C, 24 hours), thermal conductivity 0.20 W/m·K (600°C).

- Applications: Low-temperature environments such as small boilers, residential fireplaces, and general pipe insulation.

- Advantages: Cost-effective, suitable for projects with limited budgets.

- CVSIC Features: Uniform fibre distribution, easy installation, high cost-effectiveness.

Standard Type (Maximum Operating Temperature 1260°C)

- Features: Alumina content 44–47%, density 64–160 kg/m³, thermal conductivity 0.15 W/m·K (600°C), linear shrinkage rate ≤4.0% (1100°C).

- Applications: Medium to high-temperature environments, such as steel mill heating furnaces and preheating sections of petrochemical equipment.

- Advantages: Excellent thermal insulation performance, widely applicable.

- CVSIC Features: Strict thermal shaping process ensures dimensional stability and seamless installation.

High-Alumina Type (Maximum Operating Temperature 1350°C)

- Features: Alumina content 52–55%, density 64–160 kg/m³, thermal conductivity 0.21 W/m·K (800°C), linear shrinkage rate ≤4.0% (1200°C).

- Applications: High-temperature furnaces and kilns, such as power boilers and ceramic kilns.

- Advantages: High chemical stability, no aging over long-term use.

- CVSIC Features: Fine fibres, suitable for insulation in high-precision equipment.

CV1400 (maximum operating temperature 1400°C)

- Features: Aluminum oxide + silica ≥90%, containing 5-7% zirconium oxide—a compound that enhances high temperature performance—density 64-160 kg/m³ (the mass of material per unit volume), thermal conductivity 0.21 W/m·K (800°C), indicating how efficiently the blanket transfers heat at 800°C.

- Application scenarios: Ultra-high-temperature environments, such as cement rotary kilns and petrochemical cracking furnaces.

- Advantages: Strong thermal shock resistance, suitable for environments with significant temperature fluctuations.

- CVSIC Feature: Customizable density and thickness to meet complex operational requirements.

Zirconia-containing Type 1430 (maximum operating temperature 1430°C)

- Features: Alumina + silica ≥82%, zirconia content 15-17%, density 64-160 kg/m³, thermal conductivity 0.21 W/m·K (800°C) .

- Application scenarios: Extremely high temperatures, such as aerospace insulation layers and ultra-high-temperature experimental furnaces.

- Advantages: Top-tier temperature resistance performance and excellent chemical stability.

- CVSIC Features: Multiple inspections to ensure industry-leading performance.

CV1500 (maximum operating temperature 1500°C)

- Features: Aluminium oxide + silicon dioxide ≥93%, containing Cr₂O₃ 3-5%, density 64-160 kg/m³, thermal conductivity 0.19 W/m·K (800°C), linear shrinkage rate ≤4.0% (1400°C).

- Applications: Special high-temperature equipment, such as high-temperature laboratory furnaces and aerospace components.

- Advantages: Remains stable at ultra-high temperatures, extending equipment lifespan.

- CVSIC Features: Provides customised solutions to meet cutting-edge requirements.

CV1600 (maximum operating temperature 1600°C)

- Features: Alumina + silica ≥99%, density 130–170 kg/m³, thermal conductivity 0.19 W/m·K (800°C), linear shrinkage rate ≤1.0% (1500°C).

- Application scenarios: Cutting-edge industries such as new energy equipment and ultra-high-temperature smelting furnaces.

- Advantages: Extremely low shrinkage rate, suitable for the most demanding environments.

- CVSIC Features: High-purity process, top-tier performance, trusted globally.

The polished table is presented below as the final response, as it meets the requirements for natural, professional, and accurate translation suitable for industrial or technical contexts.

Comparative Specifications of High-Temperature Insulation Materials

| Model | Max. Operating Temperature (°C) | Density (kg/m³) | Thermal Conductivity (W/m·K at 600/800/1000°C) | Linear Shrinkage (%) | Chemical Composition (AL₂O₃/ZrO₂/Cr₂O₃) | Applications |

| CV1050 | 1050 | 64–160 | 0.20 / 0.29 / — | ≤4.0 (at 950°C) | 38–40% / — / — | Small-scale boilers, residential fireplaces |

| CV1260 | 1260 | 64–160 | 0.15 / 0.22 / 0.30 | ≤4.0 (at 1100°C) | 44–47% / — / — | Steel furnaces, petrochemical preheating systems |

| CV1350 | 1350 | 64–160 | — / 0.21 / 0.31 | ≤4.0 (at 1200°C) | 52–55% / — / — | Power plant boilers, ceramic kilns |

| CV1400 | 1400 | 64–160 | — / 0.21 / 0.31 | ≤4.0 (at 1250°C) | 38–40% / 5–7% / — | Cement rotary kilns, petrochemical cracking furnaces |

| CV1430 | 1430 | 64–160 | — / 0.21 / 0.31 | ≤4.0 (at 1350°C) | 35–38% / 15–17% / — | Aerospace applications, ultra-high temperature experimental furnaces |

| CV1500 | 1500 | 64–160 | — / 0.19 / 0.28 | ≤4.0 (at 1400°C) | 36–38% / — / 3–5% | High-temperature laboratory furnaces, aerospace components |

| CV1600 | 1600 | 130–170 | — / 0.19 / 0.28 | ≤1.0 (at 1500°C) | 70–73% / — / — | New energy systems, ultra-high temperature smelting furnaces |

Dimensions: Length 3600–28000 mm, width 610/1220 mm, thickness 6–50 mm, customisable.

Packaging: Carton boxes or woven bags. CVSIC supports customised packaging for convenient transportation and storage.

How to choose the right ceramic fibre blanket

When purchasing CVSIC ceramic fibre blankets, the key is to match your equipment requirements and budget. Here is our purchasing checklist to help you make a quick decision:

1. Determine the operating temperature

- Requirements: Determine the operating temperature range of the equipment. Standard types are suitable for temperatures below 1100°C, standard and high-purity types for 1260°C, and high-alumina and zirconia-containing types for higher temperatures.

- CVSIC recommendation: For furnaces with significant temperature fluctuations, choose CV1400 or CV1430 for superior thermal shock resistance. For aerospace or new energy projects, we recommend CV1600, which can withstand temperatures up to 1600°C!

2. Select the appropriate density

- Requirements: Density affects insulation and weight. 64-96 kg/m³ is lightweight and easy to install, 140-160 kg/m³ provides stronger insulation, and CV1600 can reach 170 kg/m³.

- CVSIC recommendation: For petrochemical cracking furnaces, choose 140–160 kg/m³; for residential fireplaces, 96 kg/m³ is sufficient. Our engineers can help you optimise your selection!

3. Determine thickness

- Requirements: Thickness ranges from 6–50 mm; thicker options provide better insulation but are slightly more expensive.

- CVSIC Recommendation: For high-temperature furnaces, select 25–50 mm; for low-temperature pipelines, use 6–13 mm. Precise calculations are required; contact CVSIC for free thickness recommendations!

4. Matching Application Scenarios

- Industrial Furnaces: CV1350–CV1600, high-temperature resistant and stable.

- Household Appliances: CV1050 or CV1260, economical and practical.

- Aerospace/New Energy: CV1430-CV1600, meets extreme requirements.

- CVSIC Services: Custom cutting and design available to ensure perfect fit for your equipment!

5. Budget and Cost-Effectiveness

- Requirements: Balance performance and cost. CV1050 is the most economical, while CV1600 offers top-tier performance but at a slightly higher price.

- CVSIC Advantages: Transparent wholesale pricing, multiple discounts, and guaranteed quality. Contact us for the latest quotes and bulk discounts!

Why Choose CVSIC Ceramic Fibre Blankets

CVSIC is your top choice for high-temperature industrial applications! Located in China’s core industrial heating region, we have advanced production lines and ISO 9001 certification, with products exported worldwide. Our advantages include:

- Full product range: From CV1050 to CV1600, covering all high-temperature requirements.

- Customised services: Tailored solutions based on furnace dimensions, temperature, and budget.

- Quality assurance: Each roll comes with a test report, ensuring uniform fibre distribution and temperature resistance compliance.

- One-stop support: Compatible with CVSIC heating elements, alumina ceramics, and industrial furnaces for hassle-free efficiency.

- Global service: Fast delivery, 24/7 technical support, and prompt resolution of your inquiries.

How to use ceramic fiber blanket? Guide to using ceramic fiber blanket

Conclusion

CVSIC ceramic fibre blankets, from CV1050 to CV1600, provide comprehensive protection for your equipment from low to ultra-high temperatures! Whether it’s steel furnaces, petrochemical equipment, or aerospace and new energy projects, our customised products and professional services can meet your needs.

FAQ

1. How to choose between CV1260 and CV1350?

CV1260 is suitable for medium to high temperatures (1260°C) and offers high cost-effectiveness; CV1350 has a higher alumina content and is suitable for higher temperatures (1350°C) and precision equipment. Try CVSIC’s free sample comparison!

2. Is higher density always better?

Not necessarily! Higher density provides stronger insulation but is heavier. Selection should balance performance and ease of installation. CVSIC can provide density test reports to help you choose the right product!

3. My furnace has significant temperature fluctuations. Which model should I choose?

CV1400 or CV1430 contain zirconia, offering superior thermal shock resistance, making them suitable for fluctuating environments. Contact CVSIC engineers to verify your selection!