Introduction: Why Does MIM Demand Specific Debinding Furnaces?

Metal Injection Molding (MIM) is a high-precision, high-efficiency manufacturing process widely used for producing components for mobile phones, automotive precision parts, medical devices, and other applications. A critical step in MIM is debinding, where binders used in the metal powder injection process are thoroughly removed.

The choice of a debinding furnace is pivotal. The right furnace ensures complete binder removal while preventing issues like cracking or deformation, ultimately safeguarding the product’s final performance.

How do you select the perfect debinding furnace for MIM? This guide outlines key factors to consider, empowering you to achieve a seamless and efficient debinding process.

Debinding Process Types

MIM debinding processes include thermal, catalytic, and vacuum debinding, each suited to specific applications:

- Thermal Debinding: Heats parts at 200°C–550°C to decompose binders, ideal for medium- to low-precision parts. It’s cost-effective but time-intensive.

- Catalytic Debinding: Utilizes catalysts (e.g., nitric acid) at 150°C–250°C for rapid processing with minimal residue, making it ideal for high-precision MIM components.

- Vacuum Debinding: Heats in a vacuum environment (200°C–600°C), achieving ultra-low residual carbon (<0.1%), making it ideal for high-end applications such as medical or aerospace.

- CVSIC Recommendation: For high-precision parts, use catalytic or vacuum debinding furnaces; thermal debinding is suitable for standard components. Our multifunctional furnaces enable easy process switching for flexibility.

Temperature Control and Uniformity

- Requirement: MIM parts often have complex geometries, necessitating precise temperature control (±1°C) and uniform heating to prevent thermal stress-induced cracking.

- Key Considerations: Opt for a furnace equipped with multiple thermocouples and intelligent temperature control. CVSIC furnaces use advanced PID control, ensuring stable temperatures (as low as ±0.5°C deviations), which reduces scrap rates and improves yield for complex parts.

Atmosphere or Vacuum Control

Requirement: MIM materials, such as stainless steel or titanium alloys, are prone to oxidation and require protective inert gases (e.g., nitrogen, argon) or a vacuum environment.

Key Considerations:

- Atmosphere Debinding Furnaces: Require automated flow control and exhaust treatment systems to maintain gas purity.

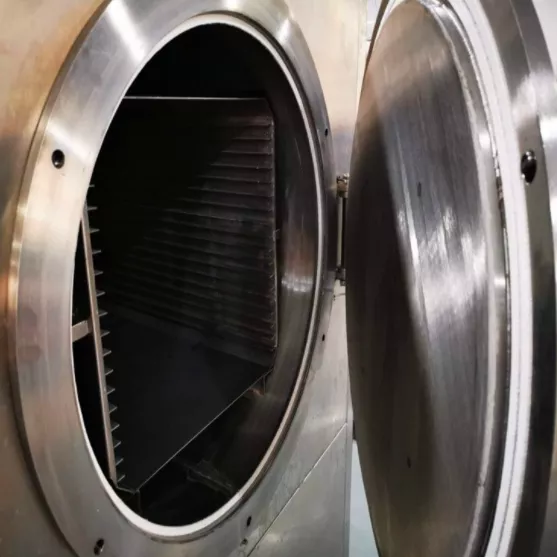

- Vacuum Debinding Furnaces: Must achieve vacuum levels below 10⁻² Pa to prevent leaks.

CVSIC Advantage: Our atmosphere furnaces feature precise flow meters that reduce gas usage by 15%, resulting in lower operating costs. Our vacuum furnaces feature helium mass spectrometry leak detection, simplifying maintenance and ensuring long-term reliability, thereby minimizing downtime and maintenance expenses.

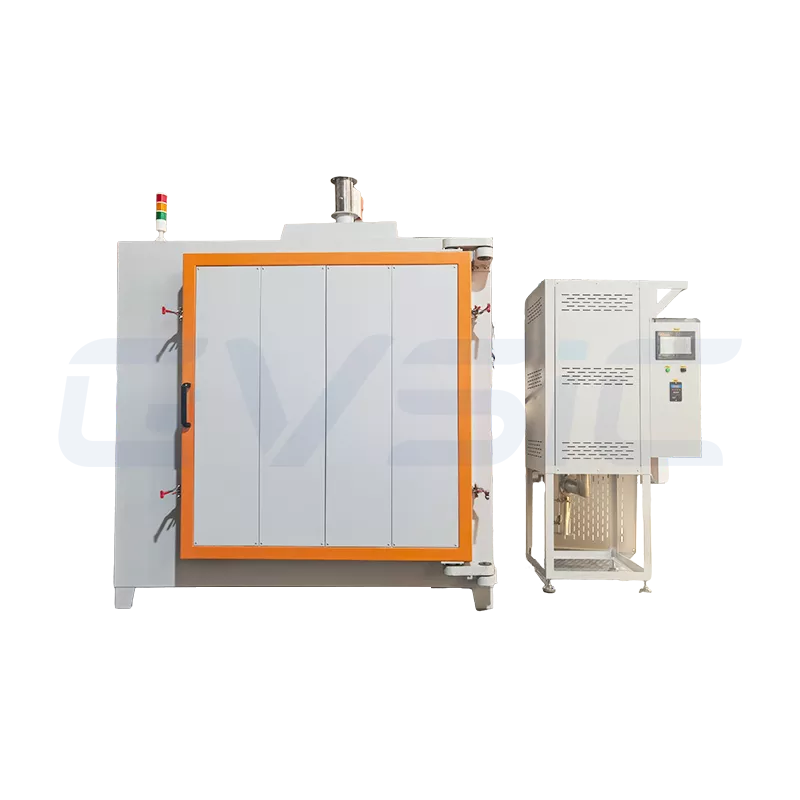

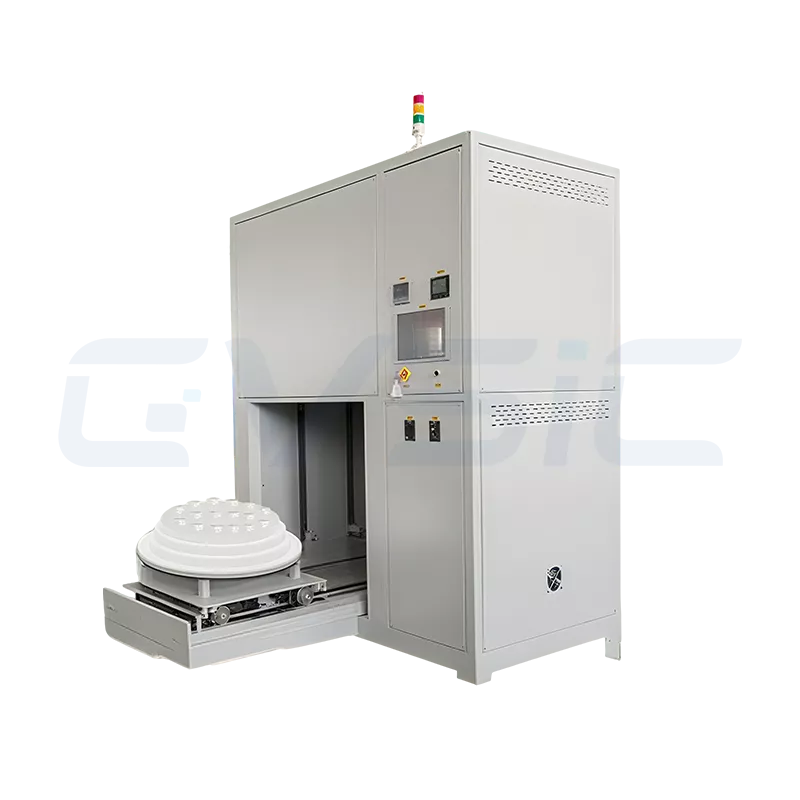

Obtain custom degreasing furnaces from CVSIC

Production Capacity and Furnace Chamber Size

- Requirement: The furnace size should align with the production volume. Small batches (<10 kg/batch) are suitable for laboratory furnaces (1–50L), while large batches require industrial furnaces (100L+).

- Key Considerations: Continuous furnaces are ideal for high output, while box-type furnaces are suited for small batches or R&D applications. Choose a furnace with a chamber space that is appropriately sized to avoid energy waste.

Additional Factors to Consider

Safety

- Requirement: Prevent risks such as explosions, leaks, or hazardous gas emissions.

- Recommendation: Select furnaces equipped with intelligent alarms and exhaust treatment systems. CVSIC furnaces feature multiple safety measures, including overtemperature cutoffs and gas leak alerts.

Energy Consumption and Cost

- Requirement: Cost and energy use are equally important when planning MIM production.

- Recommendation: Opt for energy-efficient furnaces. CVSIC’s insulation reduces energy use by up to 20%. For budget-minded users, start with a small furnace and upgrade when needed.

After-Sales Support

- Requirement: The complexity of MIM processes demands robust technical support.

- CVSIC Advantage: We provide free process testing, on-site installation guidance, and remote diagnostics. Customers consistently report that our support feels like having a dedicated engineer on call, expediting troubleshooting and maximizing equipment uptime.

Three Simple Steps to Choose Your Furnace

- Define Your Needs: Specify your materials (e.g., stainless steel, titanium alloys), production volume (daily output in kg), and precision requirements.

- Match Process to Furnace Type: Select catalytic or vacuum debinding furnaces for high-precision needs, or continuous atmosphere furnaces for high-volume production.

- Consult Our Experts: Contact CVSIC with your process parameters, and we’ll provide a customized selection plan at no cost.

Conclusion: Selecting the Right Debinding Furnace for MIM

Selecting a debinding furnace for MIM involves evaluating the process, atmosphere, vacuum control, efficiency, and safety. Every decision impacts product quality and operations, so tailor your choice to your requirements.

CVSIC offers specialized debinding furnace solutions for both small-batch R&D and large-scale production. Our expert team delivers optimized equipment configurations and ongoing technical support, ensuring you achieve consistent product quality and operational efficiency. Contact us today to receive personalized advice or discuss your specific requirements.