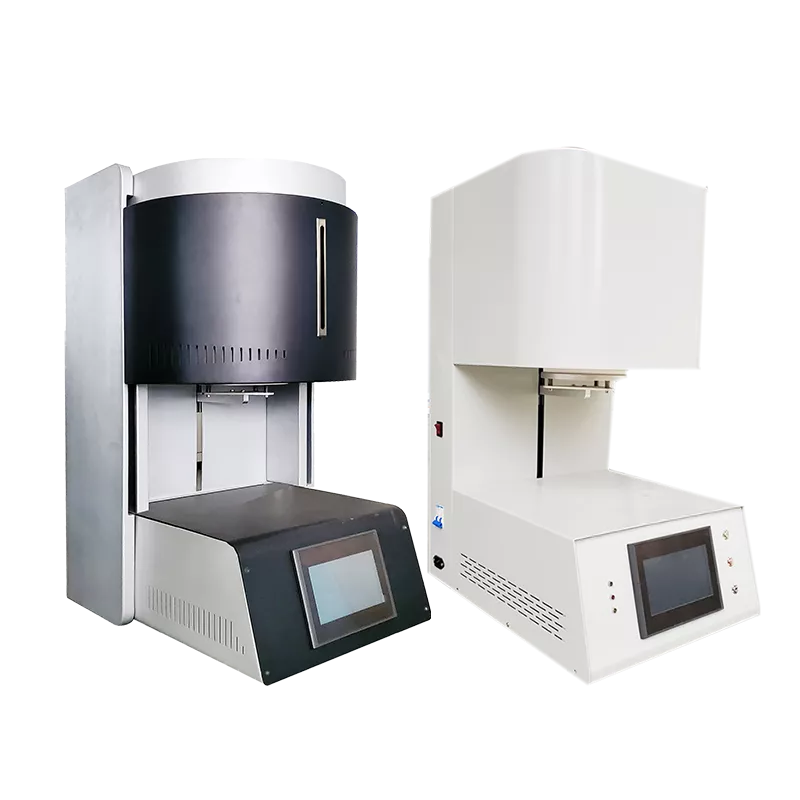

Introduction: Choosing the Ideal Sintering Furnace for Your Dental Laboratory

As an engineer, I recognize how the appropriate dental sintering furnace can significantly enhance your dental practice or lab. Whether you’re producing durable zirconia crowns or ensuring that restorations achieve optimal translucency, the sintering furnace serves as the core of any dental laboratory. However, with numerous models available in the market, how can you select one that is both effective and customized to your requirements? No need to worry — CVSIC offers a straightforward buying guide to assist you in easily locating the ideal equipment!

What is a Dental Sintering Furnace?

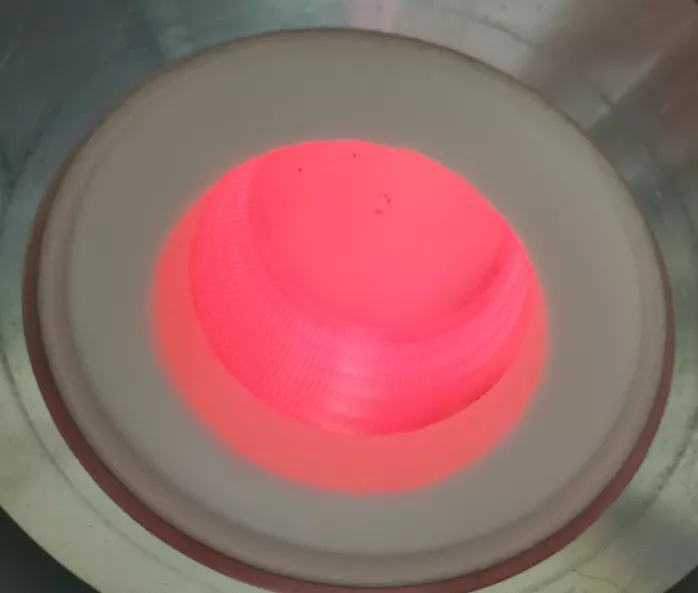

The dental sintering furnace is a specialized high-temperature device designed for sintering robust dental materials, such as zirconia. By utilizing accurate high-temperature heating (usually between 1400°C and 1600°C), it attains the optimal crystalline structure in zirconia, which leads to restorations that exhibit outstanding strength and translucency. The furnace plays a crucial role in the manufacturing of all-ceramic crowns, bridges, or implant abutments, ensuring a high standard of quality. Interested in how sintering furnaces are distinct from other types of dental furnaces? Please take a look at our Dental Sintering Furnaces vs. Porcelain Furnaces.

5 Key Factors for Selecting a Dental Sintering Furnace

When selecting a sintering furnace for your dental clinic or laboratory, these five key factors will help you make an informed decision:

1. Material Compatibility and Processing Requirements

Core Question: What types of materials does your lab mainly work with?

Dental Sintering furnaces are chiefly designed for processing zirconia, but they can also accommodate various high-melting-point materials, such as certain metal alloys. If your primary focus is on producing all-ceramic crowns or bridges, having a sintering furnace is crucial.

CVSIC Recommendation: Determine your material needs and choose a furnace model that supports those specific materials. Our zirconia sintering furnace is specifically optimized for zirconia, achieves yield rates as high as 99%.

2. Production Volume and Chamber Capacity

Key Consideration: What is your lab’s daily restoration output?

- Small Clinics: A capacity of 5-10 restorations per day is ideal for compact sintering furnaces with smaller chamber sizes (approximately 1-2 sintering trays).

- Large Labs: For processing 50 or more restorations each day, you’ll need high-throughput sintering furnaces equipped with multi-layer sintering trays for enhanced efficiency.

CVSIC Highlight: Our range of sintering furnaces includes everything from compact desktop models to larger high-throughput solutions, suitable for laboratories of varying sizes.

3. Temperature Control and Uniformity

Key Consideration: How accurate is the temperature control in the furnace?

- Zirconia sintering requires precise temperature management and consistent chamber heating. Significant temperature variations can result in material cracking or uneven performance. A high-end sintering furnace should offer: an intelligent temperature control system with support for multi-stage heating and cooling profiles.

- Superior heating elements (e.g., MoSi2 Heating Elements) to guarantee even temperature distribution throughout the chamber.

CVSIC Advantage: Our sintering furnaces utilize advanced PID temperature control technology, ensuring temperature fluctuations are kept within ±1°C—perfect for zirconia sintering.

4. Operational Ease and Intelligence

Core concern: Is the equipment easy to use?

Contemporary sintering furnaces should come with user-friendly interfaces such as touchscreens and pre-set programs, allowing technicians to set up sintering curves quickly. For smaller clinics in particular, straightforward operation greatly enhances efficiency.

CVSIC Recommendation: Our furnaces support up to 100 custom programs and feature an intuitive touchscreen interface, making them easy to operate, even for beginners.

5. After-Sales Service and Maintenance Support

Key Question: What should you do if the equipment experiences issues?

- Given their value, sintering furnaces require dependable after-sales service and maintenance support. When choosing a brand, confirm the availability of scheduled maintenance and calibration services.

- Ensure there is access to a fast-response technical support team.

CVSIC Commitment: We offer 24/7 global technical support and OTA firmware updates, ensuring your equipment stays in top condition.

Want additional purchasing advice? Visit our Dental Furnaces Guide

Other Considerations

1. Equipment Size and Space

Compact sintering furnaces are perfect for small clinics that have limited space.

For larger laboratories, multi-functional or high-capacity models are preferred for enhanced efficiency and versatility.

CVSIC Recommendation: Our desktop sintering furnaces are tailored for small clinics, designed to take up minimal space while maintaining excellent performance.

2. Energy Consumption and Environmental Impact

Since sintering furnaces run for long durations, their energy consumption is an essential consideration. Opting for energy-efficient models can lead to lower operational costs over time.

CVSIC sintering furnaces incorporate high-efficiency heating elements and improved insulation design, resulting in energy savings of up to 20%.

3. Budget and Cost-Effectiveness

The cost of sintering furnaces can vary widely depending on their features and brand, with prices ranging from several thousand to tens of thousands of dollars.

CVSIC Recommendation: Choose a model that fits your budget, focusing on durability and after-sales support to prevent frequent repairs related to lower-cost equipment.

Tips for Using and Maintaining Sintering Furnaces

Picking the right sintering furnace is only the beginning. Proper operation and routine maintenance will enhance the equipment’s lifespan. Here are some valuable suggestions:

Usage Tips

- Clean the furnace chamber before each sintering cycle to avoid contamination of zirconia by impurities.

- Utilize the recommended sintering discs and support materials to achieve even heating of restorations.

- Choose suitable sintering curves according to the type of material to prevent cracking from rapid heating rates.

Maintenance Recommendations

- Regularly check heating elements (like silicon molybdenum rods) for signs of wear and replace as necessary.

- Remove zirconia residue from the furnace chamber to maintain the quality of subsequent sintering.

- Periodically calibrate temperature sensors to guarantee accurate temperature regulation.

Want more maintenance details? Check out our dental furnace maintenance !

Why Select CVSIC Sintering Furnaces?

At CVSIC, we recognize the ongoing commitment of dental laboratories to efficiency and excellence. Our furnaces provide outstanding performance, specifically designed for the dental field:

- Superior Temperature Control: Guarantees zirconia restorations attain optimal strength and visual appeal.

- Variety of Choices: Ranging from compact to high-capacity models, suited for different practice sizes.

- Extensive Support: International after-sales service, round-the-clock technical support, and OTA firmware updates.

- Ongoing Innovation: New furnace models are introduced each year to stay in line with industry developments.

Explore CVSIC’s dental furnace today and discover the ideal sintering furnace for your laboratory!

FAQ

Which sintering furnace is suitable for small dental clinics?

Small clinics should select compact, easy-to-operate furnaces with a chamber capacity that supports 1-2 sintering trays.

How critical is temperature control precision in sintering furnaces?

Extremely important! Significant temperature deviations can cause zirconia fractures or inconsistent performance. CVSIC furnaces achieve a temperature control precision of ±1 °C, ensuring high-quality results.

How long does the sintering process take?

Zirconia sintering typically requires 6-8 hours, including heating, holding, and cooling. CVSIC models support rapid sintering modes, reducing time to 4 hours in specific scenarios.

How do I determine if a sintering furnace’s chamber capacity is sufficient?

Select based on daily restoration output. Small clinics should choose chambers that support 10-20 restorations, while large laboratories may opt for high-throughput models that accommodate over 50 units.

Does CVSIC offer customized sintering furnace solutions?

Yes! We provide bespoke furnace designs tailored to specific material and production requirements. Contact us for more information!

Conclusion

Choosing the appropriate dental sintering furnace enhances your lab’s productivity and ensures superior restorations that meet patient expectations. CVSIC is dedicated to offering high-quality, dependable sintering furnace options to support your success in the dental sector. Interested in finding out more? Check out our Dental Furnace Products or reach out to our technical team today!