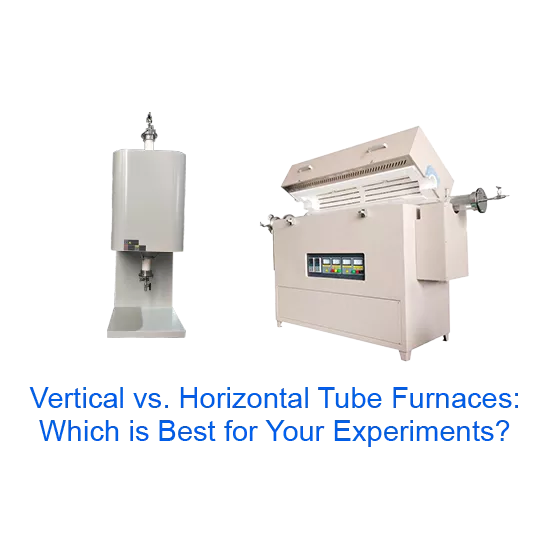

Tube furnaces are essential for high-temperature lab and industrial work. If your samples are burnt on one side and underprocessed on the other, uneven heating could be affecting your results.

“Why does my tube furnace display a steady temperature, yet samples heat inconsistently?” This is a common issue in research and material sintering. Uneven heating can lead to failed experiments, defective products, or increased costs. Drawing on years of expertise, CVSIC explains the primary causes of uneven heating in tube furnaces and provides practical solutions for achieving consistent results.

Common Causes of Uneven Heating in Tube Furnaces

Uneven heating results from equipment or operational issues. Common causes include:

- Temperature gradients can form inside the furnace tube. Heating elements are outside the tube, so samples near them heat faster. Tube ends stay cooler, especially in long tubes or single-zone furnaces.

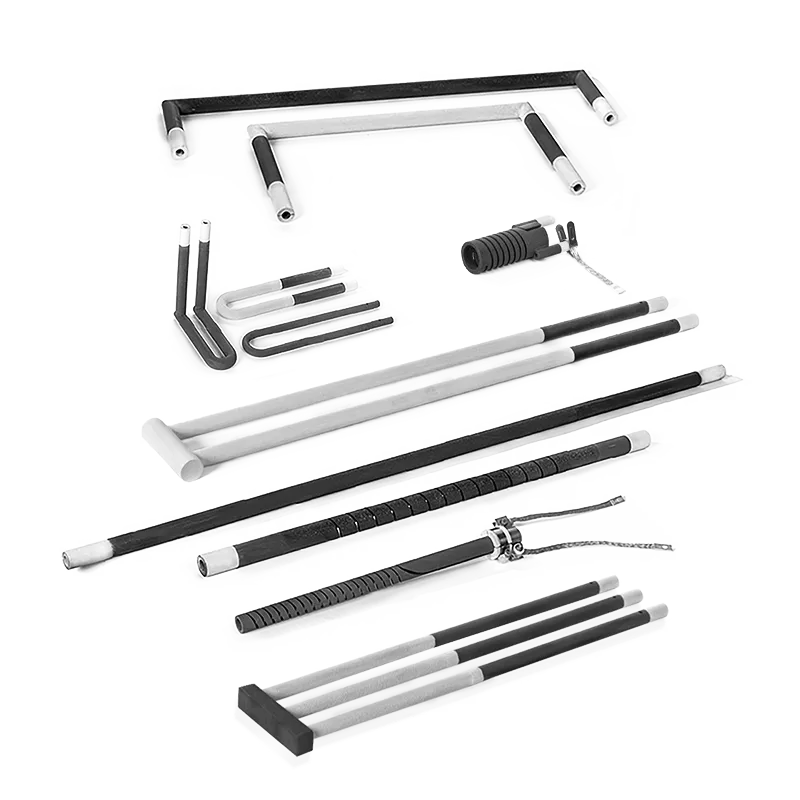

- Aging heating elements: Over time, silicon carbide or molybdenum disilicide heating elements degrade, leading to uneven heat distribution.

- Improper sample loading: Overstacked samples or placement away from the heating center can result in inconsistent heating. For instance, powder samples piled on one side may clump or overheat locally.

- Temperature control issues: Incorrect PID controller (a device that regulates temperature) settings or a misaligned thermocouple (the temperature sensor) can cause temperature fluctuations or deviations.

- Atmosphere or vacuum inconsistencies: Uneven gas flow or insufficient vacuum levels can disrupt heat conduction, creating localized temperature differences.

- Limited temperature monitoring: Relying on a single thermocouple (temperature sensor) fails to capture the full temperature profile across the furnace tube.

Having explored the main causes of uneven heating, let’s move on to practical solutions. CVSIC’s straightforward and effective strategies serve both novice and experienced users alike.

Five Effective Solutions for Uniform Heating

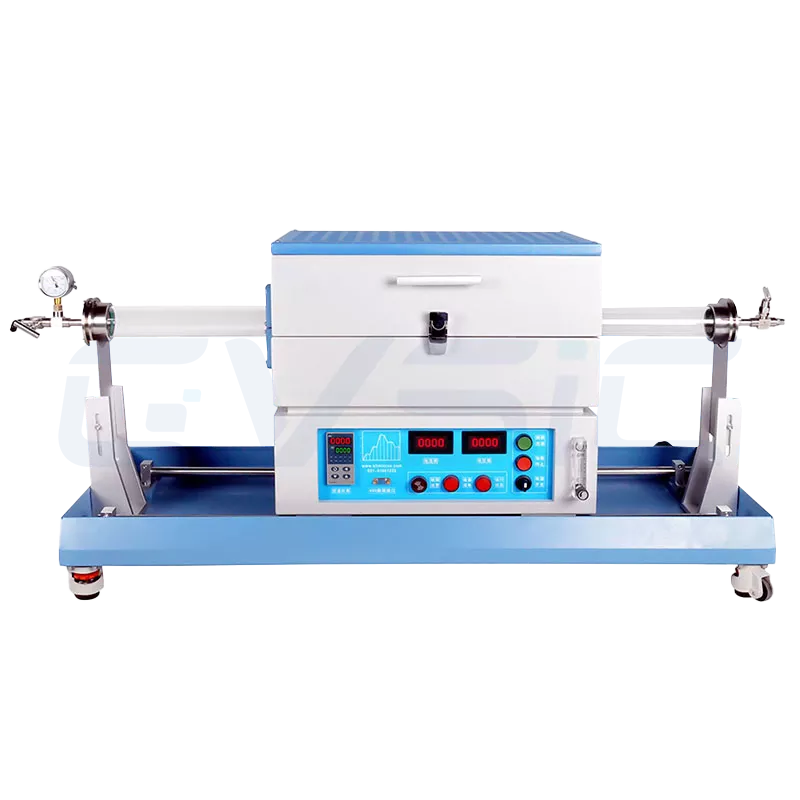

Select the Right Furnace: Multi-Zone Tube Furnaces

- For experiments requiring high temperature uniformity, consider a dual-zone or three-zone tube furnace.

- These allow independent temperature control by zone, offsetting thermal gradients with programmable settings.

Optimize Sample Loading

Sample placement and distribution have a significant impact on heating consistency. Implement these techniques:

- Central placement: Position samples in the furnace tube’s central heating zone (typically the middle section) to avoid cooler areas near the tube ends. CVSIC furnaces include marked reference lines to simplify positioning.

- Prevent overstacking: Spread the powder samples evenly, maintaining a thickness of 1–2 cm for optimal heat transfer. Secure larger samples in special crucibles.

- Dynamic movement: For powder-based experiments, CVSIC’s rotary tube furnaces promote uniform heating through dynamic tumbling. For static furnaces, periodically flip samples manually to enhance consistency.

Maintain and Replace Heating Elements

Heating elements are crucial to a tube furnace’s performance, and their degradation can lead to localized temperature variations. Here’s how to address this:

- Routine inspections: Check the resistance and wear of heating elements (the furnace’s parts that generate heat) every 6–12 months.

- Group replacement: Replace elements as a complete set to avoid inconsistencies from mixing new and old components.

- Temperature recalibration: After you replace heating elements, use a thermocouple. This helps you adjust the system for even heating.

- CVSIC’s heating elements deliver long-lasting, uniform heating.

- Tip: Track use and replace every 2,000–3,000 hours to avoid failures.

Fine-Tune Temperature Control Settings

The PID controller (a device that automatically keeps the temperature steady) serves as the furnace’s control center, and suboptimal settings can lead to temperature instability. Try these adjustments:

- Verify thermocouple placement: Ensure the thermocouple (temperature sensor) is positioned at the heating center and in contact with the tube’s inner wall to avoid misalignment.

- Optimize PID parameters: Adjust PID values (P, I, D) to fix fluctuations. CVSIC features default settings, as well as advanced tuning support.

- Use multi-zone furnaces: Single-zone models often have temperature differences at the ends. Upgrading to CVSIC’s multi-zone furnaces gives each zone independent control. This can improve uniformity by up to 30%.

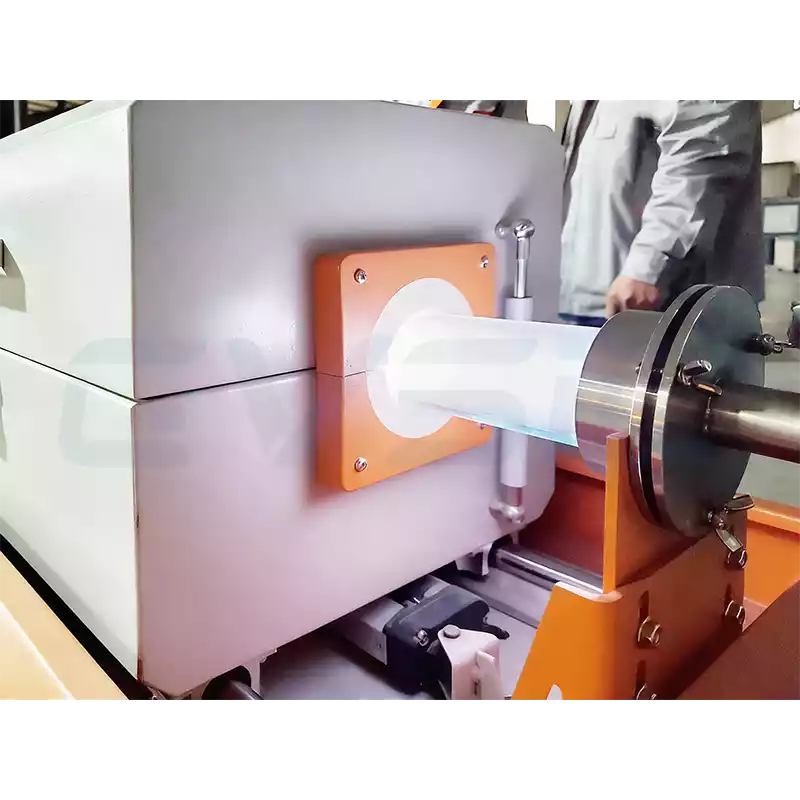

Enhance Atmosphere or Vacuum Conditions

Inconsistent gas flow or inadequate vacuum levels can impair heat conduction, leading to uneven temperatures. Solutions include:

- Ensure proper sealing: Verify that flanges and seals are leak-free. CVSIC’s atmosphere furnaces feature durable, easy-to-replace sealing components.

- Streamline gas flow: In atmosphere furnaces, ensure even gas distribution to prevent turbulence. CVSIC’s furnaces incorporate gas guide channels to minimize dead zones.

- Maintain high vacuum levels: For vacuum furnaces, service pumps and change pump oil regularly. Aim for a vacuum degree of 10^-3 Pa or better.

- Tip: Using high-purity gases, such as 99.999% argon, can also help temperature uniformity. CVSIC gives guidance on gas selection.

Upgrade Furnace Tubes or Select Optimal Materials

The material and condition of the furnace tube directly influence heat conduction. Address these common issues:

- Choose high-conductivity materials: Quartz tubes are ideal for low-temperature applications (operating below 1200°C), while corundum or zirconia tubes excel at high temperatures (above 1500°C). CVSIC’s corundum tubes ensure uniform heat transfer and exceptional durability.

- Inspect for damage: Cracks or contaminants can disrupt the flow of heat. Clean or swap tubes often; CVSIC’s quick replacements cut downtime.

- Select appropriate tube dimensions: Tubes that are too long or short can create temperature disparities. CVSIC offers customized tube lengths tailored to your experimental needs.

Purchase high-performance tube furnaces from Chinese tube furnace manufacturer

Preventing Uneven Heating: Proactive Maintenance Tips

Prevention is key to maintaining consistent performance. CVSIC recommends the following practices:

- Regular cleaning: Clean tubes regularly to reduce thermal resistance. CVSIC cleaning kits simplify this.

- Document experiment details: Record where you place samples, the temperature profile, and gas flow for each test. This helps you find and fix issues quickly.

- Invest in reliable equipment: CVSIC’s tube furnaces offer optimized heating and advanced temperature control, minimizing the risk of uneven heating.

Case Study

A client’s sintering of lithium battery cathode materials frequently encounters uneven powder processing. Investigation revealed:

- Use of a single-zone tube furnace.

- Samples loaded across half the tube length.

- Temperature monitoring was limited to one central thermocouple. After upgrading to a three-zone rotary tube furnace and improving the atmosphere flow, we achieved a 30% improvement in material uniformity. Product quality and yield have increased significantly.

FAQ

Why is my tube furnace, which has been in use for several years, showing increasingly uneven heating?

This is likely due to aging heating elements or variations in resistance. Inspect and replace the elements as needed.

What issues arise from uneven heating in a tube furnace?

Uneven heating can cause localized overheating or underprocessing, compromising experiment reproducibility or product quality, and in severe cases, leading to sample loss.

How can I tell if heating elements need replacement?

Replace elements if temperature deviations exceed ±5°C or if they show visible oxidation or cracking.

Is a multi-zone tube furnace the only solution for uneven heating?

Not necessarily. Proper sample placement and atmosphere optimization can improve uniformity in single-zone furnaces. However, for stringent requirements, multi-zone furnaces are highly recommended.

How can I address uneven heating in an atmosphere furnace?

Ensure consistent gas flow and robust sealing. CVSIC’s atmosphere furnaces incorporate flow-guiding designs to minimize temperature variations.