Selecting a muffle furnace primarily depends on the heating element, which influences maximum temperature, longevity, efficiency, and outcomes.

Common heating materials in muffle furnaces include:

- Resistance wire (FeCrAl or NiCr alloys)

- Silicon carbide (SiC) elements

- Molybdenum disilicide (MoSi₂) elements

These materials determine operating limits, ramp rates, durability, and maintenance. CVSIC provides the optimal operating temperature range for different heating elements while considering their service life, maximizing your efficiency.

While each heating element can withstand higher temperatures, doing so accelerates damage and is not the optimal solution. For example, CVSIC’s SiC Heating Elements can reach up to 1620°C, but we recommend operating them only between 1400–1550°C. For higher temperature requirements, Mosi2 heating elements offer better cost-effectiveness.

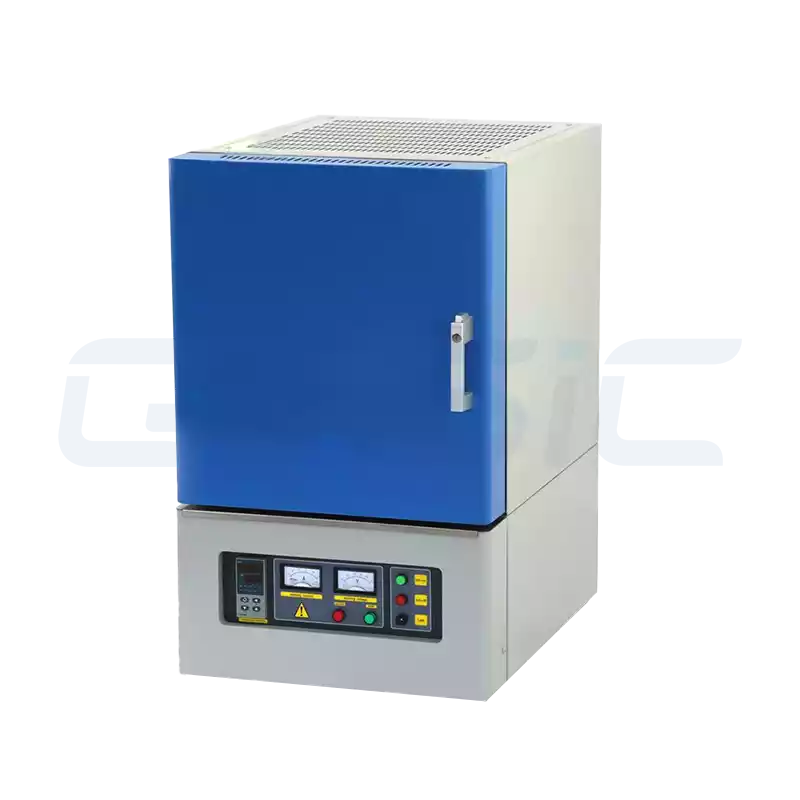

Resistance Wire: The Reliable Choice for Up to 1100°C

Key Features:

- Material: Fe-Cr-Al or Ni-Cr alloys

- Max Temperature: 1100°C

- Cost: Low

- Control: Excellent stability for extended runs

Ideal Applications:

Lab ash analysis, powder drying, low-temp annealing, and glass degassing.

Pros and Cons:

- Affordable and easy to maintain

- Uniform heating distribution

- Susceptible to oxidation at elevated temperatures, shortening service life

- Ill-suited for rapid cycling or high-heat demands

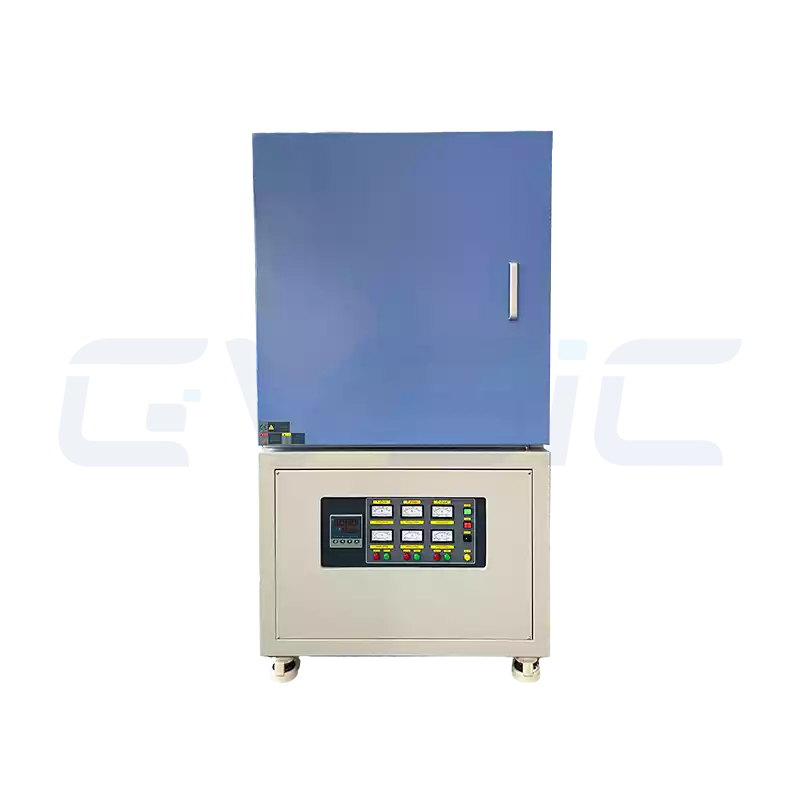

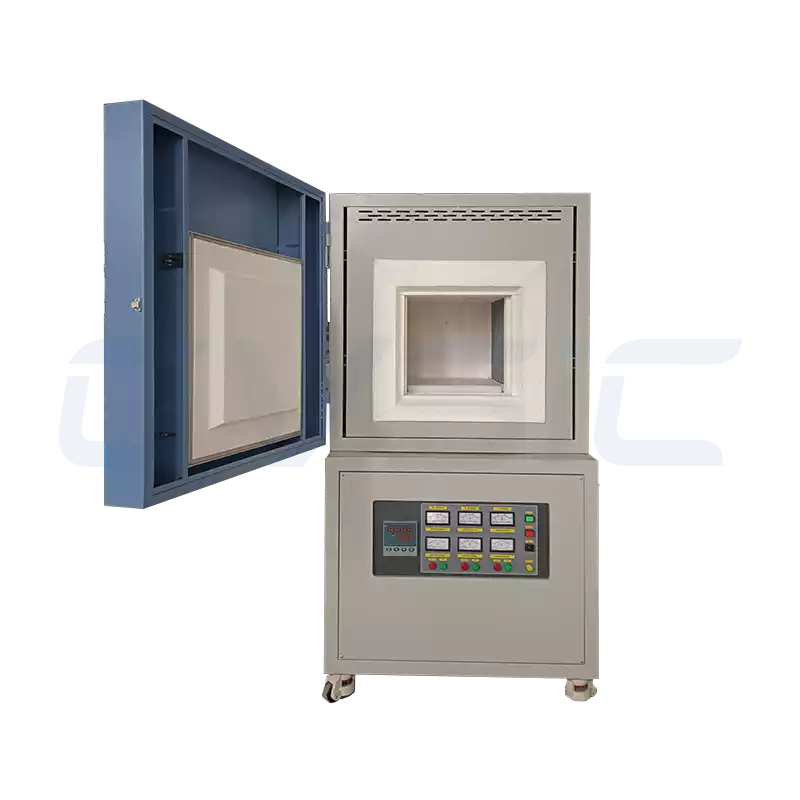

SiC Elements: Versatile Powerhouse for 1400–1550°C

Key Features:

- Material: Silicon carbide (SiC)

- Max Temperature: 1625°C

- Resistance Profile: Gradually increases over time

CVSIC SiC Heating Elements for Sale

Ideal Applications:

Ceramic sintering, metal heat treatment, glass sealing, and material annealing.

Pros and Cons:

- Rapid ramp-up with strong resistance to oxidation and thermal shock

- Balanced cost with extended service intervals

- Requires periodic electrical recalibration due to resistance drift

- Avoids frequent power cycling

Featured Models:

CVSIC 1400°C series Muffle Furnace.

MoSi2 Elements: Elite Option for 1700–1800°C Extremes

Key Features:

- Material: Molybdenum disilicide (MoSi₂)

- Max Temperature: 1850°C

- Self-Protection: Develops a dense SiO₂ passivation layer

CVSIC Mosi2 Heating Elements for Sale

Ideal Applications:

Alumina and zirconia ceramic sintering, electronic ceramics, functional materials R&D, metal powder debinding, high-temp tempering.

Pros and Cons:

- Sustained stability beyond 1700°C

- Superior oxidation and shock resistance with quick response times

- Premium pricing, plus stringent needs for chamber sealing and power compatibility

To highlight the distinctions, the comparison chart shows that MoSi₂ excels in peak temperature and durability, SiC leads in ramp speed, and resistance wire offers unbeatable economy.

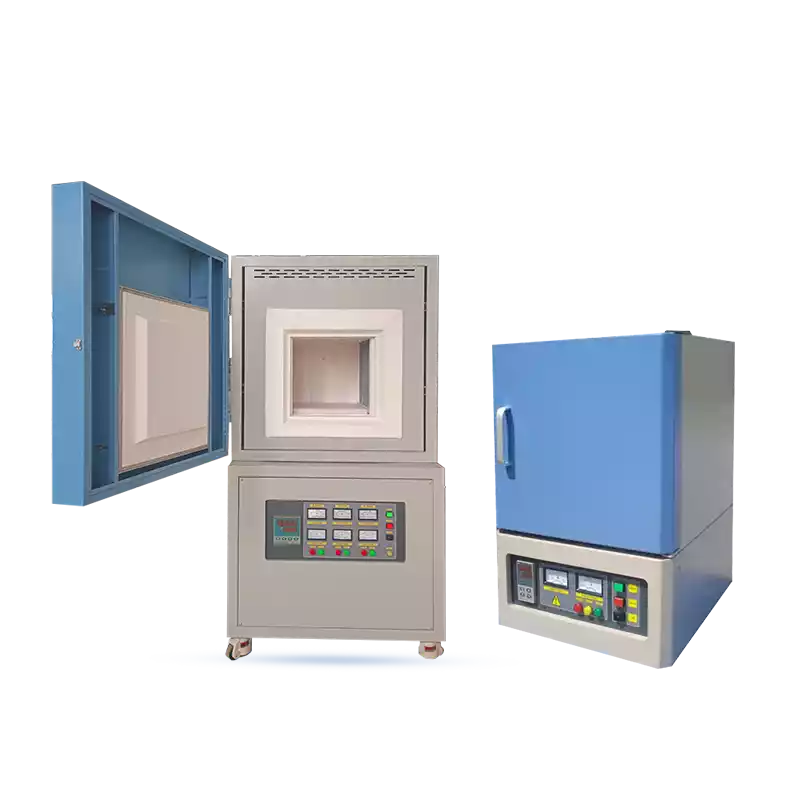

High Temperature Muffle Furnaces

Muffle Furnace Heating Elements: At-a-Glance Comparison

| Heating Element Type | Max Temperature (°C) | Cost | Service Life | Ramp Speed | Key Advantages | Key Drawbacks | Typical Uses |

| Resistance Wire | ≤1100 | Low | Medium | Medium | Low cost, simple maintenance | Short life, poor high-heat tolerance | Lab analysis, drying, annealing |

| SiC | ≤1550 | Medium | Medium-High | Fast | Quick heating, high efficiency | Limited oxidation resistance | Ceramics, metals, glass sintering |

| MoSi₂ | ≤1850 | High | High | Very Fast | Oxidation-proof, long-lasting, stable at extremes | High cost, brittle nature | High-temp ceramics, powder metallurgy, functional materials |

Guidance for Selecting the Right Heating Element

Tailor your choice to these critical factors:

Temperature Requirements:

- ≤1200°C: Go with resistance wire for cost-effective reliability.

- 1200–1550°C: SiC delivers optimal value.

- 1600–1850°C: MoSi₂ is essential—CVSIC’s 1800°C muffle furnaces shine here.

Materials and Processes:

- Ashing or annealing: Resistance wire handles it effortlessly.

- Ceramic sintering or metal treatment: SiC provides the edge.

- For high-temperature ceramics or glass melting, MoSi₂ is the go-to.

Budget and Maintenance:

- Tight budgets: Resistance wire models.

- Balanced investment: SiC-equipped furnaces.

- Premium performance: MoSi₂ with CVSIC customization.

In Summary: Match the Element to Maximize Results

Each type excels in its niche—resistance wire for economy, SiC for balanced power, and MoSi₂ for high-heat challenges.

CVSIC muffle furnaces provide reliable, efficient heating at any temperature.

FAQ

Can resistance wire, SiC, and MoSi₂ elements be combined?

Not advised—mismatched thermal profiles and responses can lead to uneven heating or premature failure.

Which is more energy-efficient, SiC or MoSi2?

MoSi2 edges out with superior efficiency and quicker response at equivalent temps, though upfront costs are higher.

Can MoSi2 substitute for SiC?

Yes, but it’s overkill (and pricier) for 1200–1400°C tasks where SiC suffices.

Can SiC handle 1700°C experiments?

No—prolonged exposure triggers rapid oxidation and breakdown.

Tips for extending heating element life?

Operate below rated limits, minimize thermal shocks from rapid heating/cooling, and inspect chamber insulation routinely.