PID stands for Proportional-Integral-Derivative control—a proven, precise thermal management algorithm.

In muffle furnaces, PID controllers continuously adjust heating power to minimize the gap between setpoint and real-time temperature, keeping performance steady with minimal overshoot.

Think of it as a seasoned overseer: It ramps up, eases off, and fine-tunes for smooth, accurate heating.

Understanding PID Control

PID is a feedback loop that keeps furnace temperatures within tight tolerances, using three key components:

- Proportional (P): Scales output based on current error (setpoint minus actual temp), providing immediate correction to close the gap swiftly.

- Integral (I): Accumulates past errors over time, wiping out lingering offsets for spot-on steady-state accuracy.

- Derivative (D): Anticipates shifts by tracking the rate of change, acting as a buffer against spikes or dips for smoother transitions. For precision-driven applications, this trio ensures reliable heating, unwavering stability, and adaptive responses—vital for reproducible results.

PID’s Impact on Muffle Furnace Performance

At the heart of effective temperature management, PID transforms basic heating into intelligent control. Key benefits include:

Precision Temperature Profiling

- On/off controls cycle fully on or off, causing erratic swings.

- PID’s modulated approach yields gradual ramps and reduced overshoot, resulting in cleaner profiles. Case in Point: In a 1200°C muffle furnace, PID slashed fluctuations from ±15°C to under ±2°C, boosting consistency in ash assays and powder sintering.

Sustained Thermal Stability

- It scales power efficiently, preventing wasteful oscillations.

- PID adapts to ambient shifts and stays steady for hours or days. Great for uniform-critical processes like ceramic sintering or alloy annealing. CVSIC’s PID systems can maintain <±1°C variance.

Lab-Tested Data (CVSIC Benchmarks):

| Control Method | Energy Use (kWh) | Fluctuation | Ramp Time to 1000°C |

| ON/OFF | 9.8 | ±14°C | 68 min |

| PID | 8.3 | ±2°C | 54 min |

Results: 15% energy savings, plus less wear on elements from thermal cycling.

Element Protection and Extended Longevity

- Wild swings stress SiC or MoSi₂ components, leading to expansion/contraction fatigue and risking cracks or degraded coatings.

- PID’s gentle temperature ramps minimize thermal shocks, preserving element integrity. Real-World Gains: CVSIC’s 1700°C PID-equipped models extend Mosi2 heating element service life by 25–35% on average.

Versatile Multi-Stage Programming

Tailored profiles are essential for materials such as ceramics, powders, and glass that require phased heating. PID enables customizable segments:

- Stage 1: Gentle warmup to vent moisture.

- Stage 2: Accelerated climb to peak.

- Stage 3: Prolonged hold for processing.

- Stage 4: Controlled cooldown to avert cracks. Elevating your furnace from a simple heater to a full process orchestrator.

Visual: Precision Comparison Chart (This chart will illustrate temperature stability and overshoot comparison between PID and traditional ON/OFF control curves. Data source: CVSIC internal benchmarking.)

Real-World PID Applications

| Sector | Tolerance Needs | Typical Temps (°C) | PID Edge |

| Lab Analysis | ±1–2°C | ≤1100 | Enhanced repeatability |

| Ceramic Sintering | ±3°C | 1400–1600 | Consistent densification curves |

| Metal Annealing | ±2°C | 800–1300 | Prevents grain overgrowth |

| Glass Softening | ±5°C | 1200–1700 | Mitigates stress fractures |

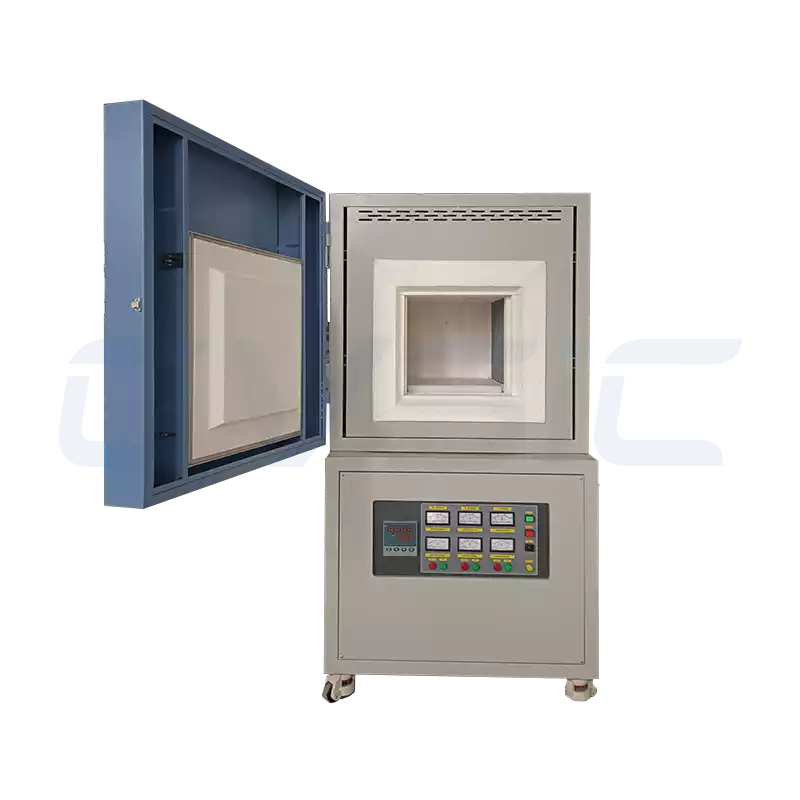

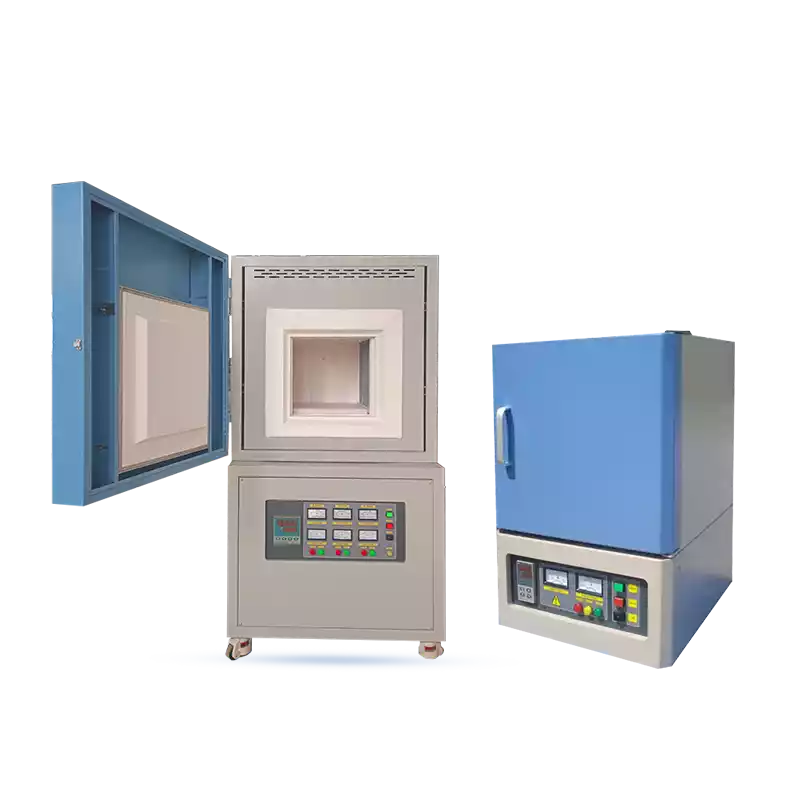

CVSIC’s Advanced PID Systems

Every CVSIC muffle furnace uses a robust PID module offering:Up to 50 programmable ramp/hold segments.

- ±1°C precision across the board.

- Auto-tuning for effortless optimization.

- SSR outputs for silent, rapid switching without contacts.

- Optional RS485 for remote oversight. We offer OEM/ODM options, including multi-zone independence and energy analytics.

Pro Tips to Leverage PID Fully

- Calibrate Routinely: Recheck parameters every 6 months to account for aging.

- Program Smartly: Use stepped ramps for delicate materials.

- Log and Analyze: Pull temperature histories for proactive tweaks.

- Seek Guidance: Our team provides custom tuning—reach out anytime.

In Summary

PID isn’t just control—it’s the intelligent core driving furnace reliability, efficiency, and durability.

As CVSIC engineers often say: “Pair a top-tier element with sharp PID, and you’ve got a powerhouse; without it, even the best setup lacks control—like a sports car sans brakes.”

When spec’ing your next furnace, insist on PID integration—it’s the linchpin for safe, stable operations.

FAQ

Does PID require manual tweaks?

A: CVSIC units auto-tune by default. Recalibrate after element changes.

Multi-zone support?

A: Yes, dual- and tri-zone PID allows precise gradients.

Does PID slow ramps?

A: No, PID delivers faster, stable heating with less energy waste.