With over 20 years of experience in high-temperature industrial applications, I understand the crucial role protective gases play in atmosphere furnaces. Acting as “invisible guardians,” they determine workpiece quality and process effectiveness. Customers often ask: “Hydrogen, nitrogen, or argon—which should I choose?” While seemingly simple, this decision depends on specific process needs. CVSIC provides a concise analysis of these three shielding gases to help you find the best solution.

Why Use Protective Gases?

In high-temperature furnaces, protective gases prevent oxidation and unwanted reactions, thereby maintaining the quality of the workpiece. For example, metal powders oxidize easily in air, while ceramics need an inert environment for crystal formation. Protective gases act as a “protective suit,” allowing ideal conditions at high temperatures.

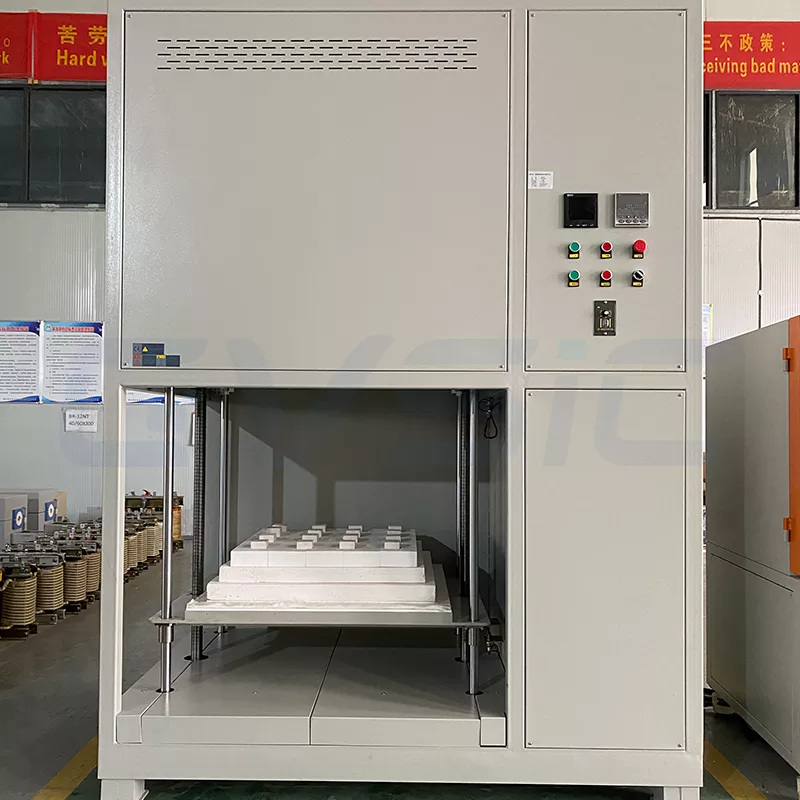

CVSIC’s atmosphere furnaces utilize advanced gas control systems that support multi-gas switching and precise ratio adjustments, enabling them to adapt to complex requirements. Next, we’ll analyze the characteristics of hydrogen, nitrogen, and argon to help you find the most suitable option.

Hydrogen (H₂): Highly Reducing, Requires Careful Handling

Characteristics:

Hydrogen is a highly effective reducing gas that removes surface oxides from workpieces, making it suitable for processes requiring strong reduction. Its high thermal conductivity enables uniform heat distribution. The primary limitation is its extreme flammability, requiring rigorous safety controls.

Advantages

- Strong reducing power: Fundamentally prevents metal oxidation, excelling in powder metallurgy (e.g., part sintering) and metal heat treatment (e.g., annealing processes) to shield workpieces from oxygen corrosion.

- Enhanced material properties: Improves surface finish and mechanical strength in certain alloy processing, delivering superior finished product quality.

- Relatively low cost: Compared to premium gases like argon, hydrogen offers lower procurement expenses.

Disadvantages

- Safety risks: Hydrogen’s flammability necessitates comprehensive safety systems, including leak detectors and automatic shut-off valves.

- Stringent equipment requirements: Furnace sealing and gas control systems must be stable and reliable. Leaks not only disrupt processes but may also trigger safety incidents.

Applications

- Powder metallurgy: High-temperature sintering of cemented carbides and stainless steel components, where hydrogen prevents oxidation to ensure part strength and precision.

- Metal heat treatment: Annealing processes for copper or titanium alloys, relying on hydrogen’s reducing environment to avoid surface oxide layer formation.

- Special materials: Preparation of magnetic materials requiring reducing atmospheres, where hydrogen provides an ideal synthesis environment to guarantee performance standards.

CVSIC Tip

With the handling needs of hydrogen in mind, our furnaces employ layered safety measures, including real-time monitoring and emergency relief systems. We also offer precise flow control for optimal reduction.

Nitrogen (N₂): The Cost-Effective “All-Purpose Solution”

Characteristics:

Nitrogen is the most economical inert gas, highly stable and rarely reactive, making it broadly useful across processes that do not require reducing atmospheres.

Advantages:

- Low cost: Nitrogen is extremely widely available and significantly cheaper than comparable inert gases like argon, making it ideal for cost control in large-scale, high-volume production.

- High safety: As a non-flammable gas, nitrogen poses no fire or explosion risks during storage, transportation, or use, greatly reducing operational safety hazards.

- Versatility: Processes not reliant on specific chemical reactions can generally utilize nitrogen, demonstrating stable adaptability from basic industrial processing to precision manufacturing.

Disadvantages:

- Limited inertness: In extremely high-temperature environments or when interacting with specific materials (e.g., titanium alloys), nitrogen may undergo trace reactions with workpieces, potentially affecting critical product properties like mechanical strength and purity.

- Purity Requirements: Low-purity nitrogen may contain trace oxygen that compromises protective efficacy.

Applications:

- Ceramic Sintering: Effectively prevents oxidation of ceramic blanks during sintering processes for materials like alumina and silicon nitride.

- Metal Heat Treatment: Suppresses surface oxidation and discoloration in critical processes such as annealing or tempering of stainless steel.

- Laboratory Research: Suitable for cost-sensitive small-scale experiments (e.g., material synthesis, sample preservation).

CVSIC Tip:

Our furnaces offer stable, high-purity nitrogen and gas purification to maintain environmental purity. We tailor nitrogen flow to your process for optimal cost and efficiency.

Argon (Ar): The Premium Choice for High-End Inert Gases

Characteristics:

Argon is the most stable inert gas, rarely reacting, and is suitable for processes requiring very pure atmospheres. Its cost limits it to premium uses.

Advantages:

- Ultra-high inertness: Ideal for materials sensitive to oxygen or nitrogen, such as titanium alloys and semiconductor materials.

- Exceptional stability: Maintains stability at ultra-high temperatures (>1600°C), meeting demanding process requirements in aerospace and high-end manufacturing.

- Superior cleanliness: Argon’s inherent high purity minimizes impurity contamination of workpieces.

Disadvantages:

- High cost: Procurement expenses and storage requirements significantly exceed those of nitrogen and hydrogen.

- Low thermal conductivity: Compared to hydrogen, argon’s heat transfer efficiency is lower, potentially affecting temperature uniformity within furnace chambers.

Applications:

- New material R&D: Preparation processes for graphene, nanomaterials, or high-temperature superconductors.

- Semiconductor industry: Core processes like silicon wafer annealing or crystal growth.

- High-end metal processing: Heat treatment of high-performance metals such as titanium alloys and nickel-based alloys.

CVSIC Tip:

We’ve optimized our furnace chambers for argon to maintain uniform temperature and atmosphere. Gas recovery systems help cut overall costs.

How to Select the Right Shielding Gas?

When choosing a shielding gas, follow these key steps for clarity and effectiveness:

- Define Material Sensitivity: Is your workpiece reactive to oxygen or nitrogen? For instance, titanium alloys demand argon, while stainless steel can often use nitrogen.

- Identify Process Goals: Choose hydrogen if a reducing atmosphere is required (such as for deoxidation). Use nitrogen or argon when an inert atmosphere is the primary objective.

- Assess Budget Constraints: Nitrogen is the most budget-friendly, argon is the premium option, and hydrogen sits between—factor in additional costs for hydrogen safety equipment.

- Evaluate Safety Requirements: Hydrogen necessitates the strictest safety standards, while nitrogen and argon present fewer operational hazards.

- Match Production Scale: For large-scale production, prioritize nitrogen for cost efficiency. Opt for argon in smaller, specialized applications to ensure utmost purity.

Our engineers create custom gas solutions tailored to your specific needs. Our furnaces support precise control of hydrogen, nitrogen, or argon.

Why Choose CVSIC Atmosphere Furnaces?

CVSIC understands that protective gases are vital to your process. From design to production, we meet your exact requirements. Our furnaces meet the needs for hydrogen, nitrogen, or argon and come with full customization, helping to optimize process, cost, and efficiency.

Still unsure about selecting the right protective gas? Contact CVSIC’s engineering team! We’ll design the optimal atmosphere furnace solution tailored to your needs, making your production more efficient and worry-free.

FAQ

Is hydrogen safe in atmospheric furnaces?

While hydrogen is flammable, CVSIC furnaces incorporate multiple safety protections—including gas leak detection, automatic shut-off valves, and pressure relief devices—to ensure secure operation.

Can nitrogen and argon be mixed?

Yes, but precise mixing ratios based on process requirements are essential. CVSIC furnaces feature multi-gas mixing control that dynamically adjusts gas ratios in real-time, perfectly adapting to complex processes requiring mixed atmospheres.

Why is argon more expensive than nitrogen?

Argon offers superior chemical stability, but its production and purification costs are higher, making it an ideal choice for applications that demand extreme atmospheric purity.

How can I reduce protective gas usage costs?

Opt for economical gases (like nitrogen) or optimize gas flow control. CVSIC atmosphere furnaces feature an efficient gas management system that automatically adjusts flow rates according to process stages, thereby significantly reducing gas consumption.

What if my process requires specialty gases?

No worries! CVSIC supports customized atmosphere furnace designs compatible with various protective gases and mixed atmospheres. Contact us to discuss your specific requirements and ensure your equipment precisely matches your process needs!