High-Temperature Tube Furnaces: Energy-Saving Designs and Efficiency Tips from CVSIC

Many customers have shared a common concern: “My furnace reaches the desired temperature, but the electricity bill is skyrocketing.”

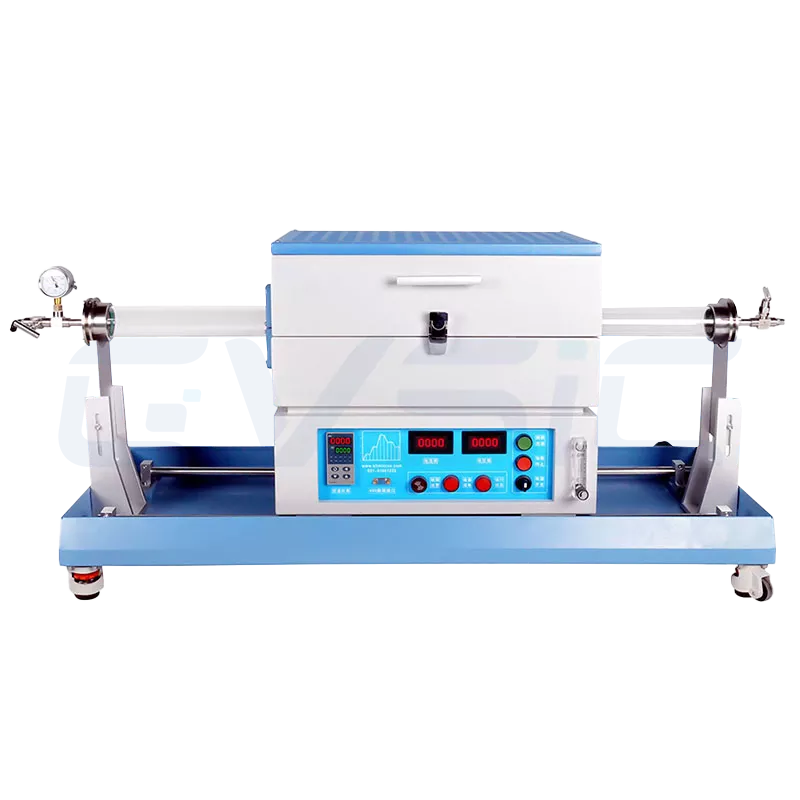

Operating high-temperature tube furnaces at 1200°C–1700°C demands energy to maintain stable zones. Yet, high consumption often results from design or usage issues, not process needs. CVSIC outlines the causes of high energy consumption in tube furnaces and provides practical solutions to enhance efficiency.

Why Do High-Temperature Tube Furnaces Consume So Much Energy?

High energy consumption in tube furnaces typically results from the following factors:

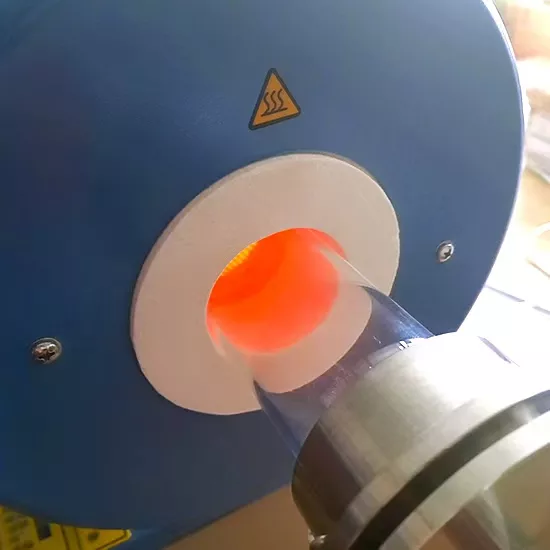

- High-temperature demands: Higher temperatures require more energy. For instance, heating to 1600°C consumes 30–50% more electricity than 1200°C.

- Poor insulation performance: Aging or inadequately designed insulation layers—such as those with insufficient thickness or made from less-effective insulation materials—lead to significant heat loss. Insulation layers are materials that slow heat transfer, keeping the high temperature inside the furnace.

- Inefficient operations: Frequent furnace door opening, rapid heating, or prolonged insulation periods waste electricity.

- Aging equipment: Degraded heating elements or temperature control systems reduce efficiency, leading to increased power consumption.

- Atmosphere or vacuum systems: Vacuum pumps and the use of high-purity gases add energy costs, particularly in extended experiments.

Now that we’ve identified the primary causes of high energy consumption, let’s examine how you can address them through smart design choices and improved operational practices.

Energy-Saving Design: Optimizing Equipment for Efficiency

At CVSIC, energy efficiency is achieved through comprehensive optimization of furnace structure, materials, and control systems:

High-performance insulation materials

- Utilize ceramic fiber or alumina fiber insulation with low thermal conductivity to minimize heat loss.Utilize graded insulation designs that strike a balance between high-temperature resistance and reduced thermal conductivity.

- Configure insulation thickness precisely for specific temperature ranges, avoiding a one-size-fits-all approach.

Optimized heating elements

- Deploy efficient molybdenum disilicide or silicon carbide heating elements.

- Strategically arrange silicon carbide or molybdenum disilicide elements to prevent localized overheating.

- Zone-specific temperature control prevents overheating and saves energy.

- Tailor power curves to match specific process requirements, rather than using a single power setting.

Multi-zone furnace design

- For experiments involving long furnace tubes, multi-zone furnaces enable targeted temperature control, preventing unnecessary overheating and resulting in significant energy savings.

Intelligent control systems

- Incorporate PID (Proportional-Integral-Derivative) controllers, which are automated control loops that reduce temperature fluctuations and help maintain setpoints accurately.

- Enable timed operation and programmed heating cycles to avoid prolonged empty furnace runs.

- Provide data logging and energy consumption analysis to identify and eliminate inefficiencies.

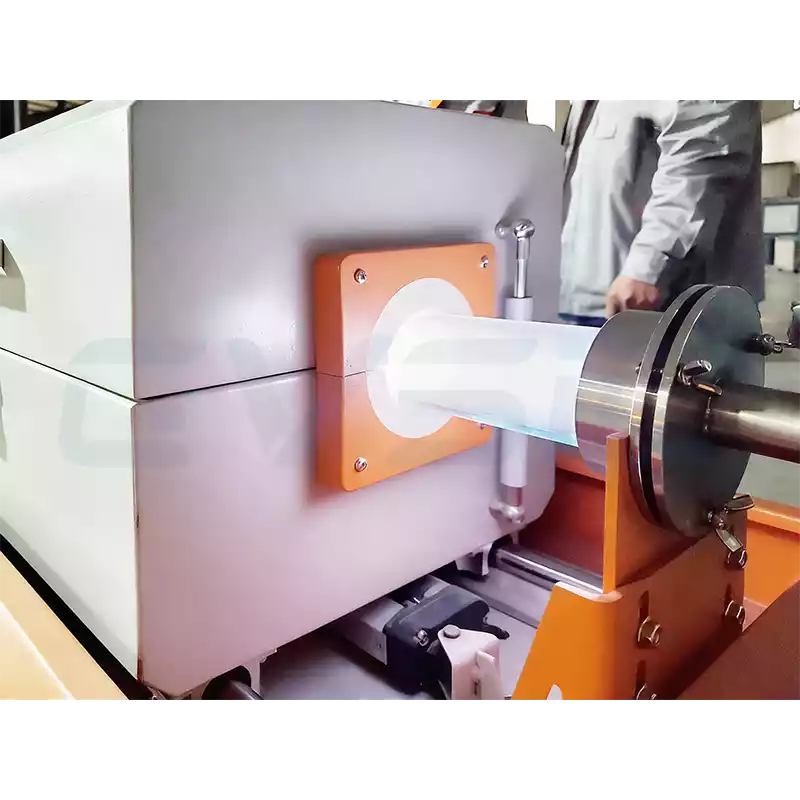

Enhanced sealing and atmosphere optimization

- Ensure robust furnace sealing to prevent heat loss through airflow.

- Optimize airflow control to reduce unnecessary gas heating, thereby enhancing efficiency.

Operational Tips: Small Changes, Significant Savings

Your operating habits play a critical role in energy efficiency. Adopt these practical techniques:

Plan efficient heating curves

- Avoid rapid heating, as it strains elements and increases energy consumption. Maintain a gradual 5–10°C per minute rate using CVSIC’s programmable controls.

- Use segmented insulation: Adjust temperatures based on process needs, maintaining high temperatures (e.g., 1600°C) only during critical phases and lowering to 800°C otherwise.

Optimize sample loading

- Load samples appropriately, keeping volumes at 50–70% of furnace tube capacity to avoid prolonged heating times.

- Place samples in the central heating zone to maximize heat efficiency and avoid losses in cooler end zones.

Minimize furnace door opening

Each opening causes heat loss, extending heating time by 5-10 minutes. Batch-load samples to reduce operation frequency.

Use atmosphere or vacuum systems wisely

- For atmosphere furnaces, use optimal gas flow rates to prevent waste. CVSIC furnaces feature flow meters for precise control.

- In vacuum furnaces, use high vacuum (such as 10^-3 Pa, meaning the pressure is 0.001 pascal) only when necessary; low vacuum (10^-1 Pa, or 0.1 pascal) suffices for many experiments, which reduces energy consumption by the vacuum pump.

Maintain equipment regularly

- Clean insulation layers to remove dust or contaminants that reduce efficiency.

- Replace heating elements every 2,000–3,000 hours to sustain performance.

- Calibrate thermocouples, which are temperature sensors, and PID controllers regularly to prevent energy waste from inaccurate temperature readings.

Match process requirements

- Select the lowest effective temperature for your experiment to minimize energy consumption.

Purchase high-performance tube furnaces from Chinese tube furnace manufacturer

Long-Term Energy Efficiency: Upgrades and Customization

For persistently high energy consumption, consider these advanced solutions:

- Upgrade to energy-efficient furnace models: CVSIC’s latest furnaces integrate advanced insulation and intelligent controls, offering a return on investment within 1–2 years.

- Customize furnace tube dimensions: Oversized or overly long tubes waste energy. CVSIC tailors tube sizes to your sample requirements, reducing unnecessary heating.

- Incorporate energy recovery systems: Select CVSIC high-end models feature heat recovery, repurposing residual heat to preheat gases or samples, achieving up to 10% energy savings.

CVSIC’s Recommendations

Many customers think high energy use is inevitable, but our experience proves otherwise. With structural optimization, intelligent controls, and proper usage, we’ve helped clients reduce energy use in 1600°C tube furnaces by over 20%, lowering costs and extending element life.

If high energy costs are a concern, consult CVSIC’s engineering team. We’ll develop tailored energy-saving strategies based on your specific experimental or production needs.

FAQ

What are the main sources of energy consumption in high-temperature tube furnaces?

Heating elements (60–70%), insulation heat loss (20–30%), and vacuum/atmosphere systems (10–20%). CVSIC’s energy-saving designs optimize these components for efficiency.

Can replacing heating elements reduce energy use?

To some extent, yes, but greater savings can be achieved by optimizing element arrangement and control strategies, rather than just material upgrades.

How do I know if my insulation layer needs to be replaced?

Excessive furnace shell heat or prolonged heating times may indicate insulation degradation.

Are there low-cost energy-saving methods for limited budgets?

Absolutely. Simple adjustments, such as minimizing empty furnace runs, controlling heating rates, and reducing door openings, can yield immediate savings.