In dental labs, furnaces are essential tools for creating restorations, with sintering and porcelain furnaces being the two most prevalent types. As an engineer, I frequently receive the question: “What are the precise differences between a sintering furnace and a porcelain furnace? Can they be used in place of each other?” Today, we will explore their differences to assist you in selecting the most appropriate equipment for your laboratory or clinic. Whether you’re producing durable zirconia crowns or carefully designing ceramic veneers, choosing the right furnace can significantly enhance your efficiency.

Core Differences Between Sintering Furnaces and Porcelain Furnaces

Although both fall under the category of dental furnaces, they exhibit significant variations in purpose, operating temperatures, processing workflows, and compatible materials. Here’s a detailed comparison:

Purpose and Processing Goals

Dental Sintering Furnace

- Goal: To achieve the best crystal structure in zirconia through high-temperature sintering, which improves strength, hardness, and translucency.

- Typical Output: Durable all-ceramic crowns and zirconia bridges.

- Main Use: Sintering durable materials like zirconia for creating all-ceramic crowns, bridges, or implant restorations.

- CVSIC Highlight: Our dental zirconia sintering furnace features intelligent temperature control technology that guarantees uniform sintering with a yield rate of up to 99%.

Dental Porcelain Furnace

- Main Use: Fires ceramic materials to apply aesthetic coatings or produce all-ceramic veneers, focusing on restorative aesthetics.

- Goal: To fire ceramic layers at lower temperatures for optimal bonding with substrates (such as metal or zirconia), resulting in naturally appealing finishes.

- Typical Output: Ceramic veneers, metal-ceramic crowns, and anterior aesthetic restorations.

- CVSIC Highlight: Our Dental porcelain furnaces facilitate vacuum firing to reduce bubbles and ensure impeccable aesthetics.

Tip: If your laboratory emphasizes high-strength restorations, sintering furnaces are the better choice; for aesthetic purposes, porcelain furnaces are more appropriate.

Working Temperature and Heating Characteristics

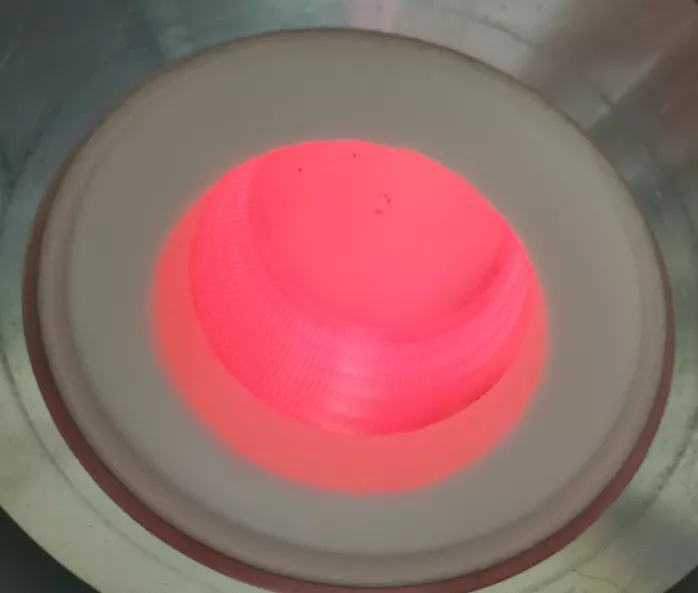

Sintering Furnaces

- Temperature Range: 1400°C to 1600°C, ideal for high-temperature sintering operations.

- Heating Characteristics: Requires prolonged, gradual heating and cooling profiles to avoid thermal stress cracking in zirconia materials.

- Process Requirements: Accurate temperature management and uniform heating are essential to prevent localized overheating or temperature fluctuations that could affect material properties.

Porcelain Kiln

- Temperature Range: 800°C to 1200°C, suitable for low-temperature ceramic processing.

- Heating Characteristics: Focuses on multiple programmed heating stages and rapid cooling, coupled with vacuum conditions to enhance ceramic layer adhesion and aesthetics.

- Process Requirements: Vacuum systems and quick-response temperature control mechanisms are crucial to achieve bubble-free, consistent ceramic firing.

CVSIC Recommendation: The high-temperature characteristics of sintering furnaces do not allow them to substitute for porcelain furnaces completely, and vice versa. The choice should rely on your primary processing material.

Applicable Materials

Sintering Furnace: Primarily used for zirconia, but also capable of handling certain high-melting-point materials (like specific metal alloys).

- Common Applications: All-ceramic crowns, zirconia bridges, and implant abutments.

- Material Characteristics: Zirconia needs high-temperature sintering to attain superior strength and translucency.

Porcelain Kiln: Mainly deals with ceramic materials, sometimes utilized for metal-ceramic techniques.

- Common Applications: Ceramic veneers, metal-ceramic crowns, and layered aesthetic restorations.

- Material Characteristics: Ceramics must be fired at lower temperatures to maintain color and texture.

Want to discover more about aligning dental materials with kiln types? Refer to our Dental Material Processing Guide!

Process Flow & Timing

Sintering Furnace

- Process: Comprises preheating, sintering, holding, and slow cooling—typically taking 6 to 8 hours altogether.

- Characteristics: A complex procedure that necessitates strict control over temperature ramps to safeguard materials.

- Applications: High-volume production of high-strength restorations.

Porcelain Furnace

- Process: Involves firing ceramic coatings, vacuum treatments, and rapid cooling, generally completed within 1 to 2 hours.

- Features: A quicker process suited for the rapid production of aesthetic restorations.

- Applications: Small-batch or custom aesthetic restorations.

CVSIC Tip: If your lab demands both efficiency and aesthetics, consider CVSIC’s multi-functional furnace models, which can easily switch between sintering and porcelain-firing modes, thus saving time and reducing equipment expenses.

Can sintering furnaces and porcelain furnaces be used interchangeably?

Answer: They are partially interchangeable, but not entirely substitutable.

- Some advanced multi-functional dental furnaces are capable of handling both sintering and porcelain processes, but specialized furnaces perform better in their particular roles. For instance, the high-temperature capabilities of a sintering furnace may hinder accurate temperature control during porcelain firing.

- The temperature limits of glazing furnaces are insufficient to meet the elevated temperature demands for zirconia sintering.

How to select the appropriate dental furnace for your needs?

Choosing between a sintering furnace and a glazing furnace is based on your laboratory’s requirements. Here are some practical suggestions:

- Determine your primary materials:

- Focused on zirconia? Opt for a sintering furnace.

- Concentrating on ceramic veneers or aesthetic restorations? Go for a porcelain furnace.

- Assess throughput and efficiency:

- Larger laboratories need high-capacity sintering furnaces

- Smaller clinics can choose compact porcelain furnaces or versatile multi-functional furnaces.

- Consider budget and space:

- Multi-functional furnaces are cost-effective and space-saving, perfect for small laboratories.

- Look at after-sales support:

- CVSIC offers 24/7 technical assistance and regular maintenance for stable long-term performance.

Still unsure? Our guide on choosing dental furnaces provides more comprehensive purchasing information!

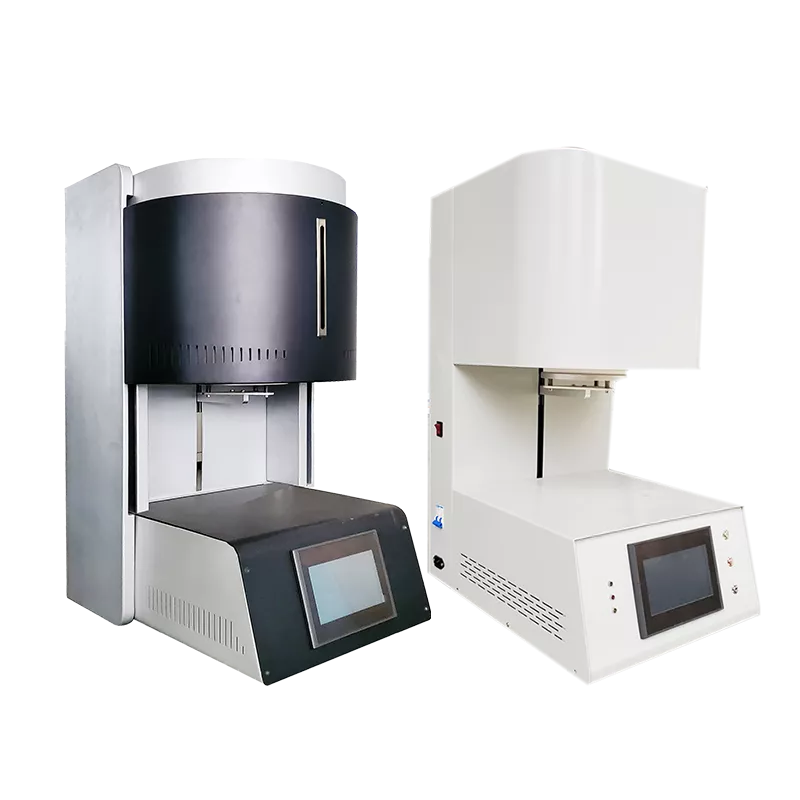

Why select CVSIC dental furnaces?

At CVSIC, we are dedicated to delivering high-performance, dependable furnace solutions for dental laboratories. Whether you need sintering or porcelain furnaces, our products provide the following benefits:

- Accurate Temperature Regulation: Guarantees consistent material processing with an impressive yield rate of up to 99%.

- Intuitive User Interface: The touchscreen operation is straightforward to use for both novices and experts.

- Longevity: High-quality heating elements and furnace chamber materials enhance the lifespan of the equipment.

- Worldwide Support: Our 24/7 after-sales service addresses any technical issues at any time.

Discover CVSIC’s range of dental furnaces today to identify the ideal sintering or porcelain furnace for your requirements!

Conclusion

Sintering furnaces and porcelain kilns each have their own unique strengths in different applications. Choosing the appropriate equipment greatly improves your dental laboratory’s productivity and the quality of the final product. CVSIC is dedicated to offering high-performance solutions for dental furnaces. Whether you are working with robust zirconia or beautiful ceramic veneers, we are here to meet your requirements. Interested in learning more? Check out our dental furnace or reach out to our technical team today!