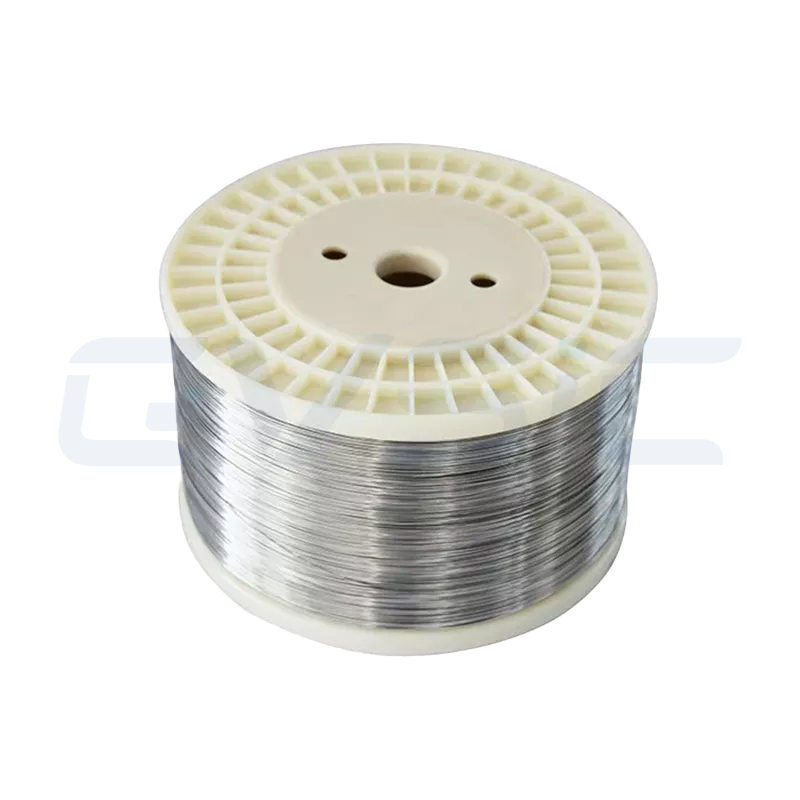

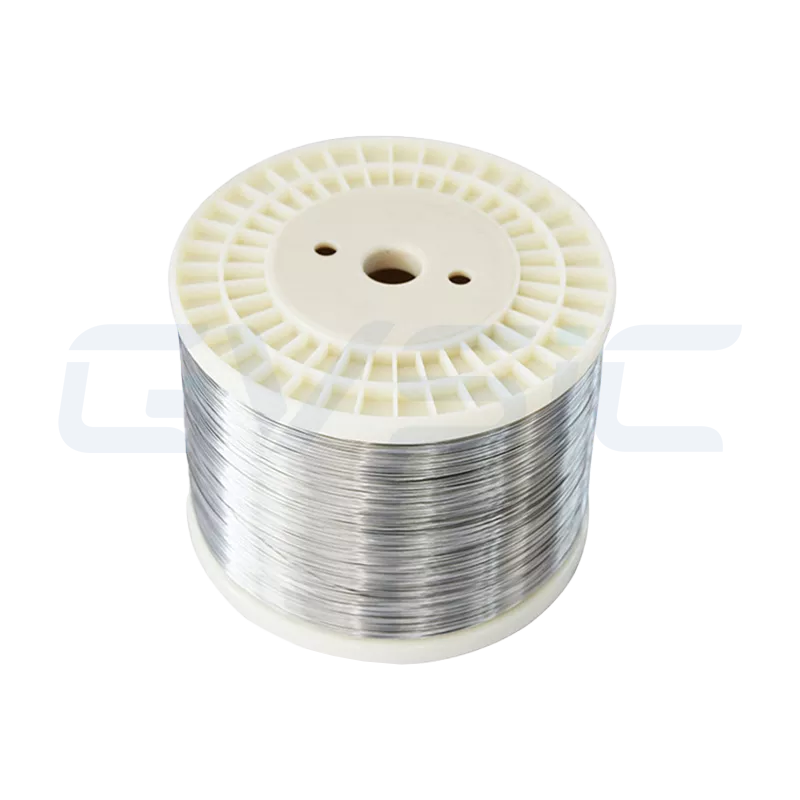

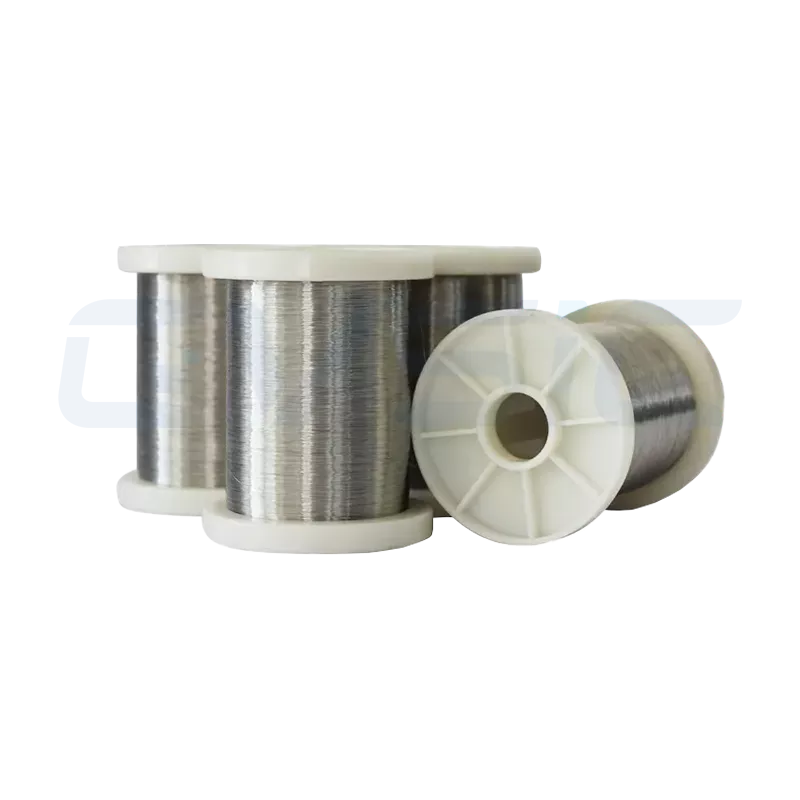

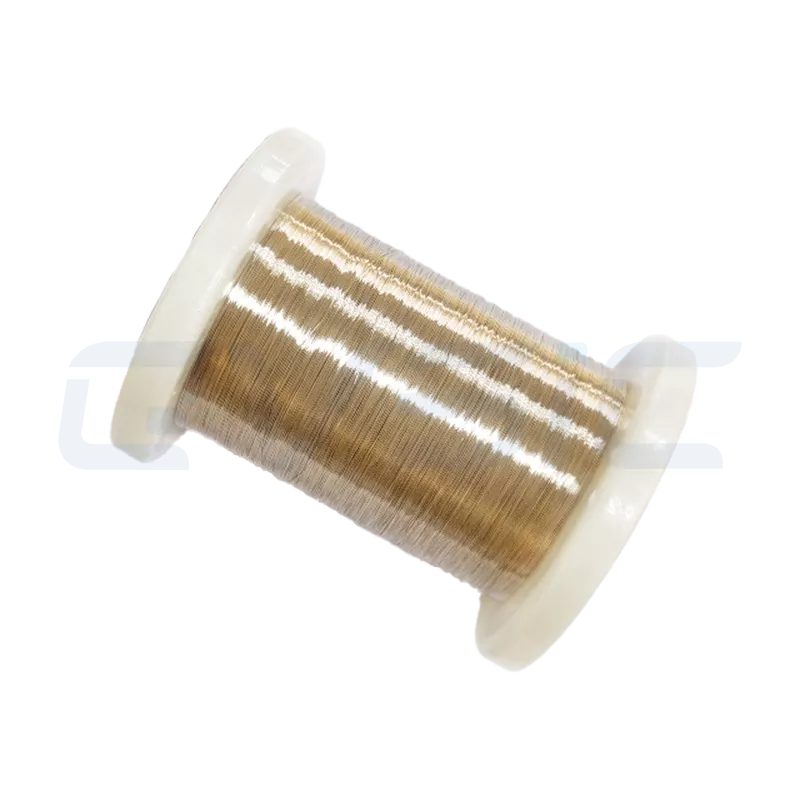

0Cr21Al6 Resistance Wire

0Cr21Al6 Alloy Wire

0Cr21Al6 is a solid FeCrAl high-temp resistance alloy with steady resistivity and great oxidation resistance—perfect for industrial electric heating in air up to around 1300°C.

- Model: CV-0Cr21Al6

- Alloy Grade: 0Cr21Al6 (FeCrAl 216)

- Main Composition: Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5

- Max Temp: 1250–1300°C

- Resistivity (20°C): 1.35 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6 is an iron-chrome-aluminum (Fe-Cr-Al) based FeCrAl high-temperature resistance alloy that’s super common in industrial electric heating setups.

Thanks to steady resistance, killer oxidation resistance, and reliable performance at high heat, it’s a go-to material for 1300°C-level industrial heating jobs.

Key Features of 0Cr21Al6 High-Aluminum FeCrAl Alloy

By bumping up the aluminum to around 6%, 0Cr21Al6 gets way better at fighting oxidation in hot air.

- Aluminum ≈6% means a tighter, stickier oxide layer—perfect for furnaces running in plain air (not vacuum or shielded gas).

- Higher resistivity (about 1.45 μΩ·m) packs more power into the same length—great for compact designs.

- Best for steady runs at 1200–1250°C; can hit 1300°C short-term, but don’t push it every day.

- Downside: Trickier to work cold—can crack when coiling, so it usually needs annealing.

The big win with 0Cr21Al6 is rock-solid oxidation resistance in high-temp air.

Composition & Basic Specs

| Item | Parameter |

|---|---|

| Alloy Grade | 0Cr21Al6 (FeCrAl 216) |

| Main Chemical Composition (%) | Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5 |

| Max Continuous Temp | 1250–1300°C |

| Resistivity (20°C) | 1.35 μΩ·m |

| Density | 7.1 g/cm³ |

| Thermal Conductivity | 16 KJ/m·h·°C |

| Expansion Coefficient | 14 ×10⁻⁶/°C |

| Melting Range | 1500–1520°C |

| Tensile Strength | ≥650 MPa (wire) |

| Elongation | ≥15% |

| Microstructure | Ferritic |

| Magnetic | Yes |

| Key Features | Top-notch oxidation resistance, perfect for high-temp furnaces, long-lasting, and budget-friendly |

| Common Uses | Heating tubes, ovens, space heaters, humidifiers, dryers |

How It Handles High Temps & Oxidation

In hot air, the aluminum on the surface reacts with oxygen to build a dense, solid Al₂O₃ protective layer.

This layer:

- Keeps extra oxygen from sneaking in deeper

- Slows down ongoing oxidation

- Boosts stability at high heat

- Makes heating elements last way longer

That’s why 0Cr21Al6 shines in electric heating that stays exposed to air long-term.

Temp Ratings & Use Range

| Spec | Details |

|---|---|

| Recommended Long-Term Temp | ≤ 1300°C |

| Short-Term Max | Up to 1350°C (depends on wire size and load) |

| Heating Style | Resistive |

| Heat Stability | Holds structure well at high temps |

With smart power loading and design, 0Cr21Al6 gives steady, predictable performance at high heat.

Where It Gets Used

You’ll find 0Cr21Al6 in all sorts of industrial and lab spots:

- Heating wires in industrial resistance furnaces

- Box furnaces and lab furnaces

- High-temp air heaters

- Ceramic, glass, and heat treatment gear

- Research and lab heating systems

Usage Tips & Limits

Long-term continuous temp ≤ 1250–1300°C

- Go over that too often and the oxide layer grows way faster

- Long runs past the limit thin out the wire and shift resistance more

Skip strongly reducing or sulfur-heavy air

- Stuff like H₂, CO, or sulfides wreck the protective alumina

- Life drops big time in those setups

Wire size sets your temp ceiling

- Thin wires (≤0.5 mm) overheat easier at high loads

- Always calc max surface load (W/cm²) from the diameter

Don’t stress it mechanically when hot

- It gets less ductile at temp

- Avoid tension or vibes during operation

Its reliability and flexibility make it a solid pick for mid-to-high temp industrial heating.

Practical Engineering Perks

- Steady resistance makes power math easy

- Oxidation resistance fits air environments perfect

- Works with all kinds of element shapes

- Decent to form and coil

- Not for heavy reducing or sulfur air

Design & Selection Tips

When building with 0Cr21Al6, zero in on:

- Matching diameter to surface load

- Picking a safe long-term temp

- Good supports with room for expansion

- Making sure the air is oxidizing enough

Nail the structure and power, and you’ll get the most out of this alloy.

Supply Options & Custom Work

We offer:

- Bunch of wire diameters

- Custom lengths and resistance

- Big industrial batches

- Tech specs and selection help

Great for equipment makers, furnace builders, and system integrators.

0Cr21Al6 is a solid FeCrAl high-temp resistance alloy with steady resistivity and great oxidation resistance—perfect for industrial electric heating in air up to around 1300°C.

FAQs | Common Questions

What atmospheres work best?

Mainly plain air or mildly oxidizing—not good for strong reducing or sulfur stuff.

Recommended temp?

Keep long-term under 1300°C; short bursts can go higher depending on your setup.

Custom diameters and resistance?

Yeah, we can tailor to your voltage, power, and design needs.

Good for non-stop running?

Totally—handles continuous high heat when designed right.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 0Cr21Al6 Resistance Wire

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support