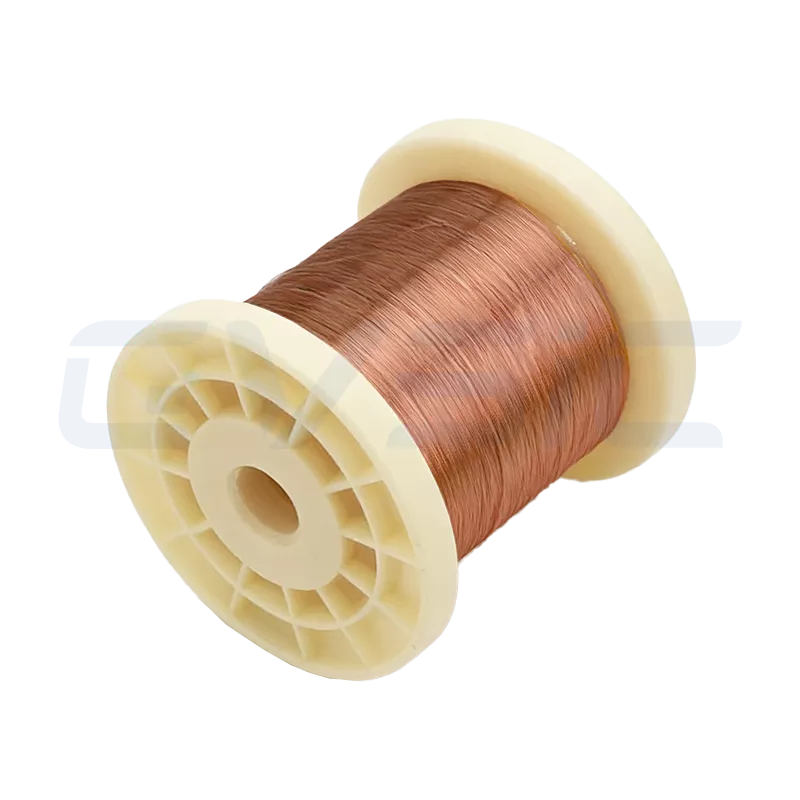

0Cr21Al6Nb Resistance Wire Kanthal A1 Alternative

Kanthal A1 Alternative

0Cr21Al6Nb is an Nb-stabilized FeCrAl resistance wire that’s killer for 1350°C industrial electric heating. It’s a solid, cheaper swap for Kanthal A1. We handle custom orders and wholesale at CVSIC.

- Model: CV-0Cr21Al6Nb

- Alloy Grade: Fe–Cr–Al–Nb resistance alloy

- Main Composition: Fe: Bal., Cr ≈21%, Al ≈6%, Nb (trace)

- Max Temp: ≤ 1350°C

- Resistivity (20°C): 1.45 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr21Al6Nb is an Nb (niobium)-stabilized FeCrAl resistance wire. It tosses in a bit of Nb to the classic iron-chrome-aluminum mix to stop grains from growing and boost stability at high temps.

It beats regular 0Cr21Al6 hands down in high-temp strength, creep resistance, and overall structure—it’s one of the best domestic FeCrAl options that comes closest to matching Kanthal A1 performance.

In hot air setups, it’s a go-to for 1350°C industrial electric heating, especially when you need serious lifespan and rock-solid reliability.

Standout Features of 0Cr21Al6Nb

0Cr21Al6Nb takes 0Cr21Al6 and adds a dash of niobium—that’s the game-changer. What Nb brings to the table:

- Keeps grains from getting too big at high heat, so it doesn’t turn brittle and weak.

- Way better at fighting creep—elements won’t sag or warp under long, hot loads.

- Tougher oxide layer means more consistent life—awesome for lines that run non-stop for years without shutdowns.

- Costs a bit more than standard high-aluminum stuff, but it saves big on maintenance and downtime.

The real selling point? Super stable performance during long hauls at high temps.

Key Specs for 0Cr21Al6Nb

| Parameter | Value |

|---|---|

| Alloy Grade | 0Cr21Al6 (FeCrAl 216) |

| Main Chemical Composition (%) | Fe: Balance; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5 |

| Maximum Continuous Operating Temperature | 1250–1300°C |

| Electrical Resistivity (20°C) | 1.35 μΩ·m |

| Density | 7.1 g/cm³ |

| Thermal Conductivity | 16 KJ/m·h·°C |

| Linear Expansion Coefficient | 14 × 10⁻⁶/°C |

| Melting Point Range | 1500–1520°C |

| Tensile Strength | ≥650 MPa (wire) |

| Elongation | ≥15% |

| Microstructure | Ferritic |

| Magnetic Properties | Magnetic |

| Material Features | Extremely strong oxidation resistance, suitable for high-temperature furnaces, long service life, cost-effective |

| Typical Applications | Electric heating tubes, ovens, heaters, humidifying furnaces, drying furnaces |

Nb forms stable stuff or strengthens the mix, slowing down grain growth and brittleness—big boost to heating element life.

Where 0Cr21Al6Nb Shines

0Cr21Al6Nb resistance wire is perfect for industrial heating that demands top-tier life and stability:

- Always-on industrial electric furnaces Runs hot long-term as heating elements, cutting down on breaks and deformation.

- High-temp heat treatment furnaces Nb stability handles frequent heat-up/cool-down cycles.

- Ceramic sintering and powder metallurgy kilns Great oxidation resistance + steady power.

- Premium lab and test furnaces Spots needing tight temp control and long runs.

Usage Tips & Limits

Long-term temp ≤ 1350°C

- Push higher and you’ll need to drop surface load a lot

Still steer clear of reducing air

- Nb doesn’t fix the Al₂O₃ layer’s weakness there

0Cr21Al6Nb vs Kanthal A1

| Feature | 0Cr21Al6Nb | Kanthal A1 |

|---|---|---|

| Alloy | FeCrAl + Nb | FeCrAl |

| Max Temp | ~1350°C | ~1400°C |

| Oxidation | Top-Notch | Top-Notch |

| Creep Resistance | Strong (Nb boost) | Elite |

| Life | Long | Extra Long |

| Cost | Way lower | Premium |

| Best For | High value swap | Original top-tier |

0Cr21Al6Nb is a legit replacement for Kanthal A1 If you’re running steady near 1400°C, Kanthal A1 or 0Cr27Al7Mo2 might be safer.

Specs & Custom Options | B2B Supply

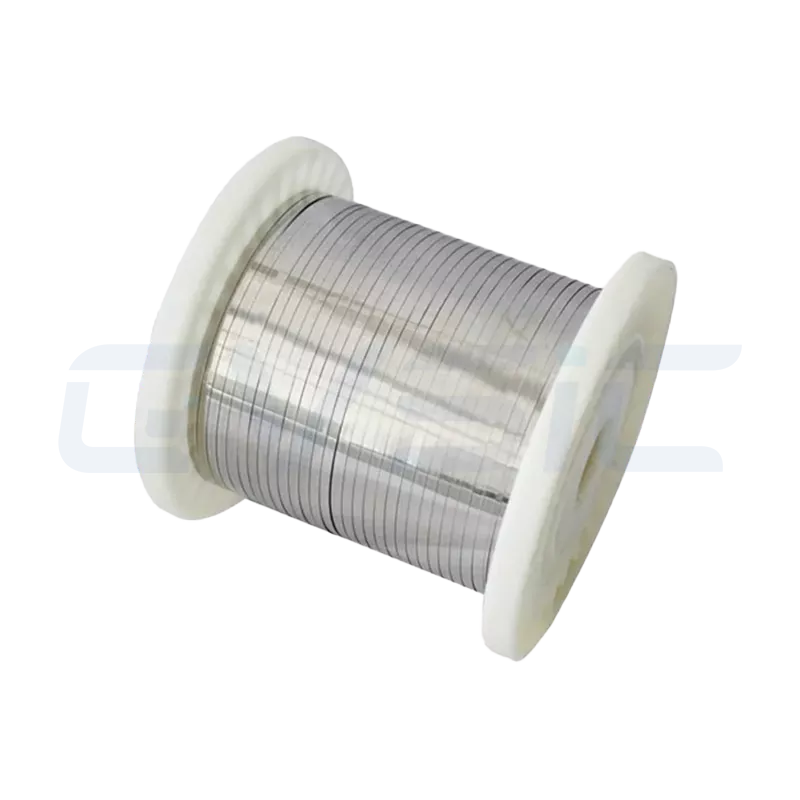

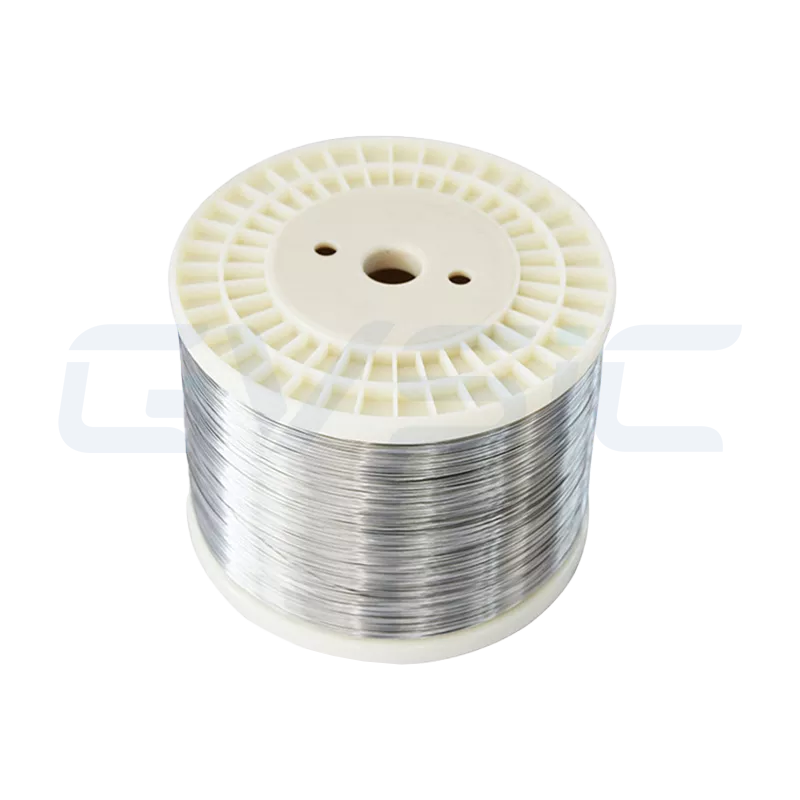

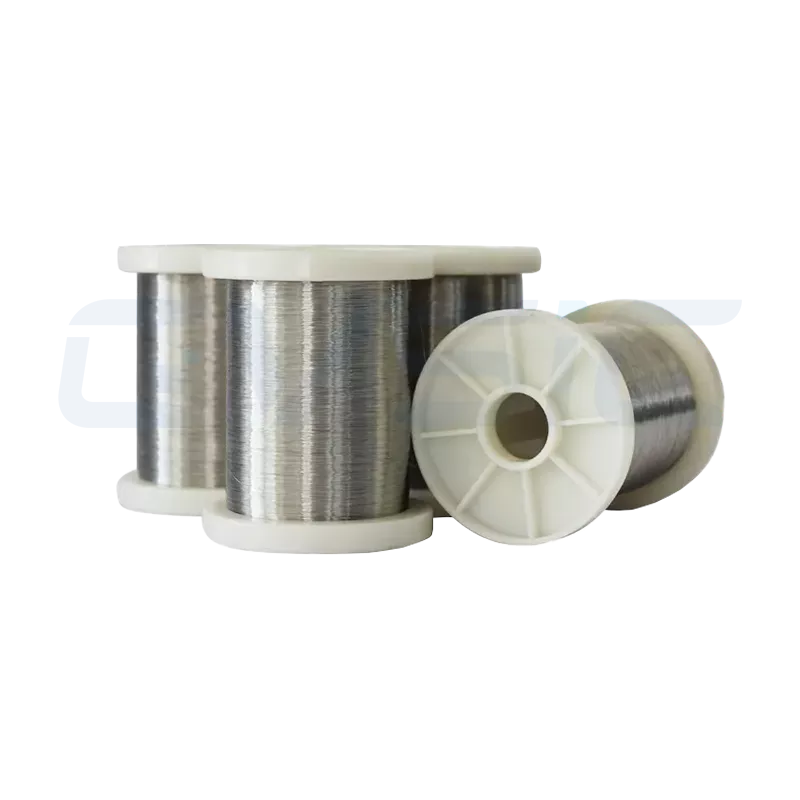

We cover full customization and wholesale for 0Cr21Al6Nb FeCrAl resistance wire:

- Diameters: Tons of specs

- Forms: Straight, coiled, pre-formed

- Surface: Bright or pre-oxidized

- Processing: Cut-to-length, coiling/shaping

- Models: Wholesale, OEM, ODM

We make sure 0Cr21Al6Nb holds up steady long-term in real jobs.

Wrap-Up | FeCrAl for High-Reliability Heating

0Cr21Al6Nb FeCrAl resistance wire, with that Nb stabilization, blows regular FeCrAl out of the water on high-heat strength, lifespan, and reliability—it’s a top pick for serious industrial heating systems.

Hit us up for specs, samples, or help picking the right one.

FAQs | 0Cr21Al6Nb Basics

What’s Nb for in 0Cr21Al6Nb?

Niobium stabilizes grains, bumping up creep resistance and lifespan at high heat.

Can it fully swap for Kanthal A1?

Yeah for most jobs under 1350°C in air; closer to 1400°C, check your setup.

How’s it better than plain 0Cr21Al6?

The Nb tweak gives it way better high-temp strength, creep fight, and long-term reliability—ideal for premium industrial stuff.

Good for 24/7 furnace runs?

Absolutely—built for continuous or super-reliable systems.

Custom and bulk available?

You bet—custom sizes, wholesale, OEM/ODM ready.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 0Cr21Al6Nb Resistance Wire Kanthal A1 Alternative

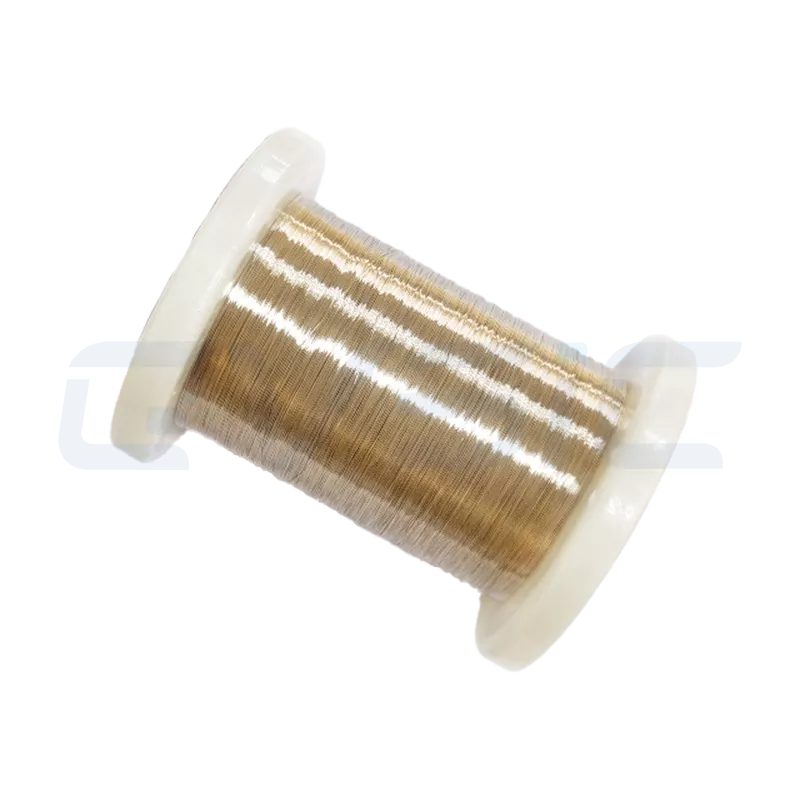

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support