0Cr23Al5 Alloy Wire

0Cr23Al5 Resistance Heating Wire

0Cr23Al5 is a go-to FeCrAl resistance wire with strong high-temp oxidation resistance and steady resistivity. It’s everywhere in industrial furnaces, electric heaters, and heat treatment setups. We offer custom specs, wholesale, and OEM support.

- Model: CV-0Cr23Al5

- Alloy Grade: 0Cr23Al5 (FeCrAl 235)

- Main Composition: Fe: Bal.; Cr: 22–24; Al: 4.5–6.0; Mo: ≤0.5

- Max Temp: 1250°C

- Resistivity (20°C): 1.40 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Tensile Strength: Tensile Strength ≥650 MPa

0Cr23Al5 is a classic FeCrAl (iron-chrome-aluminum) resistance wire, made mostly of iron (Fe), about 23% chromium (Cr), and 5% aluminum (Al).

At high temps, it builds a tight Al₂O₃ protective oxide layer that gives solid oxidation resistance and stable electrical behavior in regular air.

It’s a common pick for medium-to-high temp industrial heating and often steps in as a cost-effective alternative to 0Cr25Al5.

Standout Features of 0Cr23Al5

0Cr23Al5 is hands-down one of the most popular FeCrAl grades out there. That 23% Cr + 5% Al mix gives you solid high-heat performance at a really fair price.

- Runs steady long-term at 1150°C and can handle short spikes up to 1200°C no sweat.

- Enough aluminum to form a dense, continuous alumina layer that actually heals itself—stands up to tons of heating-cooling cycles without peeling off.

- Resistance stays super consistent with predictable temp changes—ideal for always-on setups and tight power control.

- Good high-temp strength plus easy workability—way simpler to coil and shape than super-high-aluminum grades like 0Cr27Al7Mo2, perfect for standard wires and coiled heaters.

- Built for long-haul heating designs—in steady conditions, it barely changes size or drifts in resistance, so lifespan is easy to predict.

Balanced, widely used, and super easy to swap in—0Cr23Al5 is the default choice for most industrial furnaces.

0Cr23Al5 (FeCrAl 235) Detailed Specs

| Item | Value |

|---|---|

| Model | CV-0Cr23Al5 |

| Alloy Grade | 0Cr23Al5 (FeCrAl 235) |

| Composition (%) | Fe: Bal.; Cr: 22–24; Al: 4.5–6.0; Mo: ≤0.5 |

| Max Continuous Temp | ≤ 1250°C |

| Resistivity (20°C) | 1.40 μΩ·m |

| Density | 7.1 g/cm³ |

| Thermal Conductivity | 13 KJ/m·h·°C |

| Expansion Coefficient | 14 ×10⁻⁶/°C |

| Melting Range | 1500–1520°C |

| Tensile Strength | ≥650 MPa |

| Elongation | ≥12% |

| Microstructure | Ferritic |

| Magnetic | Yes |

| Key Advantages | High Cr → Better oxidation & sulfur resistance |

| Common Uses | Industrial furnaces, resistance ribbons, tunnel kilns, sintering furnaces |

Its steady resistivity and high-temp strength make 0Cr23Al5 perfect for non-stop or on-off heating systems—long life without breaking the bank.

Where 0Cr23Al5 Gets Used

0Cr23Al5 resistance wire turns electricity into heat and shows up all over industrial heating gear:

- Industrial electric furnaces: Heating elements in box furnaces, trolley furnaces, and lab furnaces for high-heat work.

- Heat treatment setups: Great for annealing, tempering, normalizing—keeps temps even.

- Electric heater manufacturing: Tubular heaters, ceramic-supported elements.

- Lab and research gear: Test furnaces and experimental heating systems.

Usage Tips & Limits

Long-term continuous temp ≤ 1200–1250°C

- Short bursts can go higher

- Stay over that too long and the oxide gets thick and flakes off quicker

Match power load carefully to wire size

- Thinner wires in hot zones fail faster if surface load is too high

- Always calculate max W/cm² during design

Only good in oxidizing or neutral air

- Reducing gases (H₂, CO) or sulfur kills the protective layer

- Skip it for carburizing or sulfur-heavy furnaces

Don’t clamp it tight when hot

- Strength drops at temp—leave room for expansion to avoid snapping

Avoid super-fast hot-cold cycles

- Thermal shock weakens the oxide bond

- For frequent on-off, drop the design temp and load

0Cr23Al5 vs 0Cr25Al5 Quick Comparison

| Feature | 0Cr23Al5 | 0Cr25Al5 |

|---|---|---|

| Chromium | Lower | Higher |

| Aluminum | Steady | A bit higher |

| Max Temp | ~1250°C | ~1300°C |

| Cost | Lower | Higher |

| Best For | Mid-high temp heating | Pushing higher temps |

Quick tip:

- Temps ≤1250°C and want best bang for buck → Go 0Cr23Al5

- Need max surface heat or longest life → Step up to 0Cr25Al5

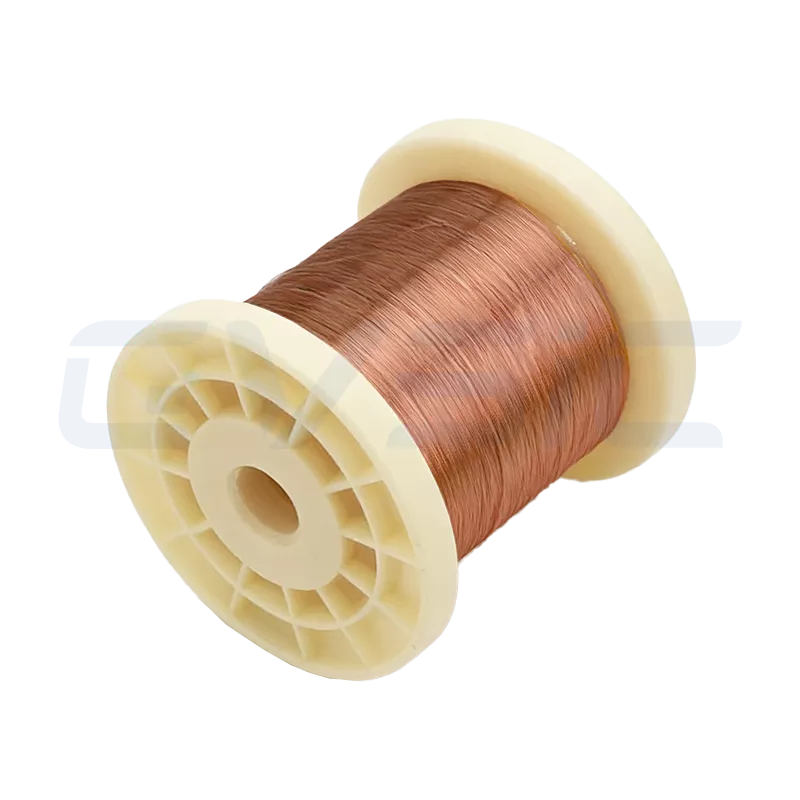

CVISC 0Cr23Al5 B2B Wholesale & OEM

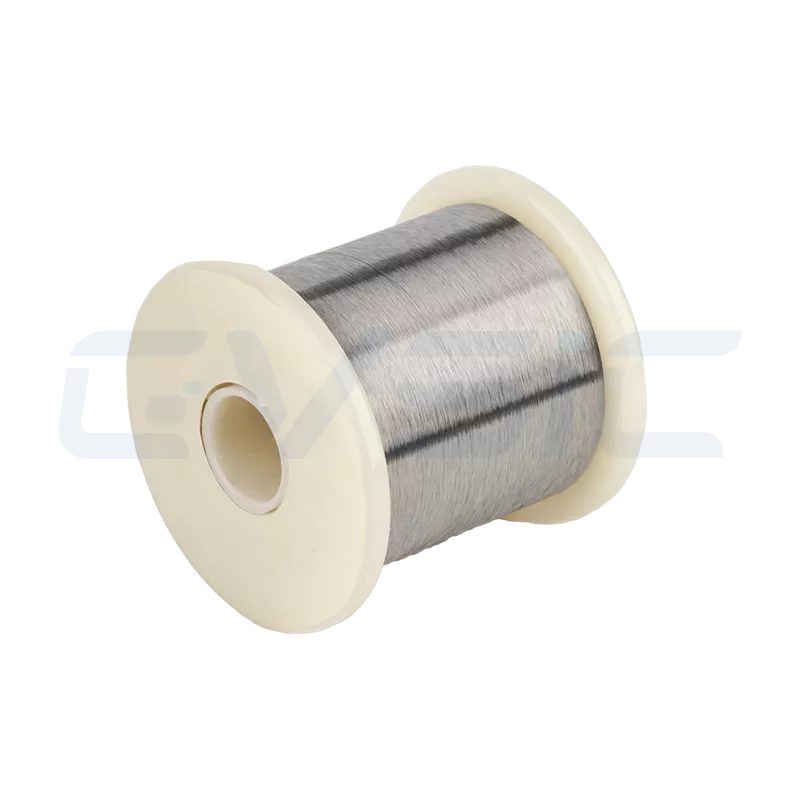

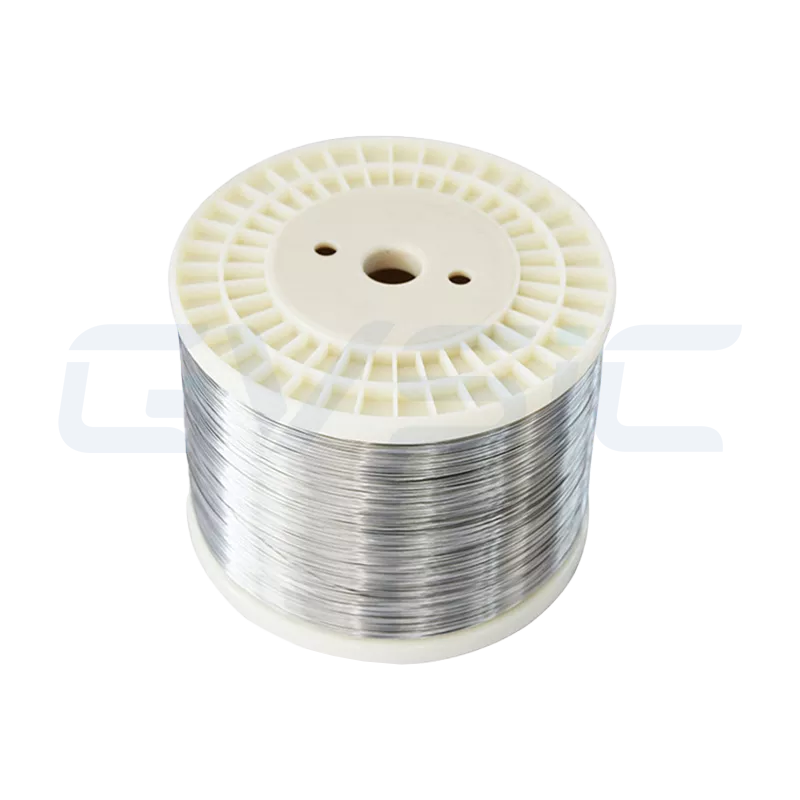

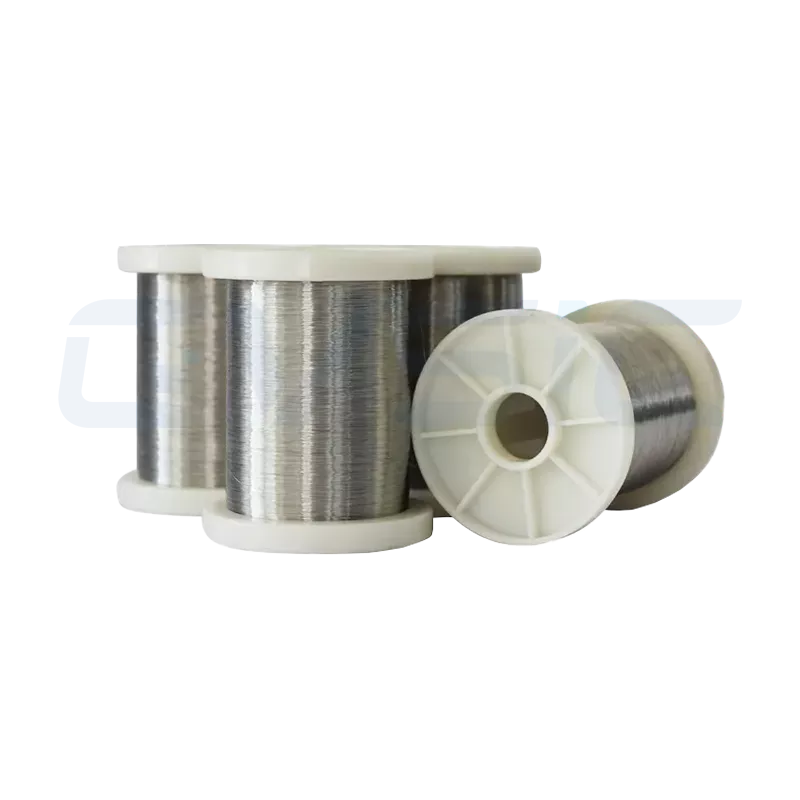

We handle full customization for 0Cr23Al5 FeCrAl resistance wire:

- Diameters: Wide range available

- Forms: Straight, coiled, cut-to-length

- Surface: Bright or pre-oxidized

- Packaging: Industrial spools or custom

- Orders: Wholesale, OEM, ODM

Perfect for heater manufacturers, furnace builders, and project buyers.

Quality & Supply Assurance | B2B Level

- Tight chemistry control

- Batch-to-batch resistivity consistency

- Proven FeCrAl production know-how

- Full testing reports and tech docs available

Every spool performs reliably with predictable life in real jobs.

Wrap-Up | Solid, Practical FeCrAl Resistance Wire

0Cr23Al5 FeCrAl resistance wire nails the balance of performance, price, and dependability—it’s a proven, reliable pick for industrial heating and resistive systems.

Reach out to our engineering team for specs, samples, or custom pricing.

FAQs | 0Cr23Al5 Basics

Is 0Cr23Al5 the same thing as FeCrAl?

0Cr23Al5 is a specific grade inside the FeCrAl family of resistance wires.

What’s the max temp it can take?

In air, aim for around 1250°C max—depends on wire size and load.

Can it replace 0Cr25Al5?

Yeah for mid-high temps, but if you’re pushing close to 1300°C, stick with 0Cr25Al5.

Good for non-stop running?

Totally—great long-term stability when atmosphere and load are dialed in right.

Custom and bulk orders available?

Yes—we do custom sizes, wholesale, and OEM for B2B long-term partnerships.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 0Cr23Al5 Alloy Wire

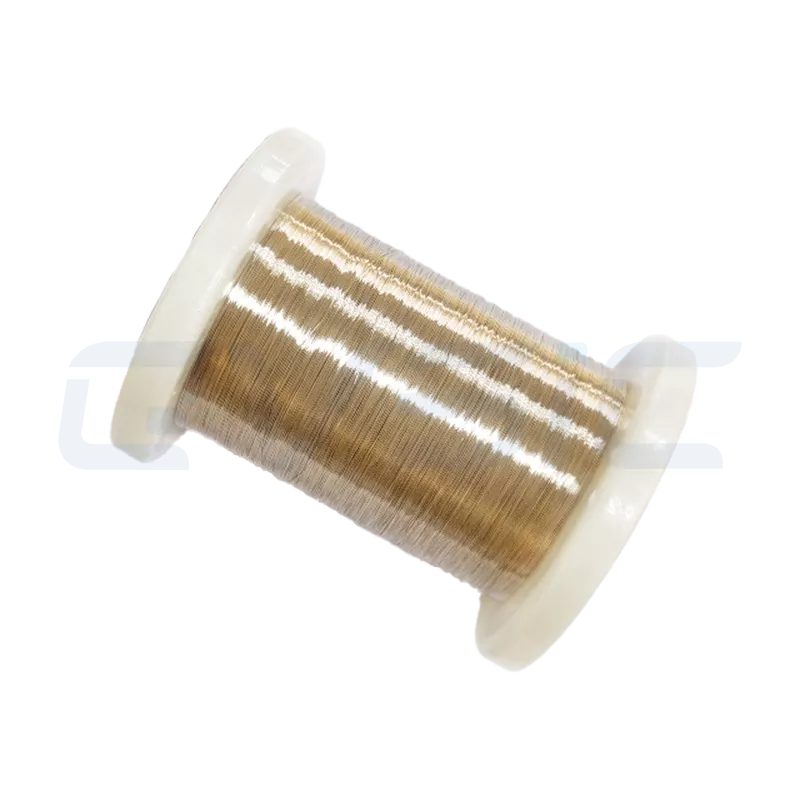

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support