0Cr27Al7Mo2 Wire Kanthal APM Alternative

Kanthal APM Alternative

0Cr27Al7Mo2 is a Mo-strengthened FeCrAl resistance wire built for 1400°C industrial heat—it’s a spot-on, cheaper swap for Kanthal APM. Killer oxidation resistance, high-temp strength, and rock-solid long-term stability. We do custom and wholesale.

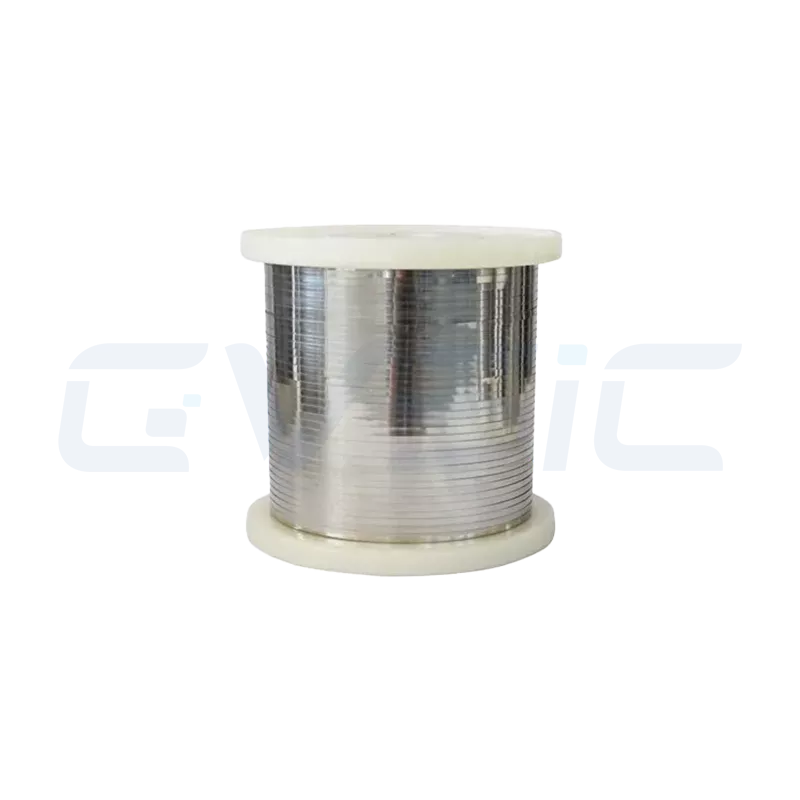

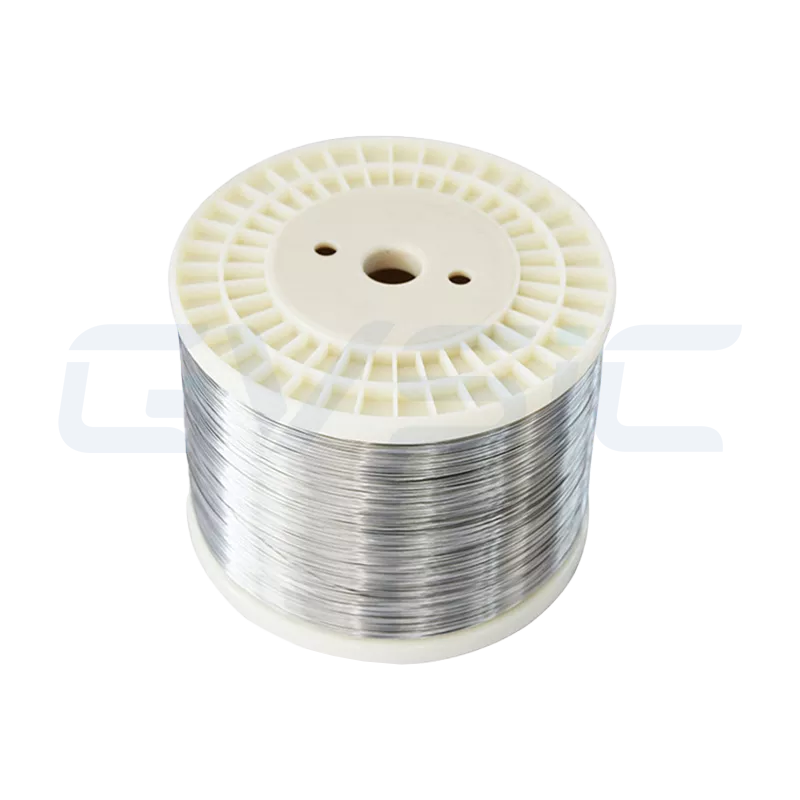

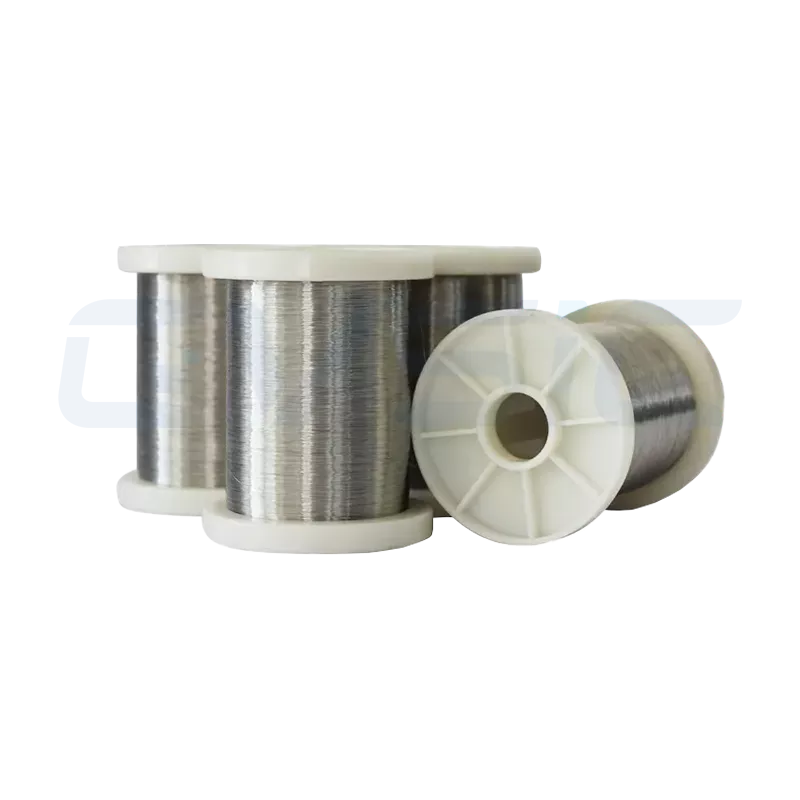

- Model: CV-0Cr27Al7Mo2

- Alloy Grade: Fe–Cr–Al–Mo high-temp resistance alloy

- Main Composition: Fe: Bal., Cr ≈27%, Al ≈7%, Mo (trace)

- Max Temp: ≤ 1400°C

- Resistivity (20°C): 1.50 μΩ·m

- Density: 7.1 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

0Cr27Al7Mo2 is a molybdenum (Mo)-strengthened FeCrAl (iron-chrome-aluminum) resistance wire. It packs high chromium (≈27%) and high aluminum (≈7%), plus Mo to crank up high-temp strength, oxidation resistance, and corrosion fight.

It hits the peak for Chinese FeCrAl in oxidation resistance, high-heat strength, creep resistance, and staying put dimension-wise—super close to Kanthal APM performance.

This is a top-shelf FeCrAl grade that handles up to 1400°C, made for brutal high-temp industrial gigs.

Standout Features of 0Cr27Al7Mo2 Ultra-High-Temp Alloy

0Cr27Al7Mo2 is the most loaded-up alloy in the FeCrAl crew, getting its power from multi-element teamwork.

It’s the heaviest-alloyed in FeCrAl: 27% Cr, 7% Al, and molybdenum (Mo)—triple boost.

- Super tough against oxidation—runs steady long-term at 1300°C and handles quick hits to 1400°C.

- Mo ramps up high-temp strength and creep resistance big time—elements barely sag or warp when hot.

- Resistance and structure are dialed to max—perfect for tough stuff like premium ceramic sintering, single crystal growth, and aerospace heat treating.

- Heads up on downsides: All that alloying makes it brittler cold (especially after chilling long in 600–900°C where brittle phases pop up), and it’s spendy with longer lead times.

0Cr27Al7Mo2 is built for 1400°C long-haul runs in FeCrAl.

0Cr27Al7Mo2 Detailed Specs Table

| Item | Value |

|---|---|

| Model | CV-0Cr27Al7Mo2 |

| Alloy Grade | 0Cr27Al7Mo2 (FeCrAl premium Mo alloy) |

| Composition (%) | Fe: Bal.; Cr: 26–28; Al: 6–8; Mo: 1.8–2.2 |

| Max Continuous Temp | 1450°C (top in FeCrAl series) |

| Resistivity (20°C) | 1.50 μΩ·m |

| Density | 7.1 g/cm³ |

| Thermal Conductivity | 11–12 KJ/m·h·°C |

| Expansion Coefficient | 14 ×10⁻⁶/°C |

| Melting Range | 1520–1540°C |

| Tensile Strength | ≥700 MPa |

| Elongation | ≥8% |

| Microstructure | Ferritic |

| Magnetic | Yes |

| Key Traits | Ultra oxidation/corrosion/sulfidation resistance; best creep fight at high temps |

| Common Uses | Ultra-high-temp industrial furnaces, powder metallurgy kilns, petrochemical gear, resistance heaters |

Where 0Cr27Al7Mo2 Gets Used

0Cr27Al7Mo2 resistance wire shines in extreme heat and tough spots:

- Ultra-high-temp industrial electric furnaces: Heating elements in sintering, heat treatment, and powder metallurgy setups.

- Continuous high-heat systems: Mo boost cuts creep and breakage risks.

- Corrosive industrial furnaces: High Cr + Al + Mo team up for better oxidation and corrosion resistance.

- Premium lab furnaces and R&D gear: Nails high stability and consistent life.

Usage Tips & Limits

Max continuous temp ≤ 1400°C

- Pushing limits—keep power density tight

Trickier to process and coil

- Brittler from high aluminum

- Best to form when annealed

Factor in thermal expansion in designs

- Big size shifts when hot

- Leave room to expand or risk failures

CVSIC 0Cr27Al7Mo2 vs Kanthal A1 / APM

| Feature | 0Cr27Al7Mo2 | Kanthal A1 | Kanthal APM |

|---|---|---|---|

| Process | Melted FeCrAl + Mo | Melted FeCrAl | Powder metallurgy FeCrAl |

| Max Temp | ~1400°C | ~1400°C | ~1400°C |

| Oxidation | Top-Notch | Top-Notch | Top-Notch |

| Creep Resistance | Top-Notch | Strong | Top-Notch |

| Dimensional Stability | Super High | High | Elite |

| Cost | Way lower than APM | High | Premium |

| Best For | Premium local swap | Standard original | Ultimate top-tier |

Quick picks: Go 0Cr27Al7Mo2 when

- Steady temps ≥1350°C

- Want near-APM stability

- Non-stop runs super sensitive to sag

- Cutting costs without big hits to performance

For swapping imported Kanthal APM, this is a prime choice.

Specs & Custom Options | B2B Supply

We handle full custom and wholesale for 0Cr27Al7Mo2 FeCrAl resistance wire:

- Diameters: Wide custom range

- Forms: Straight, coiled, pre-formed heaters

- Surface: Bright or pre-oxidized

- Processing: Cut-to-length, coiling, custom shapes

- Models: Wholesale, OEM, ODM

Great for furnace makers, high-end equipment builders, and big projects.

Wrap-Up | FeCrAl’s Ultra-High-Temp Champ

0Cr27Al7Mo2 FeCrAl resistance wire is the top-dog in FeCrAl for ultra-high temps and high-reliability gigs—perfect for industrial heating needing max life, stability, and safety.

Reach out for specs, samples, or selection help.

FAQs | 0Cr27Al7Mo2 Basics

Can it fully replace Kanthal APM?

Super close in most 1400°C air jobs, but APM edges out on insane lifespan and stability.

What’s Mo for?

Mo cranks high-temp strength, creep resistance, and corrosion fight.

Better than 0Cr21Al6Nb how?

Higher Cr, Al, and Mo—handles hotter and tougher spots.

Good for big heating elements?

Yeah—Mo makes large ones way better at fighting sag.

Built for continuous heavy loads?

Totally—kills it in high-load non-stop runs.

Okay in corrosive air?

Better than regular FeCrAl at high-temp corrosion, but check your specific setup.

Custom and bulk?

You bet—custom sizes, wholesale, OEM/ODM ready.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 0Cr27Al7Mo2 Wire Kanthal APM Alternative

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support