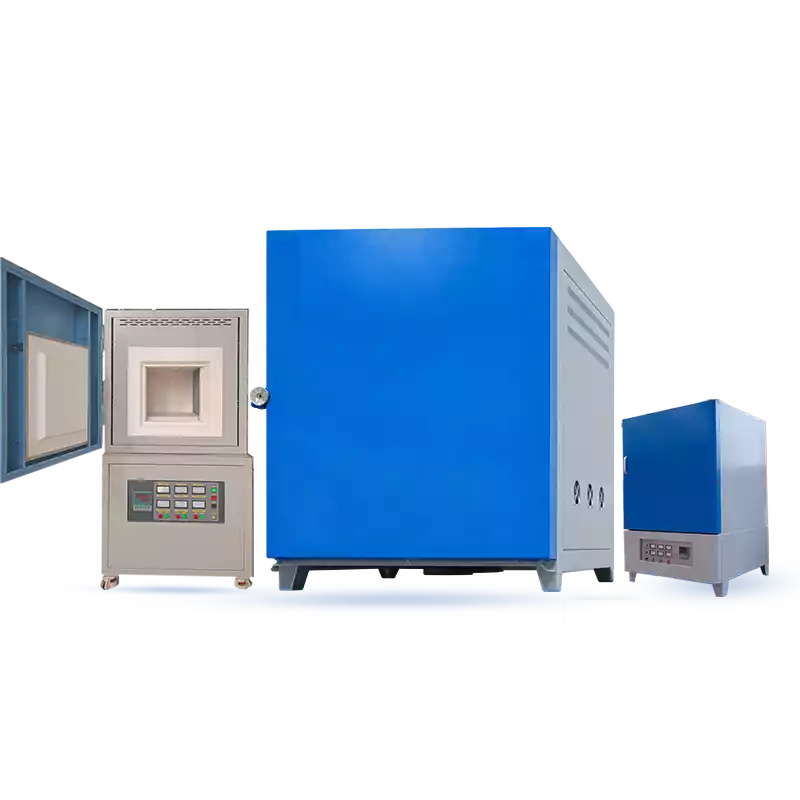

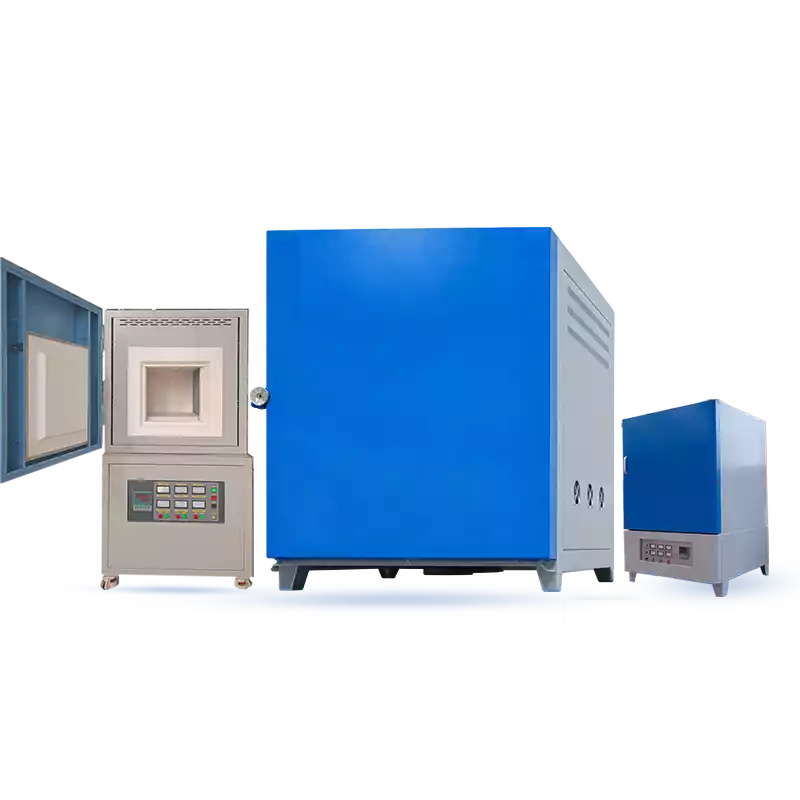

The 1200°C large muffle furnace is designed for factories and large experiments, offering chamber sizes from 216L to 1000L to accommodate multiple samples simultaneously, heat-treat ceramics and metals, and develop heating processes.

This furnace is equipped with HRE FeCrAl resistance wire and energy-efficient ceramic fiber insulation, providing rapid heating and sustained stable operation while effectively minimizing energy consumption. The precision PID control system ensures uniform temperatures throughout the chamber, making it well-suited to stringent heat treatment requirements. Orders are accepted from a single unit, offering international shipping and flexible customization of dimensions and functions to meet specific needs.

CVSIC 1200°C Large Muffle Furnace Features

- High-Temperature Performance: Maximum temperature of 1200°C, with stable operation at 1100°C, accommodating diverse high-temperature processing requirements.

- Large-Capacity Chamber: 216L to 1000L volumes, optimized for medium-to-large experiments and industrial production, balancing efficiency and scale.

- Energy-Efficient Design: Low-conductivity mullite fiber chamber cuts energy use.

- Premium Heating Elements: HRE FeCrAl wire ensures even heating and long life.

- Intelligent Control: 50-segment program automates complex processes for efficiency.

- Safety Features: Overtemperature alarm and double-layer air cooling keep the shell under 60°C.

- User-Friendly Operation: Custom top or side doors keep operators safely distant from heat.

- Durable Construction: Reinforced roof prevents sagging and boosts reliability.

CVSIC 1200°C Large Muffle Furnace Applications

- Universities and Research Institutes: Perfect for medium-to-large experiments in materials science, chemistry, and physics, including large-scale sintering, heat treatment, and material performance testing.

- Medium-to-Large Enterprises: Supports high-volume production lines for sintering, melting, tempering, and ashing in ceramics, metallurgy, chemicals, and similar industries.

- Special Requests: Custom features and sizes for unique jobs or needs.

CVSIC 1200°C Large Muffle Furnace Application Scenarios

- Batch Heat Treatment of Metal Parts and Tools: Annealing and tempering of alloy steels, tool steels, and carbon steels.

Enables continuous operation with multi-layer tray configurations.

- Sintering of Ceramic Products and Refractory Materials: Large-scale production of industrial ceramics, honeycomb ceramics, and structural ceramics.

Keeps even heat for long jobs at high temperatures.

- Thermal Processing of Glass and Mineral Products: Tempering, annealing, and fining treatments.

Big chamber fits large sheets or molds easily.

- Sintering or Degassing of Electrical and Electronic Components: Heat treatment for resistors, insulators, ceramic packages, and more.

Works with systems that control the heating atmosphere.

- High-Temperature Process Integration for Industrial Lines: Seamlessly integrates into automated production lines with conveyor systems.

Can work with remote controls and track temperature changes.

1200°C Large Muffle Furnace Customization

CVSIC offers comprehensive customization options, including:

- Chamber Sizes: Specify your required chamber volume from 216L up to 1000L or request larger sizes for unique applications.

- Door Configurations: Choose from top-opening or side-opening door designs to suit your workflow and facility layout.

- Control Systems: Select enhanced controls, including multi-segment programming and workflow integration to match process automation needs.

- Additional Features: Request specific adaptations such as alternative heating elements, atmosphere control systems, or special process parameters as needed for your application.

We accept orders starting from one unit, offer prompt worldwide shipping, and provide expert technical support and after-sales service to ensure smooth integration into your operations.

Why Choose the CVSIC 1200°C Large Muffle Furnace?

- Trusted Brand: CVSIC delivers integrated heating solutions for global high-temperature industries.

- High-Capacity Efficiency: 216-1000L volumes meet medium-to-large experimental and production demands.

- Energy-Saving: Uses better insulation and heater parts to lower power use.

- Flexible Customization: Options from sizes to functions tailored to your requirements.

- Global Support: Single-unit orders with prompt worldwide delivery.

- Safe and Reliable: Many safety systems protect people and equipment.

Contact CVSIC for a customized 1200°C large muffle furnace solution designed to meet your needs—advance your research and production with confidence.