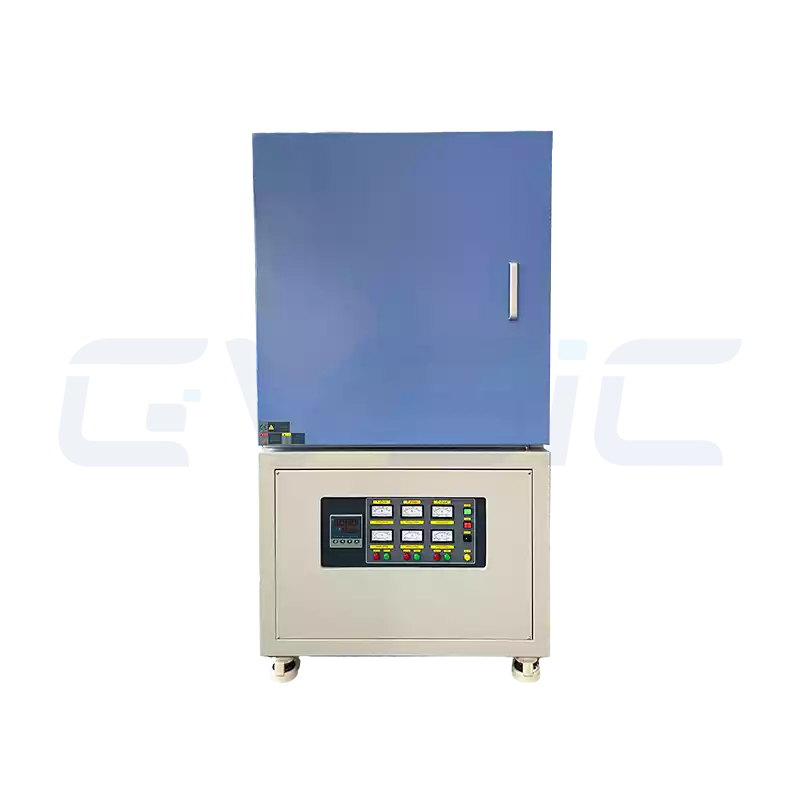

1400°C Large Muffle Furnace

1400°C Large Industrial Muffle Furnace

The CVSIC 1400°C large muffle furnace offers capacities ranging from 216L to 1000L, a maximum temperature of 1400°C, precise control, and durable, energy-efficient operation. Ideal for large-scale sintering, heat treatment, and ashing. Worldwide shipping available, starting from one unit!

- Name: CVSIC 1400°C Large Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

Unlock seamless high-volume processing with the CVSIC 1400°C large muffle furnace, purpose-built for medium-to-large mining, industrial enterprises, universities, and research institutes. Choose from 216L to 1000L chambers—engineered to empower your teams for efficient, scalable heat treatment of ceramic products, metal components, and powder metallurgy samples.

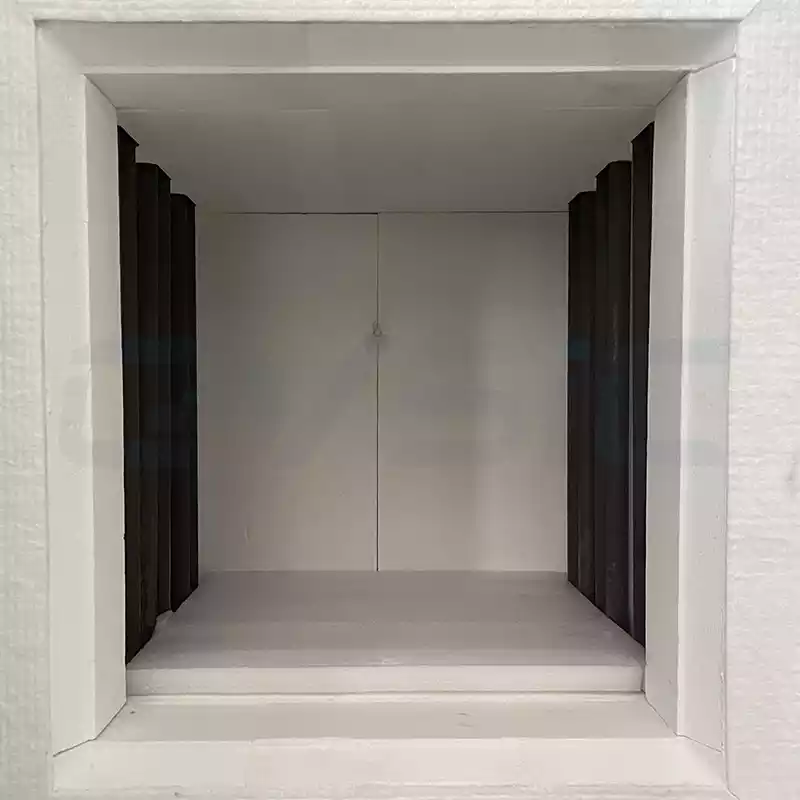

Leverage leading-edge technology with a polycrystalline mullite fiber chamber and U-shaped silicon carbide heating elements—delivering reliability and energy efficiency at 1400°C. With generous 216–1000L capacities and an optimized design, maximize productivity in large-scale production and advanced research. Dominate sintering, melting, tempering, ashing, or heat treatment workflows for metals, non-metals, and compound materials.

CVSIC 1400°C Large Muffle Furnace Features

- Large-Capacity Design: 216-1000L chambers meet demands for large-scale industrial and research applications.

- High-Temperature Precision: Type S thermocouple with 50-segment programmable control for stable operation at 1400°C.

- Energy-Efficient and Durable: Polycrystalline mullite fiber chamber and reinforced roof reduce energy bills and maintenance needs, ensuring years of reliable use for your processes.

- Premium Heating Elements: Silicon carbide elements ensure uniform heating, high-temperature resistance, and suitability for complex material processing.

- Safe and Reliable: Overtemperature alarm, double-layer air-cooling (shell <60°C), and optional door configurations.

- User-Friendly Operation: Customizable top- or side-opening doors keep operators away from heat sources for enhanced comfort.

- Durable Construction: Reinforced composite roof prevents sagging over prolonged use, ensuring consistent performance.

- Flexible Customization: Choose from multiple sizes, doors, and controls to ensure the furnace is a perfect fit for your specific workflow and requirements.

Suitable Environments and Users

Operating Environments

- Large Industrial Production Lines: Such as ceramics manufacturing plants, metallurgy factories, or chemical material workshops, where 216-1000L capacities enable high-volume material processing to meet production quotas.

- Integrated Research Centers: Like national materials research institutions or corporate R&D hubs, handling large samples or multi-batch experiments in high-throughput testing setups.

- High-Temperature Batch Production Settings: Industrial scenarios requiring sustained stable operation, with efficient cooling and robust design for uninterrupted manufacturing.

- Multi-Material Processing Environments: Production lines managing diverse materials or oversized samples, where 216-1000L volumes offer adaptability to intricate processes.

Target Users

- Industrial Manufacturers: Producers of ceramics, alloys, or composites needing bulk sintering or heat treatment to fulfill market demands, focusing on output and cost efficiency.

- Advanced Research Teams: Engaged in large-scale material development, such as aerospace materials, renewable energy components, or high-performance ceramics, requiring high-capacity equipment for high-throughput experiments.

- Production Managers: Overseeing large production lines and selecting high-performance, energy-efficient, and durable high-temperature solutions.

- Corporate R&D Departments: In automotive, energy, or chemical sectors, processing large samples or multi-batch tests while bridging research and production validation.

Recommended Scenarios

- Large-scale sintering of ceramic products, such as industrial ceramic components, tiles, or functional ceramics.

- Bulk heat treatment of metal parts in automotive, aerospace, or mechanical manufacturing for material optimization.

- Thermal decomposition or ashing analysis of large samples in chemical, environmental, or materials science fields.

- High-throughput material performance testing, like for renewable energy battery materials or high-temperature alloys.

Customization and Services

CVSIC offers versatile customization services, including:

- Chamber Sizes: Tailored from 216-1000L or larger to suit your production or experimental needs.

- Door Configurations: Options for top- or side-opening to optimize handling.

- Control Systems: Enhanced programmable controls adapted to specialized process workflows.

- Additional Features: Adjustments to heating elements or parameters based on applications.

Benefit from our commitment to your success: order as little as one unit and enjoy rapid global shipping. Rely on expert technical consulting and after-sales support to guarantee your new furnace integrates smoothly into your production or research workflows—driving immediate value and results.

Why Choose CVSIC 1400°C Large Muffle Furnace?

- Brand Reliability: CVSIC specializes in one-stop solutions for global high-temperature industries.

- High-Capacity Efficiency: 216-1000L volumes support large-scale production and high-throughput experiments.

- High-Temperature Capability: 1400°C with precise control, ideal for demanding processes.

- Energy-Saving and Durable: Optimized insulation and heating design reduces consumption and extends lifespan.

- Flexible Customization: Comprehensive tailoring of sizes and functions for personalized requirements.

- Global Service: Single-unit orders with swift worldwide delivery.

- Safe and Robust: Multi-layered safety features protect personnel and equipment.

Contact CVSIC now to secure your customized 1400°C large muffle furnace and position your research and production for peak performance and industry leadership!

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1400°C Large Muffle Furnace

1400°C Medium Muffle Furnace

- Name: CVSIC 1400°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Small Muffle Furnace

- Name: CVSIC 1400°C Small Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support