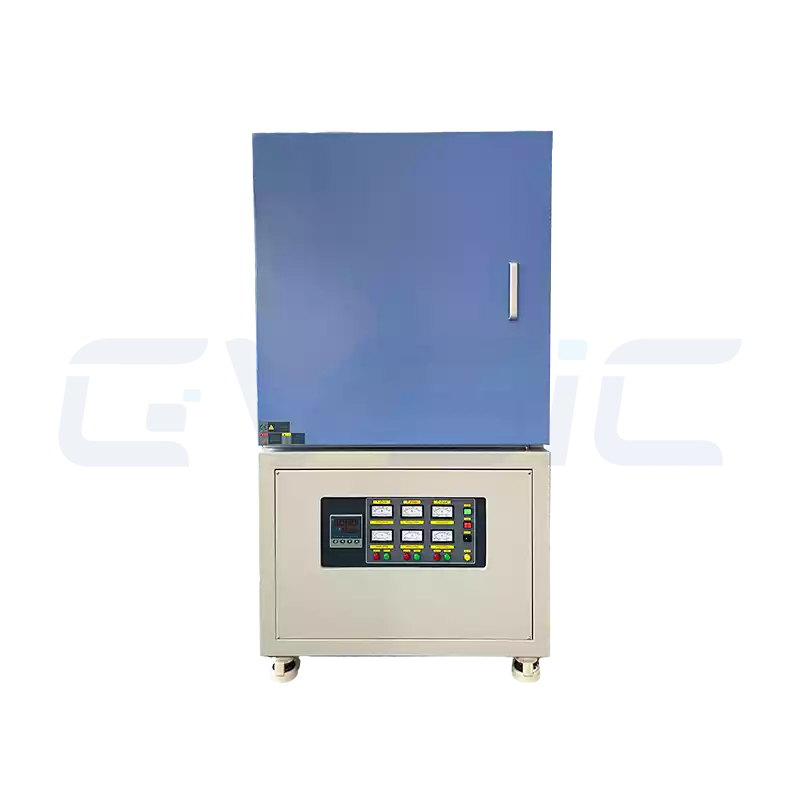

1400°C Small Muffle Furnace

1400°C Mini Laboratory Muffle Furnace

The CVSIC 1400°C small muffle furnace features capacities of 1-12L, a maximum temperature of 1400°C, and an operating temperature of 1300°C, with precise control and durable, energy-efficient performance. Ideal for lab sintering, heat treatment, and ashing. Global shipping, starting from one unit!

- Name: CVSIC 1400°C Small Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

The 1400°C small muffle furnace is designed for research labs, academic teaching, and small-sample heat treatment, offering a small footprint, reliable high-temperature stability, and excellent control precision. You can select chamber volumes from 1L to 12L, or request custom dimensions, making it a top choice for powder materials, ceramic samples, metal sheets, and small-batch heat treatment in R&D.

This compact muffle furnace reaches 1400°C and features a fiber chamber with SiC heating elements for efficient, balanced performance. Ideal for small labs and production, it supports sintering, melting, tempering, ashing, and heat treatment.

CVSIC 1400°C Small Muffle Furnace Features

- High-Temperature Performance: Maximum temperature of 1400°C, with sustained operation at 1300°C, meeting stringent sintering and heat treatment requirements.

- Compact Capacity Design: 1-12L chambers fit small experiments and save space.

- Energy-Efficient Operation: Polycrystalline mullite fibre chamber with low thermal conductivity for superior insulation and reduced energy use.

- Premium Heating Elements: SiC Heating elements deliver even, high-temp heating for complex processes.

- Intelligent Control: 50-segment program automates and speeds experiments.

- Safety Features: Overheat alarm and air-cooling keep the outer shell cool.

- User-Friendly Operation: Top or side-opening doors keep operators away from heat sources.

- Durable Construction: Reinforced roof prevents sagging and supports long-term use.

Note: Custom dimensions available to meet specific experimental needs.

CVSIC 1400°C Small Muffle Furnace Suitable Environments and Users

Operating Environments

- Compact Labs: Perfect for space-limited university or research institute labs in materials science, chemistry, or physics. The 1-12L compact design fits easily on workbenches, supporting high-precision experiments.

- High-Demand Experimental Settings: Scenarios requiring 1400°C temperatures, such as high-performance ceramic sintering, metal alloy heat treatment, or compound decomposition analysis, especially for small-batch samples.

- Teaching Labs: In universities or technical training centres for materials heat treatment demonstrations, with simple operation ideal for student use.

- Small Production Workshops: Such as mini ceramic workshops or precision parts factories, balancing cost and efficiency for small-batch high-temperature processing.

Target Users

- Materials Scientists: Involved in high-performance material R&D, including sintering and performance testing of advanced ceramics, composites, or high-temperature alloys.

- Chemistry Researchers: Conducting small-scale compound decomposition, ashing, or thermal analysis experiments requiring precise temperature control.

- Small Business Owners: In jewellery processing, ceramic crafting, or small metal parts manufacturing, prioritising compact design, low energy use, and high efficiency.

- Educators: University or vocational trainers needing safe, user-friendly equipment for student experiments and training.

- Startup R&D Teams: With limited budgets but requiring high-performance high-temperature tools, where 1-12L capacity and 1-7kW low power reduce operating costs.

Recommended Scenarios

- Sintering small quantities of high-performance ceramic samples, such as oxide or functional ceramics.

- Small-scale metal alloy heat treatment to enhance strength and toughness.

- Ashing analysis for organic content detection or environmental sample testing.

- Thermal decomposition experiments in compact labs to study material high-temperature behaviour.

CVSIC 1400°C Small Muffle Furnace Customization

CVSIC offers flexible customization services, including:

- Chamber Sizes: Tailored from 1-12L or larger to align with your experimental requirements.

- Door Configurations: Options for top- or side-opening to improve handling.

- Control Systems: Enhanced programmable controls adapted to specialized experimental protocols.

- Additional Features: Modifications to heating elements or parameters based on applications.

We guarantee orders as small as a single unit, rapid global shipping, and comprehensive technical consulting with proactive after-sales support, ensuring unique convenience and seamless integration into experimental workflows.

Why Choose the CVSIC 1400°C Compact Muffle Furnace?

- Brand Reliability: CVSIC specializes in one-stop solutions for global high-temperature industries.

- Compact and Efficient: 1-12L capacities fit small labs and production seamlessly.

- High-Temperature Capability: 1400°C performance meets demanding experimental needs.

- Energy-Saving and Durable: Optimized insulation and heating extend lifespan while cutting energy use.

- Flexible Customization: Full tailoring of sizes and functions for personalized demands.

- Global Service: Single-unit orders with swift worldwide delivery.

Contact CVSIC right now to customise your 1400°C samll muffle furnace and elevate your research and production to new heights!

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1400°C Small Muffle Furnace

1400°C Large Muffle Furnace

- Name: CVSIC 1400°C Large Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Medium Muffle Furnace

- Name: CVSIC 1400°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support