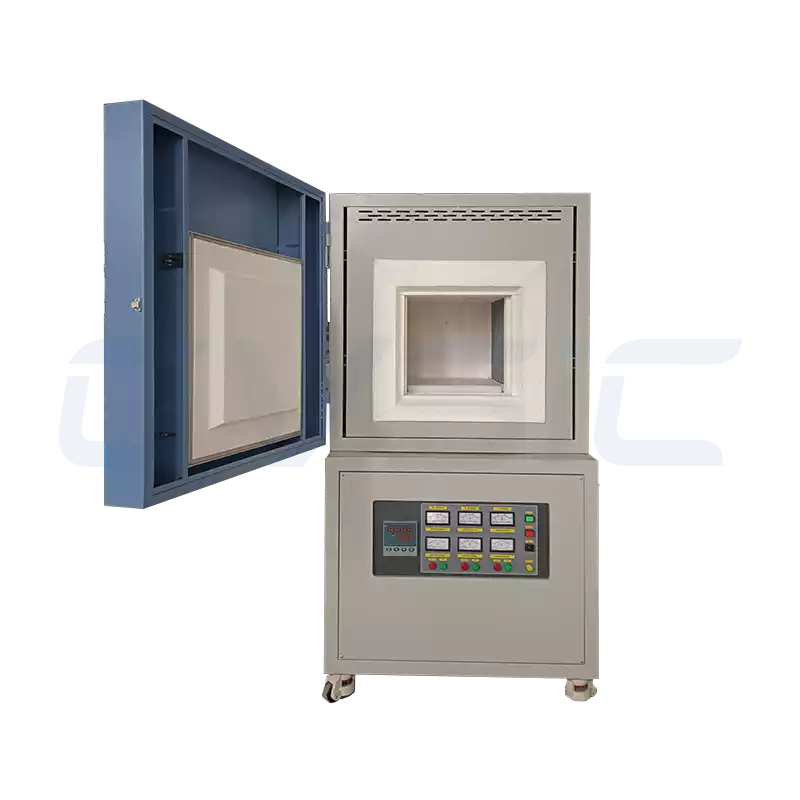

1700°C Large Muffle Furnace

1700°C High-Temperature Industrial Muffle Furnace

The CVSIC 1700°C large muffle furnace offers a capacity of 216-1000L, achieving up to 1700°C with precise temperature control and an energy-efficient, durable build. Perfect for large-scale sintering, heat treatment, and ashing applications. Worldwide shipping available, starting from just one unit!

- Name: CVSIC 1700°C Large Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

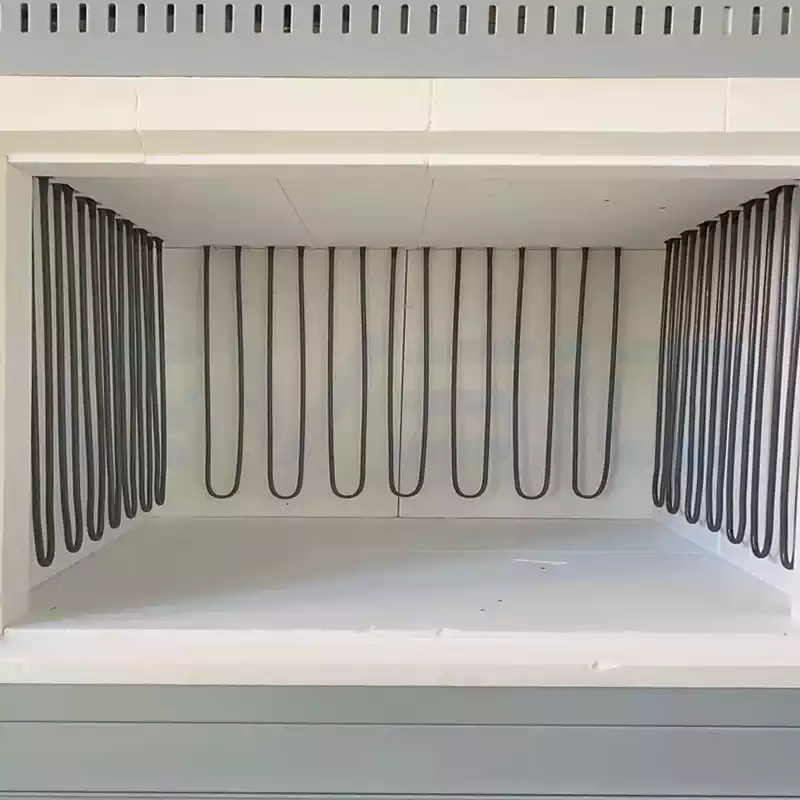

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C large muffle furnace is designed to make high-volume industrial material processing efficient and dependable. Users benefit from MoSi2 heating elements that ensure consistent peak performance at 1700°C, providing stable operation that enhances workflow reliability and product quality even in demanding production settings.

FWith a chamber size of 216L to 1000L, this large furnace can handle bulk ceramics, metal treatment, and making new materials in big amounts.

The polycrystalline mullite fiber chamber delivers excellent energy savings for users, minimizing operational costs while maintaining stable high-temperature conditions. The B-type thermocouple and programmable temperature control ensure operators achieve precise, uniform heating of large volumes, reducing the risk of quality issues.

CVSIC 1700°C Large Muffle Furnace Features

- Ultra-High-Temperature Capability: Maximum 1700°C with 1600°C operating temperature, ideal for demanding ultra-high-temperature sintering and heat treatment.

- Large-Capacity Chamber: Offers 216-1000L for industrial-scale production and testing, maximizing throughput and batch size efficiency.

- High-Efficiency Energy Savings: Polycrystalline mullite fiber chamber delivers superior insulation, cutting energy costs and minimizing heat loss.

- Premium Heating Elements: Molybdenum disilicide elements ensure even, rapid heating and withstand repeated use at 1700°C for consistent operations.

- Advanced Control: 50-segment programmable automation enables precise, repeatable thermal processes and reduces manual intervention.

- Robust Safety Features: Over-temperature alarms and dual-layer air cooling (shell <60°C) proactively protect users and equipment.

- User-Friendly Operation: Customizable top- or side-opening doors keep users protected from heat and allow flexible operation to suit workflow.

- Durable Construction: Reinforced composite roof prevents sagging during long-term high-temp use, ensuring sustained reliability.

CVSIC 1700°C Large Muffle Furnace Applications and Users

Application Environments

- Large industrial production lines with a capacity of 216-1000L support ultra-high-temperature processes in ceramics, metallurgy, and chemical manufacturing, meeting demanding production needs.

- Comprehensive research centers: Enable high-throughput, ultra-high-temperature testing of large or multiple samples for institutes and major R&D teams.

- Ultra-high-temperature batch production: Ideal for settings needing stable, continuous, and durable operation.

- Multi-material environments: Handle diverse or oversized samples; 216-1000L chamber allows flexible, complex workflows.

Target Users

- Industrial Manufacturers: Producers of high-performance ceramics, specialty alloys, or composites needing bulk ultra-high-temperature sintering or heat treatment to fulfill market demands, with emphasis on output and cost management.

- Advanced Research Teams: Involved in large-scale ultra-high-temperature material development, such as aerospace materials, renewable energy components, or advanced ceramics, requiring high-capacity equipment for high-throughput testing.

- Production Managers: Overseeing large-scale lines and selecting equipment that delivers high performance, energy efficiency, and durability in ultra-high-temperature applications.

- Corporate R&D Departments: In automotive, energy, or chemical sectors, processing large samples or multi-batch experiments while bridging research and production validation.

Recommended Scenarios

- Large-Scale Sintering of High-Performance Ceramics, such as zirconia, silicon nitride, or functional ceramic components.

- Bulk Heat Treatment of Specialty Alloys for aerospace, automotive, or mechanical manufacturing material optimization.

- Ultra-High-Temperature Thermal Decomposition or Ashing Analysis of Large Samples, applicable in chemical, environmental, or materials science fields.

- High-Throughput Material Performance Testing, like renewable energy battery materials or high-temperature alloy development.

CVSIC 1700°C Large Muffle Furnace Customization and Services

CVSIC provides flexible customization options, including:

- Chamber Dimensions: 216-1000L or larger capacities tailored to specific production or experimental needs.

- Door Configurations: Top- or side-opening options to optimize user experience.

- Control Systems: Enhanced programmable features customized for specialized process workflows.

- Additional Features: Adjustments to heating elements or control parameters based on application requirements.

Orders start from one unit and include fast global shipping, technical consultation, and after-sales support, making it easy for users to integrate the furnace into production or experimentation without logistical concerns.

Why Choose the CVSIC 1700°C Large Muffle Furnace?

- Trusted Brand: CVSIC specializes in comprehensive one-stop solutions for global high-temperature industrial applications.

- Superior Ultra-High-Temperature Performance: 1700°C capability to meet the most rigorous process demands.

- High-Capacity Efficiency: 216-1000L volume, optimized for large-scale production and high-throughput experiments.

- Energy-Saving Durability: Advanced insulation and heating design minimizes consumption while extending lifespan.

- Versatile Customization: Full adaptability in size and features to address unique requirements.

- Global Support: Single-unit orders with swift delivery worldwide.

- Dependable Safety: Multi-layered safeguards protect operators and equipment.

Contact CVSIC to discuss how customizing your 1700°C large muffle furnace can help optimize your specific research or production processes, ensuring you get the best fit for your requirements.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1700°C Large Muffle Furnace

1800°C Industrial Muffle Furnace

- Name: CVSIC 1800°C Industrial Muffle Furnace

- Temperature: Maximum of 1800°C and operating temperature of 1700°C

- Heater: MoSi2 Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

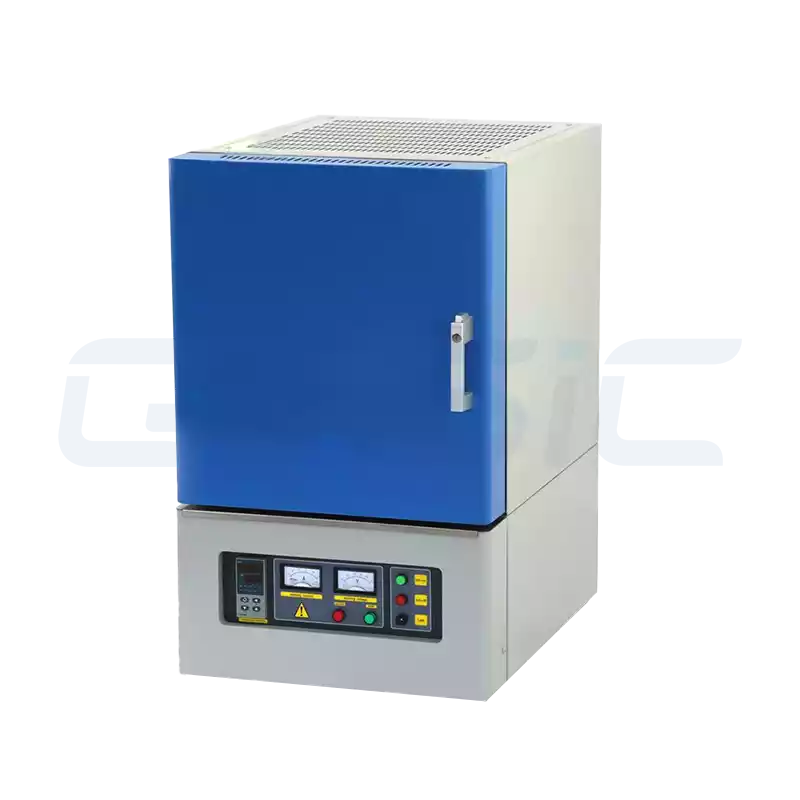

1800°C Small Muffle Furnace

- Name: CVSIC 1800°C Small Muffle Furnace

- Temperature: Maximum temperature of 1800°C, with stable operation at 1700°C

- Heater: U-shaped MoSi2 heating element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Medium Muffle Furnace

- Name: CVSIC 1700°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Small Muffle Furnace

- Name: CVSIC 1700°C Small Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support