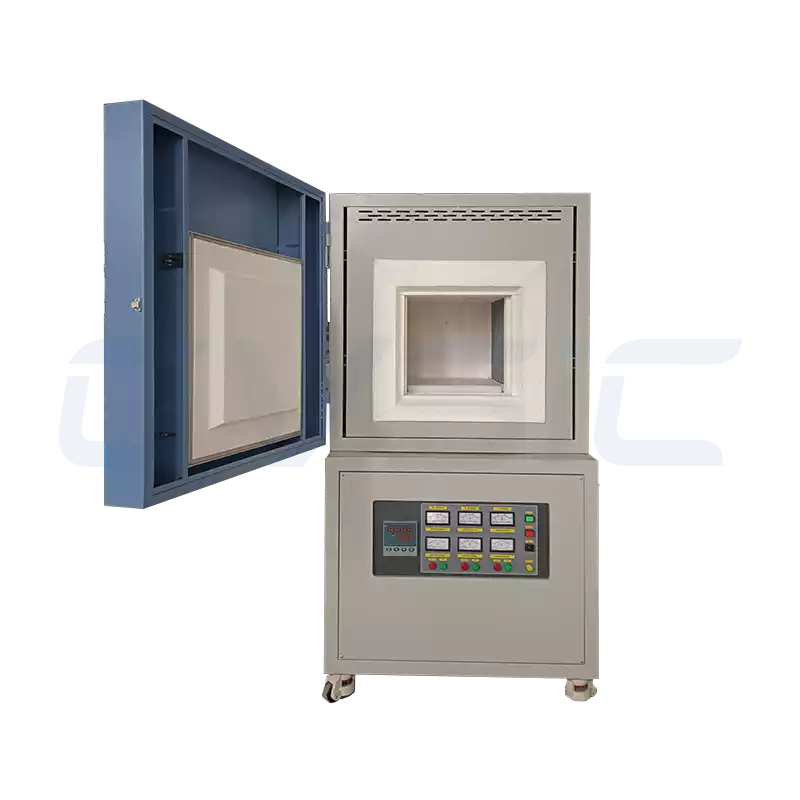

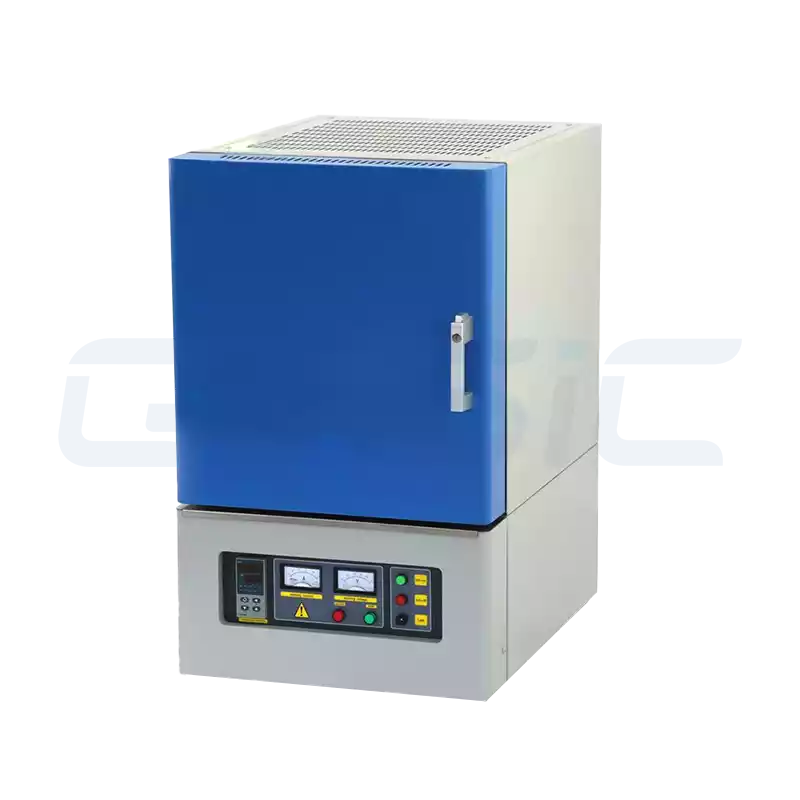

1700°C Medium Muffle Furnace

1700°C Electric Heating Muffle Furnace

The CVSIC 1700°C medium muffle furnace offers a capacity of 27-125L, reaching up to 1700°C with a stable operating temperature of 1600°C. It features precise temperature control and an energy-efficient, durable design. Ideal for ultra-high-temperature sintering, heat treatment, and ashing processes. Worldwide shipping available, with orders starting from just one unit!

- Name: CVSIC 1700°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C medium muffle furnace uses MoSi2 heating elements to reach 1700°C and maintain 1600°C stable operation. Offering a 27–125L chamber, it supports scaling research to pilot production, small-batch manufacturing, and industrial use.

This box-type muffle furnace incorporates high-purity alumina fiber composite insulation to enhance energy efficiency and operational longevity. It offers rapid heating, uniform temperature distribution, and precise control. The B-type thermocouple and programmable control system accommodate complex heat treatment requirements.

CVSIC 1700°C Medium Muffle Furnace Features

- Medium Capacity: 27–125L chamber designed for medium-scale applications.

- Ultra-High-Temperature Precision: B-type thermocouple and 50-segment control for stable 1600°C performance.

- Energy-Efficient and Durable: Polycrystalline mullite fiber chamber reduces energy use and boosts lifespan.

- High-Quality Heating Elements: Molybdenum Disilicide Heating elements for uniform, ultra-high-temperature heating.

- Intelligent Control: 50-segment automation streamlines workflows and improves efficiency.

- Safe and Reliable: Over-temperature alarms, air cooling, and safety door options.

- Flexible Customization: Adjustable size, doors, and controls for your needs.

CVSIC 1700°C Medium Muffle Furnace Applications and Users

Application Environments

- Medium-Scale Advanced Labs: Perfect for university materials engineering, chemistry, or physics labs, where the 27-125L capacity supports medium-scale experiments, such as pilot development of high-performance ceramics or specialty alloys.

- Small- to Medium-Sized Industrial Workshops: Suited for ceramics factories, specialty materials processing plants, or chemical materials production facilities, enabling medium-batch ultra-high-temperature treatments while balancing productivity and equipment versatility.

- Versatile Production Settings: Ideal for environments handling diverse materials or medium-batch samples, with 27-125L capacity adapting flexibly to varying sizes and process requirements.

- R&D-to-Production Hybrid Environments: Such as corporate R&D centers or pilot lines, where it supports both experimental validation and small-batch production in semi-industrial ultra-high-temperature applications.

Target Users

- Materials Engineers: For ultra-high-temperature R&D, including sintering and heat treatment of oxide ceramics, nitride ceramics, specialty alloys, or composites.

- Small- and Medium-Sized Manufacturers: Producers of high-performance ceramics, specialty alloys, or chemical materials requiring medium-batch production of premium-quality items, with a focus on equipment durability and energy efficiency.

- Research Institutions: Government- or corporate-funded materials R&D centers needing medium-sized units for multi-batch ultra-high-temperature experiments or pilot production.

- Technical Managers: Those responsible for lab or production line equipment selection, seeking solutions that balance ultra-high-temperature performance, cost-effectiveness, and adaptability.

Recommended Scenarios

- Medium-Batch Sintering of High-Performance Ceramics, such as zirconia, silicon nitride, or functional ceramics production.

- Medium-Scale Heat Treatment of Specialty Alloys to enhance high-temperature properties, as in aerospace or renewable energy materials.

- Performance Testing and Optimization of Composites, ideal for demanding research projects.

- Pilot-Stage Thermal Decomposition or Ashing Analysis of Chemical Materials, addressing both R&D and production needs.

CVSIC 1700°C Medium Muffle Furnace Customization and Services

CVSIC offers flexible customization services, including:

- Chamber Dimensions: 27-125L or larger capacities tailored to precise experimental or production needs.

- Door Configurations: Options for top-opening or side-opening doors to enhance user experience.

- Control Systems: Advanced programmable features customized for specialized process workflows.

- Additional Features: Adjustments to heating elements or control parameters based on application requirements.

We offer single-unit orders, prompt global shipping, and comprehensive technical and after-sales support to assist with integration into laboratory or production environments.

Why Choose the CVSIC 1700°C Medium Muffle Furnace?

- Proven Brand: CVSIC delivers comprehensive one-stop solutions for global high-temperature industrial needs.

- Exceptional Ultra-High-Temperature Performance: 1700°C capability to handle the most demanding experiments and production tasks.

- Efficient Medium-Scale Design: 27-125L capacity perfectly suited for medium-scale labs and manufacturing.

- Energy-Saving Durability: Optimized insulation and heating for reduced consumption and prolonged reliability.

- Comprehensive Customization: Full flexibility in size and features to align with unique requirements.

- Worldwide Support: Single-unit orders with rapid delivery across the globe.

- Robust Safety: Multiple safeguards to protect operators and equipment.

Contact CVSIC to customize your 1700°C medium muffle furnace. Elevate your research and production now.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1700°C Medium Muffle Furnace

1800°C Industrial Muffle Furnace

- Name: CVSIC 1800°C Industrial Muffle Furnace

- Temperature: Maximum of 1800°C and operating temperature of 1700°C

- Heater: MoSi2 Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1800°C Small Muffle Furnace

- Name: CVSIC 1800°C Small Muffle Furnace

- Temperature: Maximum temperature of 1800°C, with stable operation at 1700°C

- Heater: U-shaped MoSi2 heating element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Large Muffle Furnace

- Name: CVSIC 1700°C Large Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Small Muffle Furnace

- Name: CVSIC 1700°C Small Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support