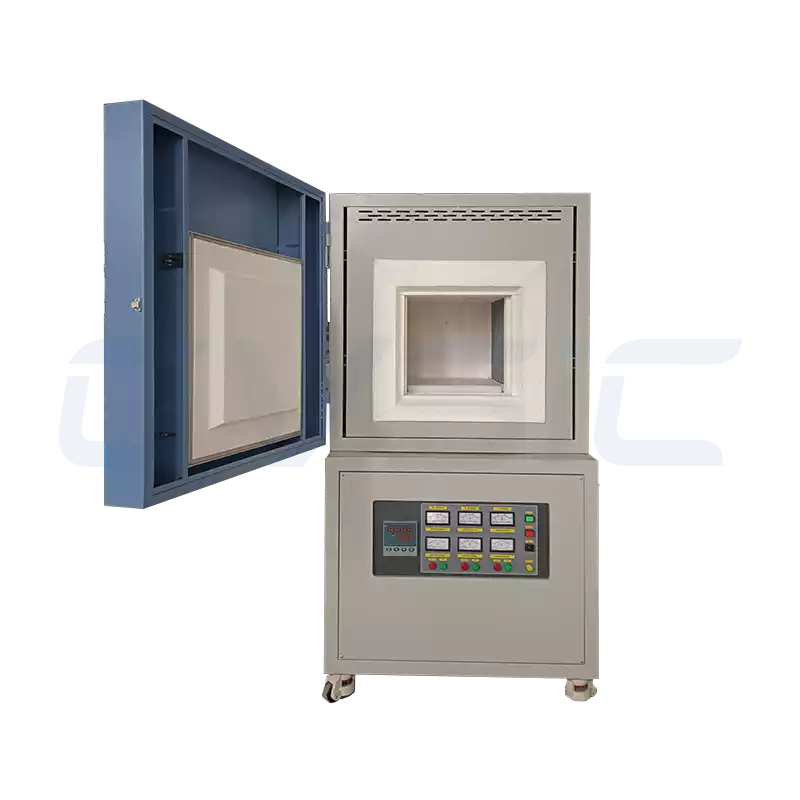

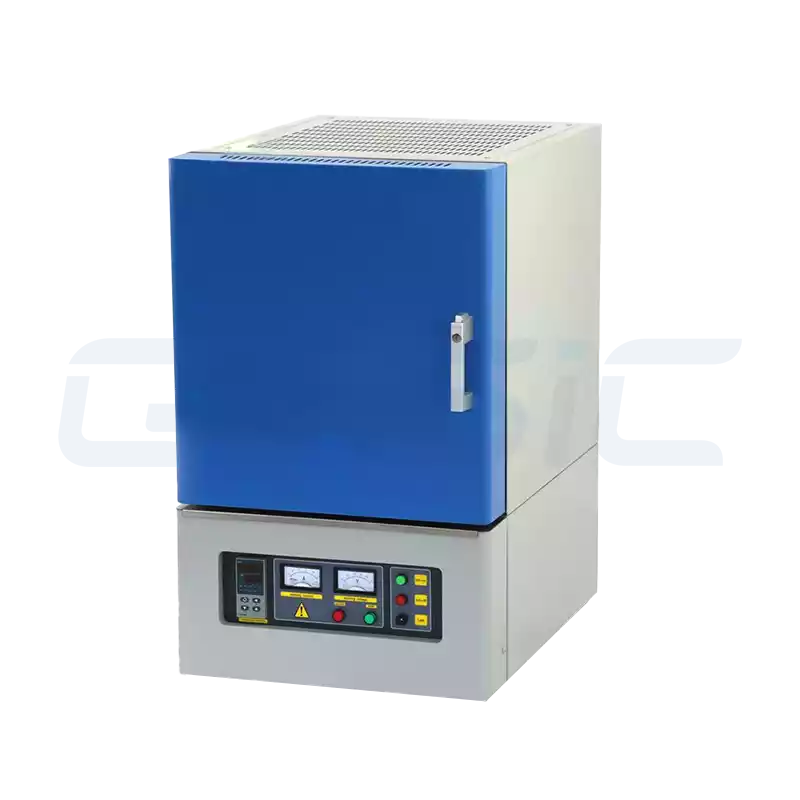

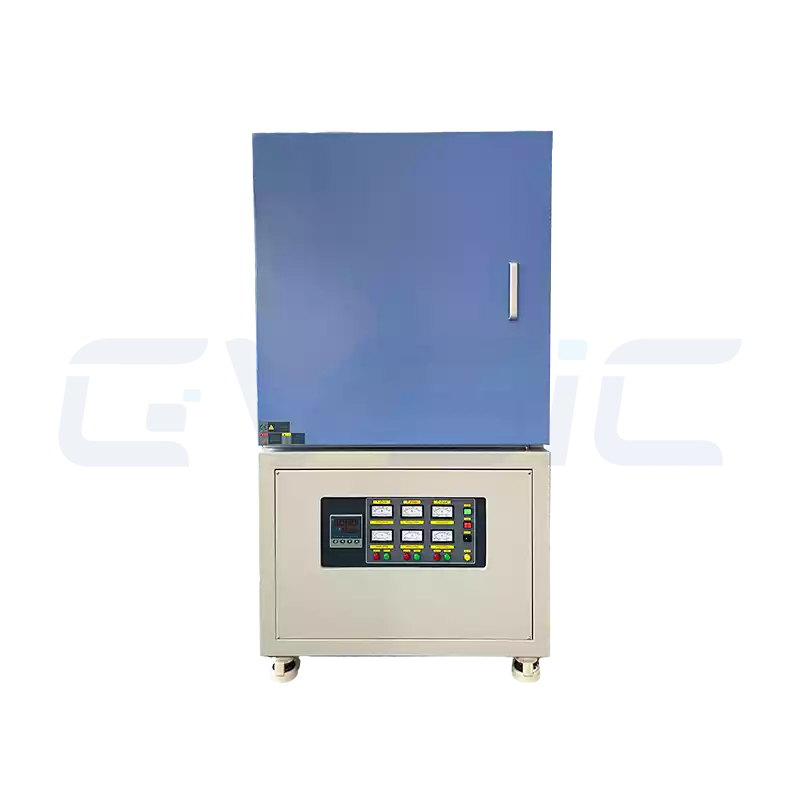

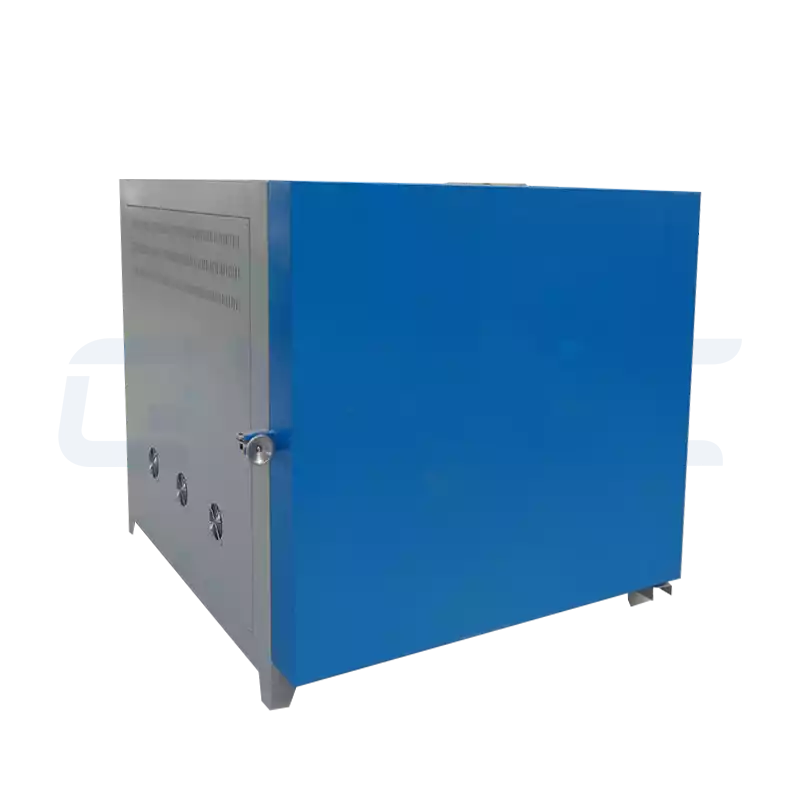

1800°C Industrial Muffle Furnace

1800°C High-Temperature Industrial Muffle Furnace

- Name: CVSIC 1800°C Industrial Muffle Furnace

- Temperature: Maximum of 1800°C and operating temperature of 1700°C

- Heater: MoSi2 Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

CVSIC 1800°C Industrial muffle furnace serves universities, research institutes, and medium-scale mining and industrial enterprises. It reaches 1800°C maximum temperature and uses high-quality polycrystalline mullite fiber insulation with CVSIC molybdenum disilicide heating elements for sustained 1700°C operation and 1800°C peak temperatures.

Chamber volumes of 27-36L make this furnace ideal for mid-scale labs and semi-industrial production. Use it for ultra-high-temperature sintering, melting, tempering, ashing, and heat treatment of metals, non-metals, and compounds.

Order a single unit, get rapid global shipping, and customize dimensions and functions to match your mid-scale experimental and production needs.

1800°C Industrial Muffle Furnace Features

- Ultra-High-Temperature Performance: Maximum of 1800°C and operating temperature of 1700°C, meeting demanding ultra-high-temperature sintering and heat treatment needs.

- Medium Capacity: 27-36L volumes suit mid-scale use, balancing efficiency.

- Energy-Efficient Design: Mullite fiber chamber insulates, cutting energy use.

- Premium Heating Elements: MoSi2 rods deliver uniform, high-temperature heating.

- Intelligent Control: 50-segment automation boosts process efficiency.

- Safety Features: Overtemperature alarm and double-layer cooling keep the shell cool.

- User-Friendly Operation: Customizable doors keep operators safe from heat.

- Durable Construction: Reinforced roof ensures consistent long-term use.

Suitable Environments and Users

Operating Environments

Target Users

- Materials Engineers: Focused on pilot-stage ultra-high-temperature material development, such as sintering and heat treatment of oxide ceramics, nitride ceramics, ultra-high-temperature alloys, or advanced composites.

- Small-to-Medium Manufacturers: Producers of high-performance ceramics, specialty alloys, or chemical materials requiring mid-batch quality output, emphasizing equipment durability and efficiency.

- Research Institutions: Government- or corporate-funded materials R&D centers needing mid-sized units for multi-batch ultra-high-temperature experiments or pilot production.

- Technical Managers: Responsible for lab or line equipment selection, seeking solutions that balance ultra-high-temperature capability, cost, and flexibility.

Recommended Scenarios

- Mid-batch advanced ceramic sintering, such as zirconia, silicon carbide, or silicon nitride production.

- Mid-scale ultra-high-temperature alloy heat treatment to optimize properties, like in aerospace or renewable energy materials.

- Performance testing and optimization of composites for high-stakes research projects.

- Pilot-stage chemical material thermal decomposition or ashing analysis, bridging research and production.

Customization and Services

CVSIC provides versatile customization services, including:

- Chamber Sizes: Tailored from 27-36L or larger to fit your experimental or production needs.

- Door Configurations: Options for top- or side-opening to enhance usability.

- Control Systems: Advanced programmable features adapted to specialized process workflows.

- Additional Features: Adjustments to heating elements or parameters based on applications.

Order one unit, get global delivery, and access technical consulting and after-sales support for easy integration into your lab or production.

Contact CVSIC to customize your 1800°C furnace and raise your research and production performance.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1800°C Industrial Muffle Furnace

1800°C Small Muffle Furnace

- Name: CVSIC 1800°C Small Muffle Furnace

- Temperature: Maximum temperature of 1800°C, with stable operation at 1700°C

- Heater: U-shaped MoSi2 heating element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Large Muffle Furnace

- Name: CVSIC 1700°C Large Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Medium Muffle Furnace

- Name: CVSIC 1700°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Small Muffle Furnace

- Name: CVSIC 1700°C Small Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Large Muffle Furnace

- Name: CVSIC 1400°C Large Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Medium Muffle Furnace

- Name: CVSIC 1400°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Elements

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1400°C Small Muffle Furnace

- Name: CVSIC 1400°C Small Muffle Furnace

- Temperature: Maximum temperature of 1400°C, with stable operation at 1300°C

- Heater: SiC Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1200°C Large Muffle Furnace

- Name: CVSIC 1200°C Large Muffle Furnace

- Temperature: Maximum temperature of 1200°C, with stable operation at 1100°C

- Heater: HRE FeCrAl resistance wire

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support