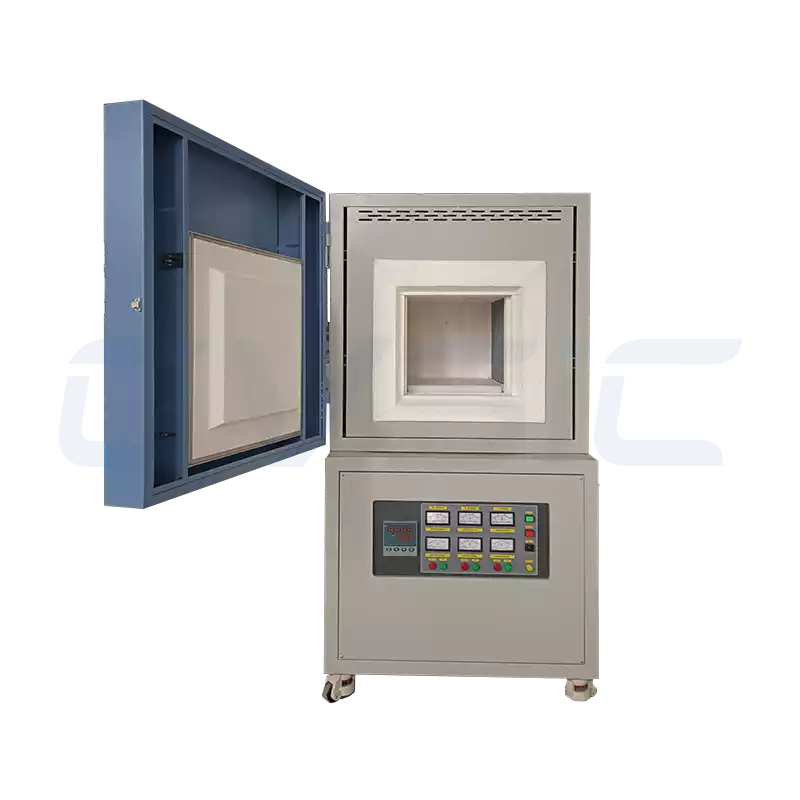

1800°C Small Muffle Furnace

1800°C High-Temperature Laboratory Muffle Furnace

The CVSIC 1800°C small muffle furnace features capacities of 1-12L, a maximum temperature of 1800°C, and an operating temperature of 1700°C, with precise control and a durable, energy-efficient design. Ideal for ultra-high-temperature sintering, heat treatment, and ashing. Global shipping available, starting from one unit!

- Name: CVSIC 1800°C Small Muffle Furnace

- Temperature: Maximum temperature of 1800°C, with stable operation at 1700°C

- Heater: U-shaped MoSi2 heating element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

CVSIC 1800°C small muffle furnace is designed for universities, research institutes, and small-scale mining and industrial enterprises. It achieves a maximum temperature of 1800°C and utilizes a polycrystalline mullite fiber chamber with molybdenum disilicide heating elements for reliable ultra-high-temperature performance.

Maximize your workspace and potential with flexible 1-12L chambers that fit even the tightest labs or small production floors. Seamlessly perform ultra-high-temperature sintering, melting, tempering, ashing, and heat treatments on metals or advanced materials. Accelerate your projects with rapid shipping, and tailor every order for unmatched precision and effectiveness.

Key Product Features

- Compact and Efficient: 1-12L small-capacity design, ideal for compact labs and benchtop setups.

- Ultra-High-Temperature Precision: Uses a durable temperature sensor and 50-step controls for steady 1700°C operation.

- Energy-Efficient and Durable: The special chamber and strong roof help save energy and last longer.

- Safe and Reliable: Overtemperature alarm, double-layer air-cooling (shell <60°C), and optional door designs.

- Flexible Customization: Adjust size, door types, and controls to fit your needs.

CVSIC 1800°C Small Muffle Furnace Features

- Ultra-High-Temperature Performance: Maximum of 1800°C and operating temperature of 1700°C, addressing extreme sintering and heat treatment demands.

- Compact Capacity Design: 1-12L chamber volumes, perfect for small-scale experiments while saving lab space.

- Energy-Efficient Operation: The special chamber keeps heat in, saving energy and reducing costs.

- Premium Heating Elements: U-shaped MoSi2 heating rods provide even heating and handle very high temperatures, making them good for complex material work.

- Intelligent Control: The 50-step automation system makes work easier and faster.

- Safety Features: Overtemperature alarm prevents overheating; double-layer air-cooled structure keeps the shell below 60°C.

- User-Friendly Operation: Customizable top- or side-opening doors keep operators away from heat sources for improved comfort.

- Durable Construction: The strong roof keeps its shape for reliable use, even over time.

CVSIC 1800°C Small Muffle Furnace Suitable Environments and Users

Operating Environments

- Compact Advanced Labs: Ideal for space-limited university or research institute labs in materials science, chemistry, or physics. The 1-12L compact design fits easily on workbenches, supporting ultra-high-temperature experiments.

- Ultra-High-Temperature Experimental Settings: Scenarios requiring 1800°C extremes, such as sintering and heat treatment of advanced ceramics, specialty alloys, or high-temperature composites, especially for small-batch samples.

- Teaching and R&D Labs: In universities or technical training centers for ultra-high-temperature material demonstrations or cutting-edge R&D, with simple operation suitable for students and researchers.

- Small Specialized Production Workshops: Such as high-performance ceramics workshops or specialty material processors, balancing cost and precision for small-batch ultra-high-temperature handling.

Target Users

- Materials Scientists: Focused on ultra-high-temperature material development, including sintering and performance testing of oxide ceramics, nitride ceramics, ultra-high-temperature alloys, or advanced composites.

- Chemistry Researchers: Conducting small-scale ultra-high-temperature compound decomposition, ashing, or thermal analysis experiments requiring precise temperature control.

- Small Business Owners: In precision ceramics, specialty alloys, or high-temperature material processing, prioritizing compact design, low energy use, and ultra-high-temperature performance.

- Educators: University or vocational trainers needing safe, user-friendly equipment for ultra-high-temperature experimental teaching.

- Startup R&D Teams: With limited budgets but requiring ultra-high-temperature tools, where 1-12L capacity and 2-9kW low power reduce operating costs.

Recommended Scenarios

- Sintering small quantities of advanced ceramics, such as zirconia, silicon carbide, or silicon nitride.

- Small-scale ultra-high-temperature alloy heat treatment to optimize properties, like in aerospace or high-temperature structural materials.

- Ashing analysis for high-precision organic or environmental sample testing.

- Ultra-high-temperature thermal decomposition experiments to study material behavior under extreme conditions.

CVSIC 1800°C Small Muffle Furnace Customization and Services

CVSIC provides versatile customization services, including:

- Chamber Sizes: Tailored from 1-12L or larger to align with your experimental requirements.

- Door Configurations: Options for top- or side-opening to enhance usability.

- Control Systems: Advanced programmable features adapted to specialized experimental protocols.

- Additional Features: Adjustments to heating elements or parameters based on applications.

Choose confidence—every furnace order is supported by prompt global delivery and expert technical consulting. Our commitment ensures you achieve seamless integration and peak results in every lab or production challenge you face.

Why Choose the CVSIC 1800°C Small Muffle Furnace?

- Brand Reliability: CVSIC specializes in one-stop solutions for global high-temperature industries.

- Ultra-High-Temperature Capability: 1800°C performance meets rigorous experimental standards.

- Compact and Efficient: 1-12L capacities fit small labs and production seamlessly.

- Energy-Saving and Durable: Optimized insulation and heating reduce consumption and extend service life.

- Flexible Customization: Comprehensive tailoring of sizes and functions for personalized needs.

- Global Service: Single-unit orders with fast delivery worldwide.

- Safe and Robust: Multi-layered safety designs protect operators and equipment.

Contact CVSIC today to customize your 1800°C small muffle furnace and elevate your research and production to new heights!

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1800°C Small Muffle Furnace

1800°C Industrial Muffle Furnace

- Name: CVSIC 1800°C Industrial Muffle Furnace

- Temperature: Maximum of 1800°C and operating temperature of 1700°C

- Heater: MoSi2 Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Large Muffle Furnace

- Name: CVSIC 1700°C Large Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

1700°C Medium Muffle Furnace

- Name: CVSIC 1700°C Medium Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

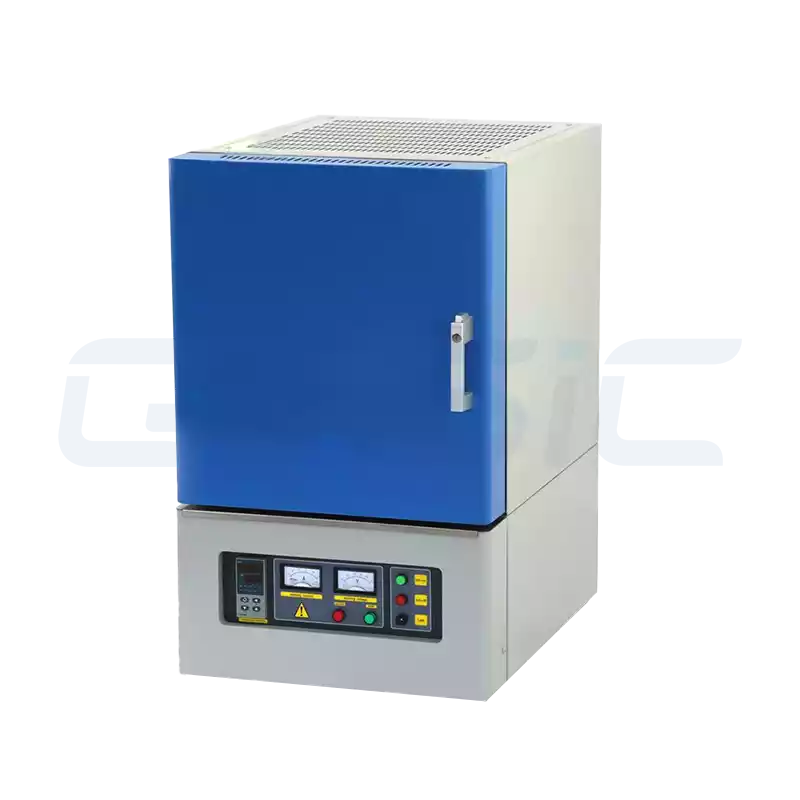

1700°C Small Muffle Furnace

- Name: CVSIC 1700°C Small Muffle Furnace

- Temperature: Maximum temperature of 1700°C, with stable operation at 1600°C

- Heater: MoSi2 Heating Element

- Size: customized according to customer requirements

- Packaging customization: Carton or wooden crate packaging

- Technical support: Provide selection advice, design and installation guidance

- MOQ: 1

- Services: OEM, ODM, Private Label

- Brand: CVSIC

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support