1Cr13Al4 Alloy Wire

1Cr13Al4 is a classic, budget-friendly FeCrAl resistance wire with solid stability and great value. Perfect for medium-temperature industrial heaters and electric heating elements. We offer custom specs and wholesale supply.

- Model: CV-0Cr21Al6

- Alloy Grade: 0Cr21Al6 (FeCrAl 216)

- Main Composition: Fe: Bal.; Cr: 20–22; Al: 5.0–7.0; Mo: ≤0.5

- Max Temp: 950°C

- Resistivity (20°C): 1.20-1.30 μΩ·m

- Density: 7.2 g/cm³

- Diameters: 0.1–7.0 mm

- Best Atmosphere: Air / Mildly oxidizing

1Cr13Al4 is a basic FeCrAl (iron-chromium-aluminum) resistance wire with about 13% chromium and 4% aluminum. It delivers the essential heat and oxidation resistance needed for industrial heating, while being easy to work with and very wallet-friendly.

It’s one of the most economical and widely used grades in the FeCrAl family, especially popular for medium-temperature electric heating applications.

Key Features of 1Cr13Al4

1Cr13Al4 is a medium-to-low alloyed FeCrAl resistance wire. With 13% Cr and 4% Al, it prioritizes ease of processing, low cost, and reliable performance at moderate temperatures.

- Lower resistivity — great for longer wire runs and easier voltage/current matching

- Fairly flat temperature coefficient — works well for steady medium-temp operation

- Less prone to thermal shock than high-aluminum FeCrAl grades

- Good ductility and flexibility

- Easy to draw, coil, and shape

- Low risk of cracking during cold forming

- Ideal for complex shapes or very thin wires

1Cr13Al4 is one of the most process-friendly FeCrAl alloys out there. It’s not built for extreme heat, but shines in stable, cost-sensitive heating applications.

CVSIC 1Cr13Al4 Alloy Specs

| Item | Details |

|---|---|

| Model | CV-1Cr13Al4 |

| Alloy Name | 1Cr13Al4 (economical FeCrAl resistance alloy) |

| Composition (%) | Fe: Bal., Cr 12–14%, Al 3.5–4.5% |

| Resistivity (20°C) | 1.20–1.30 μΩ·m |

| Max Operating Temperature | 950°C (in air) |

| Density | 7.2 g/cm³ |

| Melting Range | 1420–1450°C |

| Tensile Strength | 550–700 MPa |

| Elongation | 12–18% |

| Temp Coefficient of Resistance | 1.4–1.6×10⁻⁴ /°C |

| Oxidation | Good — suitable for continuous medium-temp use |

| Recommended Surface Load | 2–5 W/cm² |

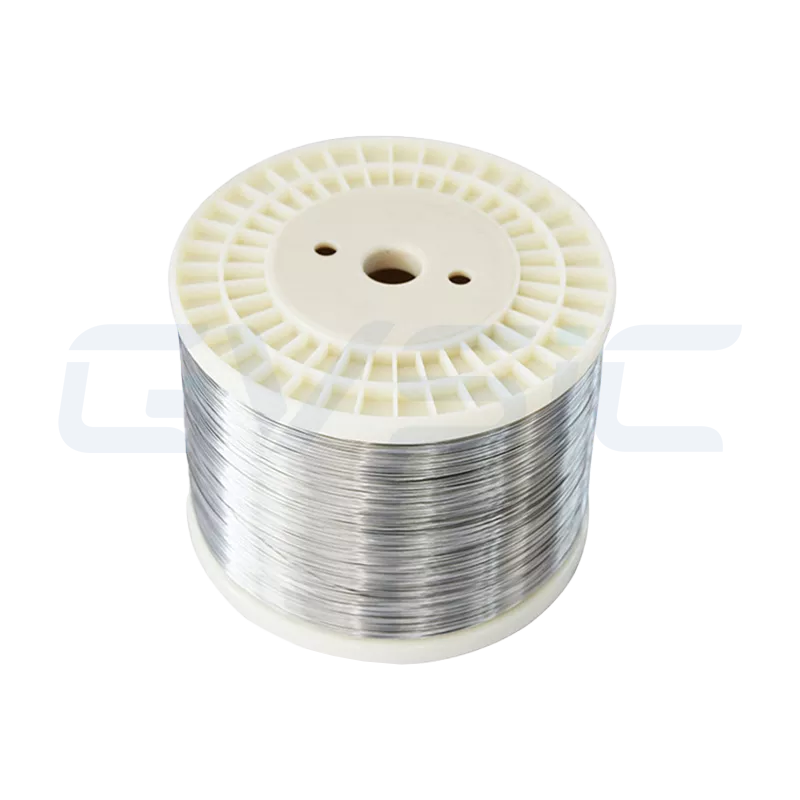

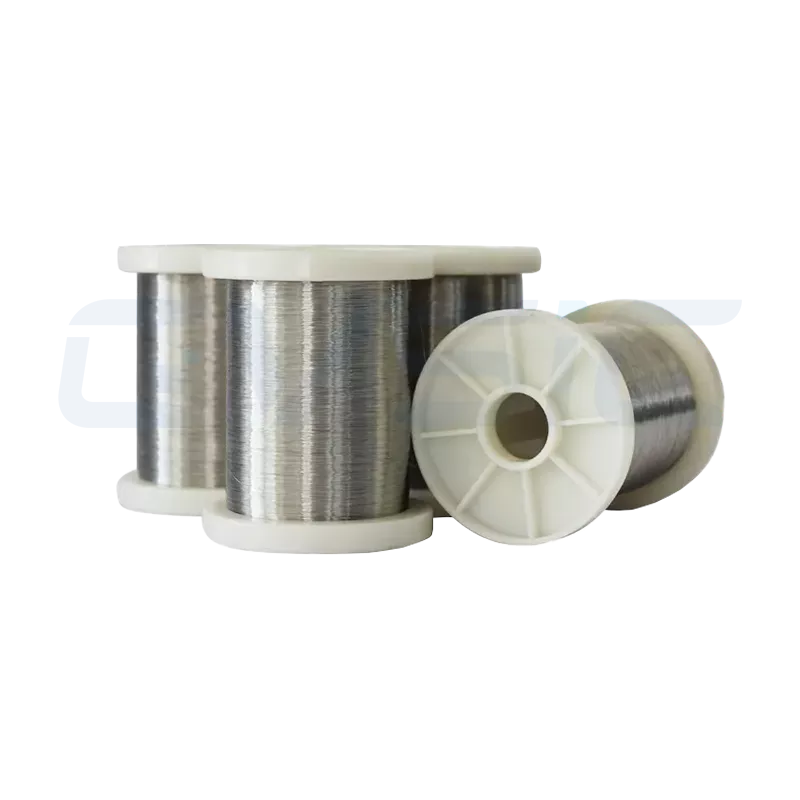

| Available Forms | Wire, flat strip, ribbon, coiled, seamless spools |

| Typical Applications | Industrial heating elements, ovens, drying equipment, medium-temp furnaces |

| Standout Traits | Low cost, reliable stability, easy to process, great for large-volume orders |

Because it has lower Cr and Al content, 1Cr13Al4 can’t reach the temperatures of premium FeCrAl grades, but it’s still plenty reliable for medium-heat jobs and saves you a lot on material cost.

Where 1Cr13Al4 Gets Used

1Cr13Al4 resistance wire is common in these areas:

- Industrial electric heating elements — heating wire, ribbons, or frames for medium-to-high temperature needs

- Heating equipment manufacturing — box furnaces, ovens, drying ovens, etc.

- Cost-sensitive heating devices — light industrial or commercial systems with moderate temperature requirements

- Standard heating parts supply — reliable source for consumable or standard components

Usage Tips & Limits

- Recommended continuous temperature ≤ 950–1000°C

- Not meant for long-term use above its rated temperature

- Oxidation speeds up noticeably at high temps or high surface loads

Quick tip: Keep the operating temperature and surface load in check — that’s the key to getting the longest life out of 1Cr13Al4.

How 1Cr13Al4 Compares to Other FeCrAl Alloys

| Feature | 1Cr13Al4 | 0Cr25Al5 | 0Cr27Al7Mo2 |

|---|---|---|---|

| Cr / Al Content | Low | High | Very high |

| Max Temperature | 950°C | 1250°C | 1400°C |

| Oxidation Resistance | Good | Very strong | Extremely strong |

| Service Life | Medium | Long | Very long |

| Cost | Lowest | Medium | Highest |

| Best For | Budget jobs | General high-temp | Extreme heat |

Quick selection guide:

- Tight budget + medium-high temp → 1Cr13Al4

- Standard high-temperature furnaces → 0Cr25Al5

- Ultra-high temp & tough conditions → 0Cr27Al7Mo2

Specs & Custom Options | B2B Supply

We offer full customization and wholesale for 1Cr13Al4 FeCrAl resistance wire:

- Wire diameters: Wide range available

- Supply forms: Coils / straight lengths / cut-to-size

- Processing: Coiling, forming, component assembly

- Business models: Wholesale / OEM / ODM

- Customers: Equipment makers, engineering firms, distributors

Wrap-Up | Great Value FeCrAl Resistance Wire

1Cr13Al4 FeCrAl resistance wire is a proven, reliable, and very cost-effective heating material. It’s an excellent choice for B2B customers who need decent temperature performance without breaking the bank, plus dependable supply.

Get in touch for pricing, samples, or help choosing the right material.

FAQs | 1Cr13Al4 Basics

How does 1Cr13Al4 differ from 0Cr25Al5?

1Cr13Al4 has lower Cr and Al, so it can’t handle as much heat, but it’s a lot cheaper — perfect when you want good value.

What’s the max temperature for 1Cr13Al4?

In air, keep long-term use under 950°C.

Can it run continuously?

Yes — fine for continuous operation at medium-high temps with reasonable surface load, but not for extreme heat.

Do you offer custom diameters and lengths?

Yes — we can make it to your drawings or specs.

Good for bulk orders?

Absolutely — stable supply and low cost make it ideal for large-volume purchases.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1Cr13Al4 Alloy Wire

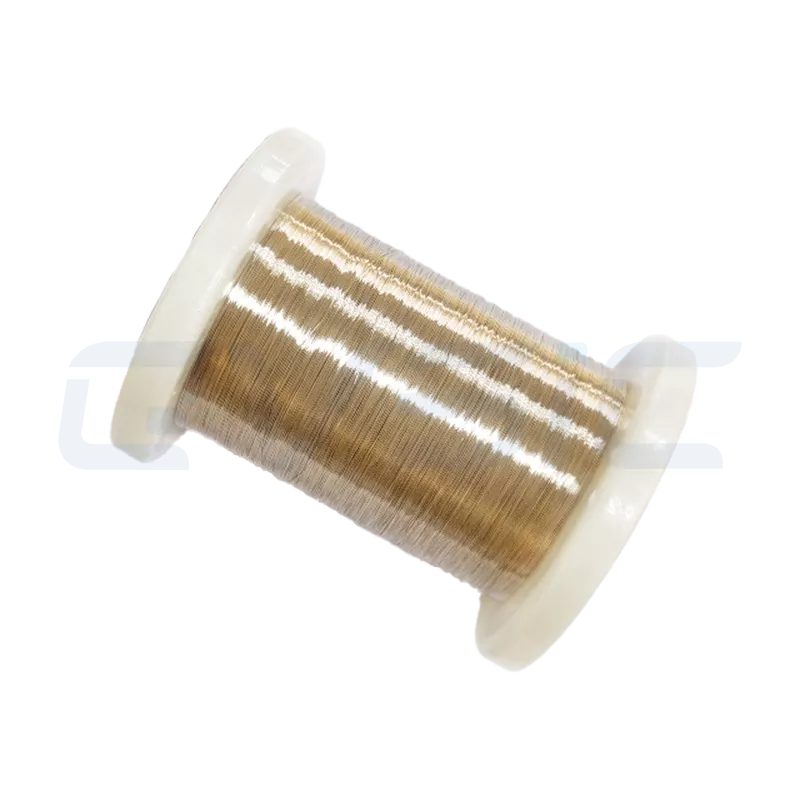

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

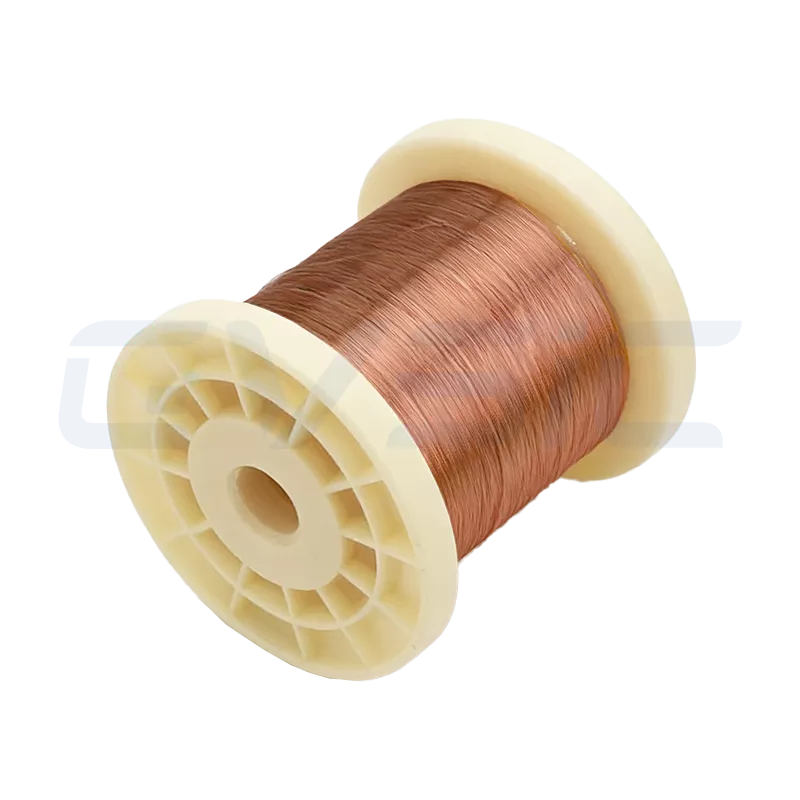

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support