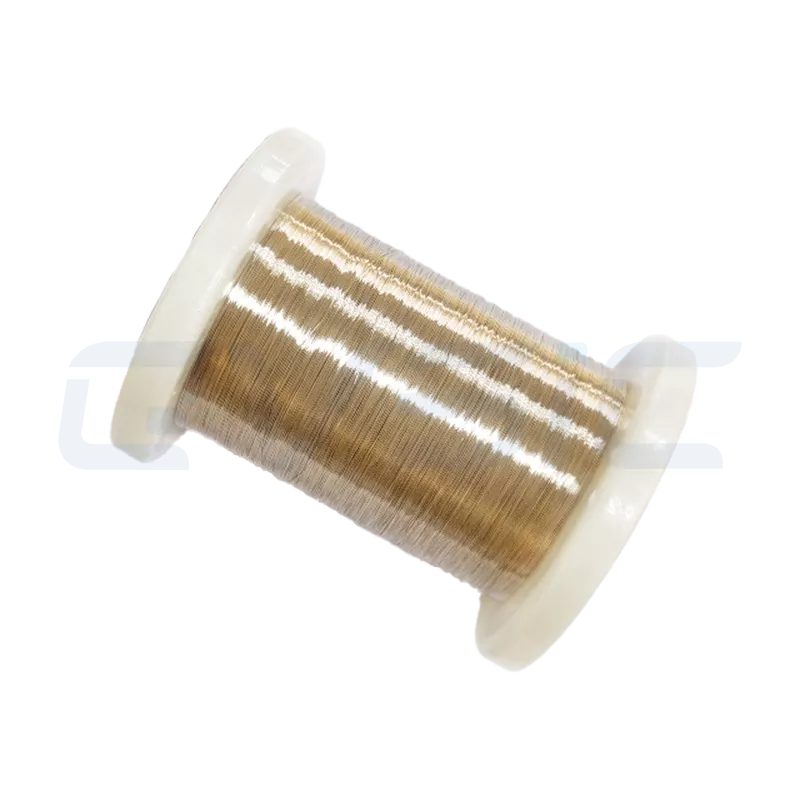

1cr20al3 Wire

1cr20al3 Alloy Heating Wire

1Cr20Al3 is a FeCrAl resistance wire with solid chromium levels and balanced aluminum—great oxidation resistance and stability in mid-to-high temps. Super common in industrial heating gear, and we handle custom orders plus wholesale.

- Model: CV-1Cr20Al3

- Alloy Grade: 1Cr20Al3 (FeCrAl low-aluminum resistance alloy)

- Main Composition: Fe: Bal., Cr 19–21%, Al 2.5–3.5%

- Max Temp: 1000–1100°C

- Resistivity (20°C): 1.25–1.35 μΩ·m

- Density: 7.2 g/cm³

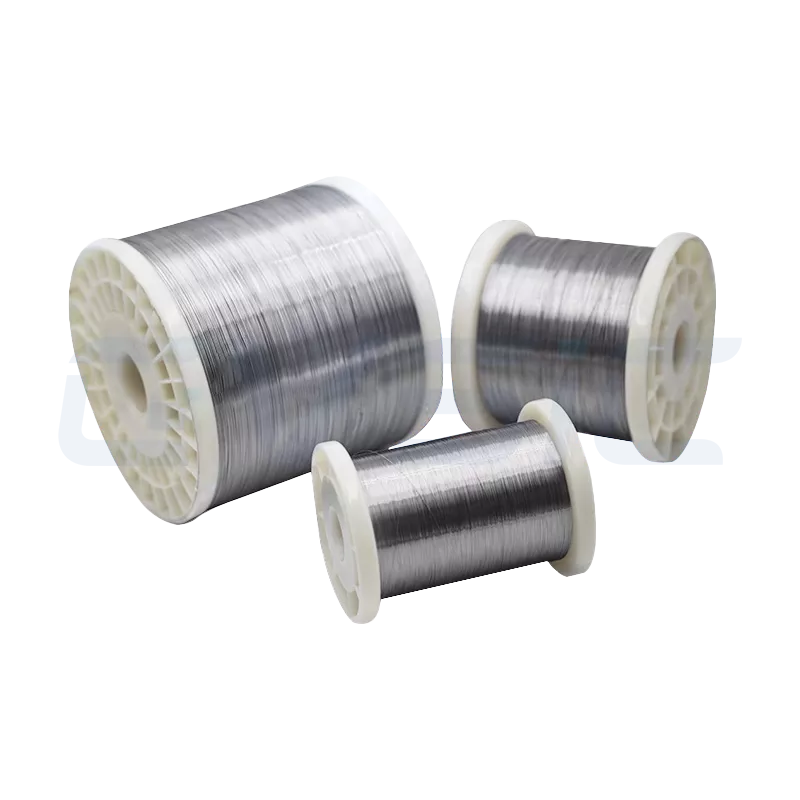

- Forms Available: Wire, flat strip, ribbon, coiled, seamless spools

- Best Atmosphere: Air / Mildly oxidizing

1Cr20Al3 resistance wire is a mid-temp FeCrAl (iron-chrome-aluminum) alloy with around 20% chromium (Cr) and 3% aluminum (Al). It boosts oxidation resistance and max temp while keeping costs reasonable.

It’s basically the upgraded version of 1Cr13Al4, but cheaper than 0Cr25Al5.

Key Features of 1Cr20Al3 Resistance Wire

Bumping chromium to 20% and dropping aluminum to 3% gives it a nice balance of oxidation protection and toughness.

- Way better at fighting oxidation than 1Cr13Al4—you can run it long-term at 1050°C easy.

- Oxide layer builds at just the right pace—not too thick or brittle—perfect for gear you turn on and off every day.

- Resistance stays pretty steady over time, so power output doesn’t drift—awesome for always-on stuff like drying tunnels or continuous annealing furnaces.

- A tad harder to work with than 1Cr13Al4 (higher Cr), but still no big deal.

CVISC 1Cr20Al3 Alloy Wire Specs

| Item | Details |

|---|---|

| Model | CV-1Cr20Al3 |

| Alloy Name | 1Cr20Al3 (FeCrAl low-aluminum resistance alloy) |

| Composition (%) | Fe: Bal., Cr 19–21%, Al 2.5–3.5% |

| Resistivity (20°C) | 1.25–1.35 μΩ·m |

| Max Temp | 1000–1100°C (air) |

| Density | 7.2 g/cm³ |

| Melting Range | 1420–1450°C |

| Tensile Strength | 550–700 MPa |

| Elongation | 12–18% |

| Temp Coefficient of Resistance | 1.4–1.6×10⁻⁴ /°C |

| Oxidation | Good—handles mid-temp continuous runs |

| Surface Load (Guide) | 2–5 W/cm² |

| Forms Available | Wire, flat strip, ribbon, coiled, seamless spools |

| Typical Uses | Heating tubes, rice cookers, heating sheets, hot plates, home appliance elements |

| Standout Traits | Affordable, reliable stability, easy to work with, great for big-volume mid-temp heating |

That 20% chromium helps it build a tougher oxide layer in mid-high heat air, so it lasts longer than 1Cr13Al4 under heavier loads and longer runs.

Where 1Cr20Al3 Resistance Wire Shines

You’ll find 1Cr20Al3 FeCrAl wire in spots like:

- Industrial furnaces and heaters: Wires, meshes, frames for mid-to-high heat jobs.

- Ovens and heat treatment gear: Gives even, steady heat.

- Always-on heating systems: Solid lifespan with proper loading.

- Bulk heating components: Perfect standardized material for big orders.

Usage Tips & Limits

Stick to ≤ 1100°C for best results: Going hotter risks the oxide layer not protecting well long-term.

Not for crazy high-power setups: It’s built for long life at mid temps, not pushing extremes.

How 1Cr20Al3 Compares to Other Alloys

| Feature | 1Cr13Al4 | 1Cr20Al3 | 0Cr25Al5 |

|---|---|---|---|

| Chromium | Low | Medium | High |

| Aluminum | Medium | Low-Medium | High |

| Max Temp | 950°C | 1100°C | 1250°C |

| Oxidation Resistance | Good | Strong | Top-Notch |

| Lifespan | Medium | Medium-Long | Long |

| Cost | Lowest | Medium | Higher |

Quick picks:

- Tight budget, mid temp → 1Cr13Al4

- Mid-high temp, steady runs → 1Cr20Al3

- Max heat & longevity → 0Cr25Al5

Specs & Custom Options | B2B Supply

We’ve got full custom and wholesale covered for 1Cr20Al3 FeCrAl wire:

- Diameters: Tons of options

- Supply: Coils, straight, cut-to-length

- Extra processing: Coiling, shaping, full components

- Models: Wholesale, OEM, ODM

- Customers: Manufacturers, engineers, distributors

Quality & Reliability

- Proven melting and drawing processes

- Tight control on resistivity consistency

- Precision checks on size and surface

- Steady batches for ongoing partnerships

Sweet Balance of Performance & Price in FeCrAl Wire

1Cr20Al3 FeCrAl resistance wire hits that perfect spot between solid performance, reliability, and cost—ideal for mid-to-high temp gear that runs around the clock.

Drop us a line for tech sheets, samples, or help choosing the right stuff.

FAQs | 1Cr20Al3 Basics

How’s 1Cr20Al3 better than 1Cr13Al4?

More chromium means way stronger oxidation resistance and higher heat tolerance.

What’s a safe long-term temp?

In air, keep it under 1100°C for steady long runs.

Good for non-stop industrial gear?

Yeah—runs stable continuously if you design the load right.

Can it swap in for some 0Cr25Al5 jobs?

Totally—great cheaper option when temps stay below 1200°C.

Custom specs and bulk orders?

You bet—built for B2B custom and long-term bulk.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To 1cr20al3 Wire

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support