Box-Type, Tube-Type, and External-Heat Atmosphere Furnaces Compared: Which One Suits Your Needs?

As an engineer, I know the importance of choosing the right atmosphere furnace. Box, tube, and external-heating furnaces…

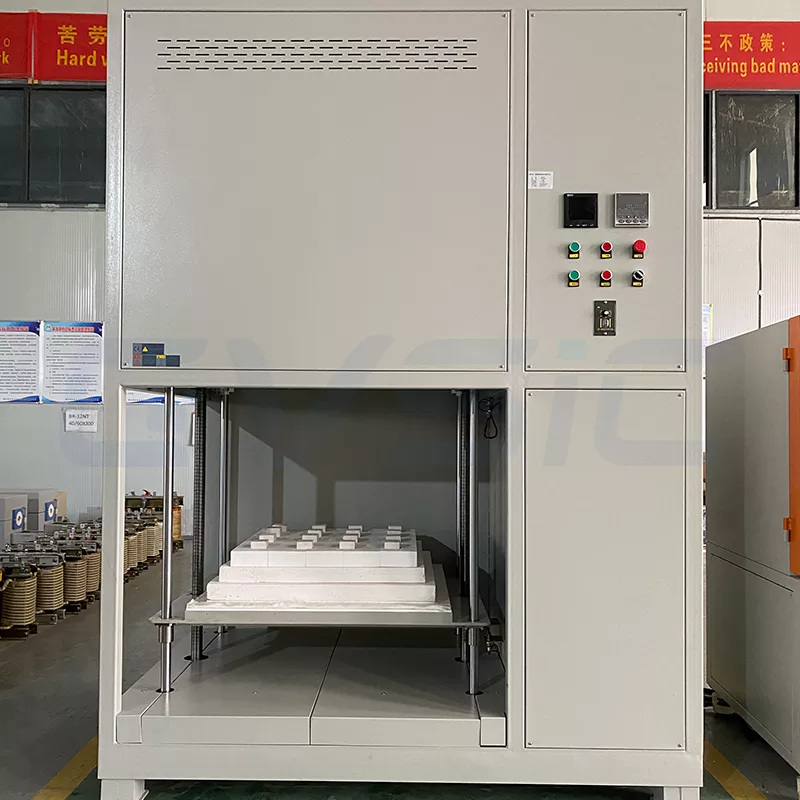

The Atmosphere Box Furnace supports temperatures from 1200°C to 1700°C, equipped with an alumina fibre furnace chamber and precise atmosphere control (N2, CO2, Ar), suitable for material laboratories and small-scale semiconductor production. Features high vacuum sealing and 50-segment intelligent temperature control, meeting global wholesale and customisation needs. Contact us now!

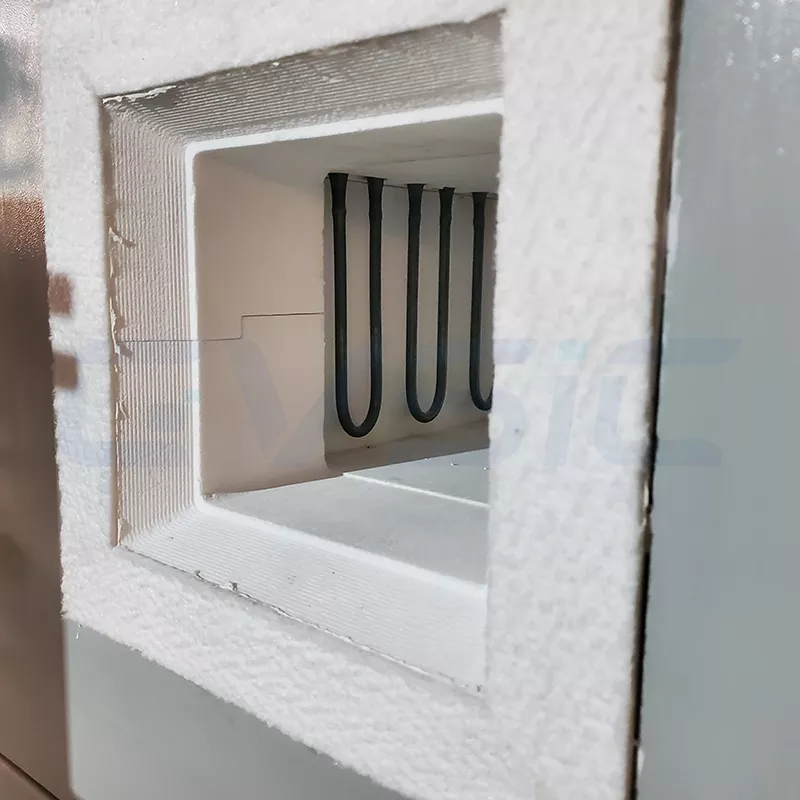

The CVSIC Box-Type Atmosphere Furnace is a high-performance thermal processing solution designed for precision heat treatment in controlled atmospheres. With a maximum temperature of 1700°C, this furnace supports inert gases (N₂, Ar, CO₂) and pre-vacuuming up to -0.08 MPa, creating an ultra-pure environment for sintering, annealing, and diffusion processes.

Equipped with high-purity alumina fiber insulation, intelligent PID temperature control, and robust chamber construction, it is widely adopted in material laboratories, semiconductor manufacturing, and pilot-scale production of silicon nitride ceramics, composites, and photovoltaic materials.

CVSIC offers comprehensive customisation services to ensure seamless integration with your production and R&D requirements:

Contact CVSIC to obtain customised box-type atmosphere furnace solutions tailored to your industry, supporting global wholesale and custom orders.

Note: Furnace chamber size, power, vacuum degree, and gas path systems can be customized to meet specific customer requirements. Contact us for detailed technical specifications.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

As an engineer, I know the importance of choosing the right atmosphere furnace. Box, tube, and external-heating furnaces…

With over 20 years of experience in high-temperature industrial applications, I understand the crucial role protective gases play…

Having worked in the high-temperature industrial sector for many years, I fully understand how heavily powder metallurgy (PM)…

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support