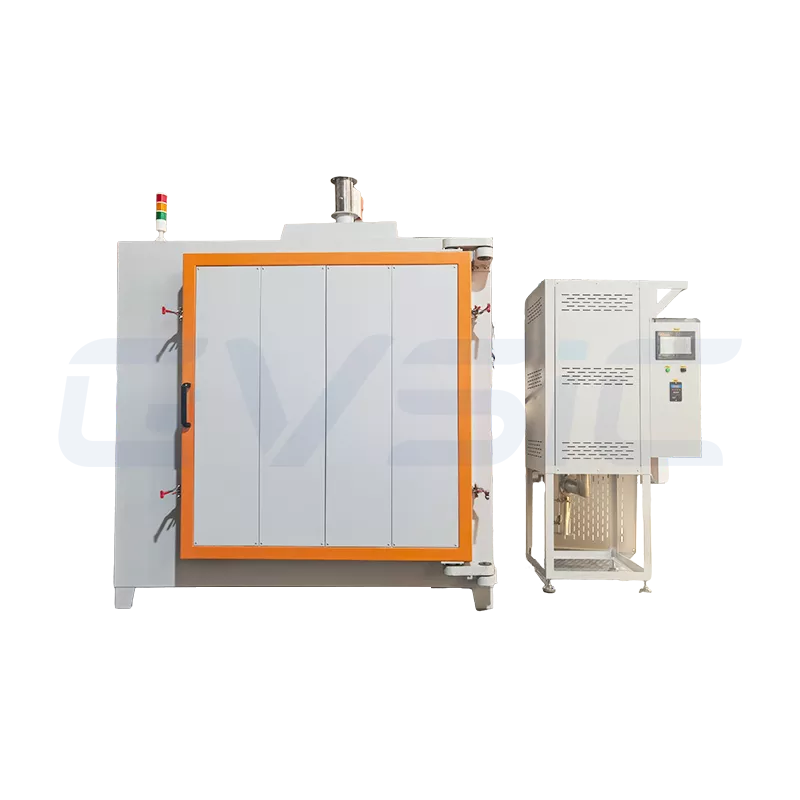

Bottom Loading Debinding and Sintering Furnace

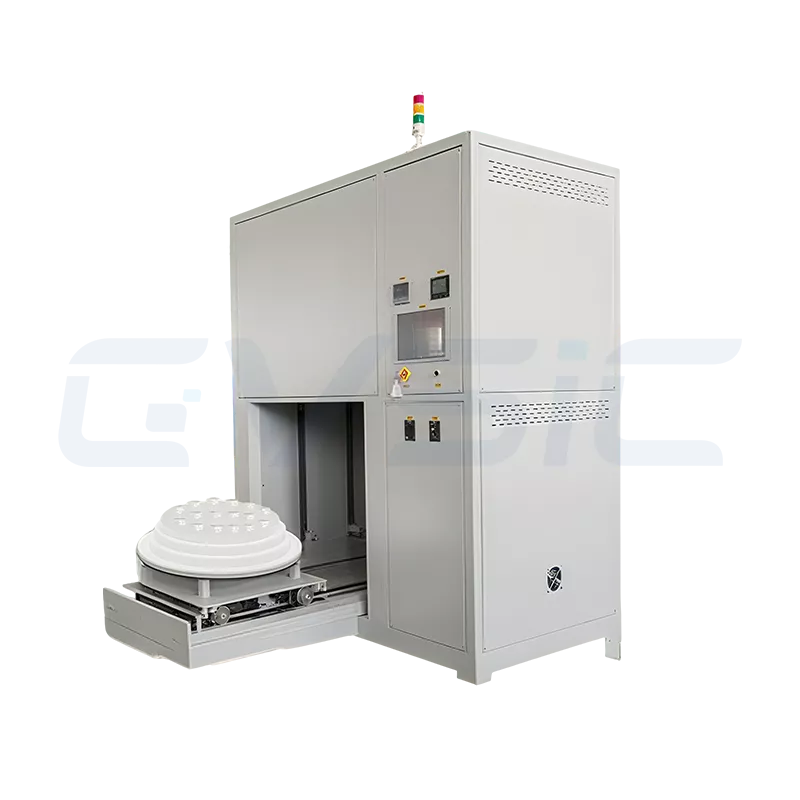

Lifting Debinding Sintering Furnace

CVSIC Bottom Loading Debinding and Sintering Furnace is specially designed for ceramic materials such as alumina and zirconia, with a maximum temperature of 1750°C. It integrates degreasing and sintering functions and has an intelligent lifting platform and uniform temperature field. It is suitable for research institutions, industrial and mining enterprises, and small-scale production, and offers customized solutions and global wholesale services

- Name: Degreasing and Sintering Furnace

- Furnace Lining: Ceramic Fiber

- Heating Elements: MoSi2 Heating Elements

- Maximum Temperature: 1750°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Process Applications: Degreasing Sintering, Heat Treatment

- Brand: CVSIC

The CVSIC Bottom Loading Debinding and Sintering Furnace is an advanced device specifically designed for the integrated degreasing and high-temperature sintering of ceramic materials such as alumina and zirconia. It is widely used in industrial and mining enterprises, research institutions, and university laboratories. The furnace features a high-purity alumina polycrystalline fiber furnace chamber and silicon molybdenum rod heating elements, reaching a maximum temperature of 1750°C. Through a four-sided heating layout and intelligent temperature control system, it achieves precise temperature control with a deviation of ±5°C, ensuring exceptional sintering quality.

The innovative loading design combines an intelligent lifting platform with a cart-style modular structure, equipped with an electric track drive system, enabling smooth and efficient material handling and significantly improving production efficiency throughout the degreasing and sintering process. The furnace body supports large-capacity loading, making it suitable for small-batch production of small to medium-sized components and material research and development needs, meeting the high standards of the ceramic, 3D printing, and advanced materials industries.

Debinding and Sintering Furnace Advantages

The CVSIC lift-type debinding and sintering furnace, equipped with advanced technology and user-centric design, offers the following core advantages:

- Precise temperature field control: A four-sided silicon molybdenum rod heating layout controls temperature differences within ±5°C, guaranteeing consistent and high-quality sintered products.

- Wide temperature range: Supports temperatures from room temperature to 1750°C, meeting diverse material sintering requirements.

- Efficient loading/unloading design: An intelligent lifting platform and cart-style modular structure are equipped with an electric track drive and fully automatic material handling carts, simplifying operations and enhancing production efficiency.

- High-durability furnace chamber: Constructed from vacuum-formed high-purity alumina polycrystalline fiber, it offers high-temperature resistance, corrosion resistance, low thermal mass, resistance to rapid cooling/heating, excellent insulation performance, and significant energy-saving benefits.

- Advanced temperature control system: Equipped with industrial-grade 0.2-class intelligent instruments, PID regulation, 50-segment programmable heating curves, a high-definition touchscreen, and a PLC automatic control system, offering intuitive operation and high automation.

- Stable lifting system: Combines a three-phase asynchronous motor with a worm gear lift (linear guide), ensuring precise positioning and smooth operation. Equipped with limit switches and self-locking functionality to ensure safety and reliability.

- Efficient exhaust and cooling: Variable-frequency fans support operation under slight negative or atmospheric pressure, equipped with an air preheating system (up to 400°C) to accelerate organic vaporization and reduce degreasing time by 30%-50%. Mullite alumina ceramic exhaust ports are corrosion-resistant and quickly vent exhaust gases.

- Safety features: Equipped with over-temperature alarms, thermocouple failure alarms, and safety limit switches to ensure operational safety.

- Optional dual-cart configuration: Supports alternating use of track-mounted dual carts to meet continuous production requirements.

CVSIC Debinding and Sintering Furnace Technical Specifications

| Parameter | Details |

|---|---|

| Max. Temperature | 1750℃ (≤2 hours) |

| Working Temperature | 800–1700℃ |

| Temperature Control System | 1. PLC touchscreen control with real-time temperature/current curve recording 2. Programmable heating/cooling rate and dwell time 3. Thermocouple break/over-temperature protection 4. Over-temperature alarm, enabling unattended operation |

| Temperature Accuracy | ±1℃ |

| Heating Rate | 0–15℃/min |

| Thermocouple | Type B, 99.7% alumina protection tube |

| Heating Elements | MoSi2 Heating Elements |

| Chamber Structure | Three-layer ceramic fiber insulation: 1. 1800℃ ceramic fiber board 2. 1600℃ ceramic fiber board 3. 1260℃ ceramic fiber board |

| Furnace Body Design | Double-layer steel casing + dual cooling fans, external surface temperature < 60℃ |

| Door Structure | Bottom-lift door with auto power cut-off for safety |

| Power Supply | 110V or 220V, 50/60Hz, single phase (customizable) |

| Warranty & Service | 1. 1-year limited warranty + lifetime technical support 2. Consumables (e.g., thermocouples) not covered 3. Damage caused by corrosive/acidic gases not covered |

| Certification | CE Certified |

Note: Furnace chamber dimensions, power, and other configurations can be customized according to customer requirements. Please get in touch with us for detailed technical specifications.

Application Scenarios

The CVSIC lifting degreasing and sintering furnace is suitable for the following industries and processes:

- Ceramic industry: degreasing and high-temperature sintering ceramic materials such as alumina and zirconia.

- 3D printing: degreasing and sintering processes for ceramic 3D-printed parts.

- Research and development: sintering experiments and testing new materials (such as composite and nanomaterials).

- Industrial and mining enterprises: High-temperature sintering and heat treatment of small and medium-sized components.

- Laboratory applications: High-precision material research in universities and research institutions.

This furnace type provides an ideal solution for customers requiring efficient, precise, and flexible heat treatment equipment suited for small-batch production and R&D scenarios.

Application Notes

- Not recommended for use with toxic or explosive gases without proper safety measures.

- Furnace chamber is made of refractory ceramic; minor cracks may occur after long-term use, which is normal and can be repaired with an alumina coating.

- Avoid using corrosive or acidic gases to prolong the lifespan of both the chamber and heating elements.

Customization Services

CVSIC offers comprehensive customization services to ensure seamless integration with your production and R&D needs:

- Chamber dimensions and capacity: Customized internal dimensions and volume based on production scale to accommodate varying loading requirements.

- Temperature Configuration: Customizable temperature ranges of 1700°C or 1750°C to suit specific processes.

- Air Inlet and Exhaust Systems: Customizable air preheating systems or exhaust gas cracking systems to optimize degreasing efficiency and environmental performance.

- Control Systems: Customizable PLC, touchscreen interfaces, and RS232/RS485 software to enhance automation and data monitoring capabilities.

Optional Accessories

- Mullite/Corundum Pads: Enhance load-bearing capacity and durability within the furnace.

- Air Preheating/Exhaust Gas Cracking System: Provide enhanced treatment solutions tailored to specific exhaust gas characteristics.

- Dual Cart System: Support continuous production for maximum efficiency.

- Global Support: Provides installation guidance, operational training, and maintenance services to ensure the stable, long-term operation of the equipment.

Contact CVSIC to obtain customized Bottom Loading Debinding and Sintering Furnace solutions tailored to your industry, supporting global wholesale and custom orders.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Bottom Loading Debinding and Sintering Furnace

Hot Air Circulation Debinding Furnace

- Name: Hot Air Circulation Debinding Furnace

- Furnace Chamber: Stainless Steel Chamber

- Heating Element: Resistance Wire

- Maximum Temperature: 650°C

- Operating Temperature: 600°C

- Vacuum Level: Non-Vacuum

- Available Atmosphere: Inert Atmosphere (N₂, CO₂, Ar₂, etc.)

- Application Processes: Sintering, Debinding Sintering, Heat Treatment

Debinding and Pre-Sintering Integrated Furnace

- Name: Debinding and Pre-Sintering Integrated Furnace

- Furnace Chamber: Ceramic Fiber

- Heating Elements: Resistance Wire, SiC Heating Elements

- Maximum Temperature: 650°C, 1200°C

- Voltage: 380V

- Vacuum System: None

- Available Atmosphere: Inert atmosphere (N₂, CO₂, Ar₂, etc.)

- Process Applications: Sintering, Brazing, Debinding Sintering, Heat Treatment, Annealing

Lifting Atmosphere Sintering Furnace

- Name: Atmosphere debinding and sintering furnace

- Furnace chamber: Ceramic fiber

- Heating elements: MoSi2 heating elements

- Maximum temperature: 1700°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Available Atmosphere: Inert Gas (N₂, CO₂, Ar₂)

- Applications: Degreasing Sintering, Heat Treatment

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support