Ceramic Fiber Safety and Environmental Compliance Guidelines

In high-temperature industries, ceramic fiber is highly valued for its thermal insulation and temperature resistance. Customers often ask,…

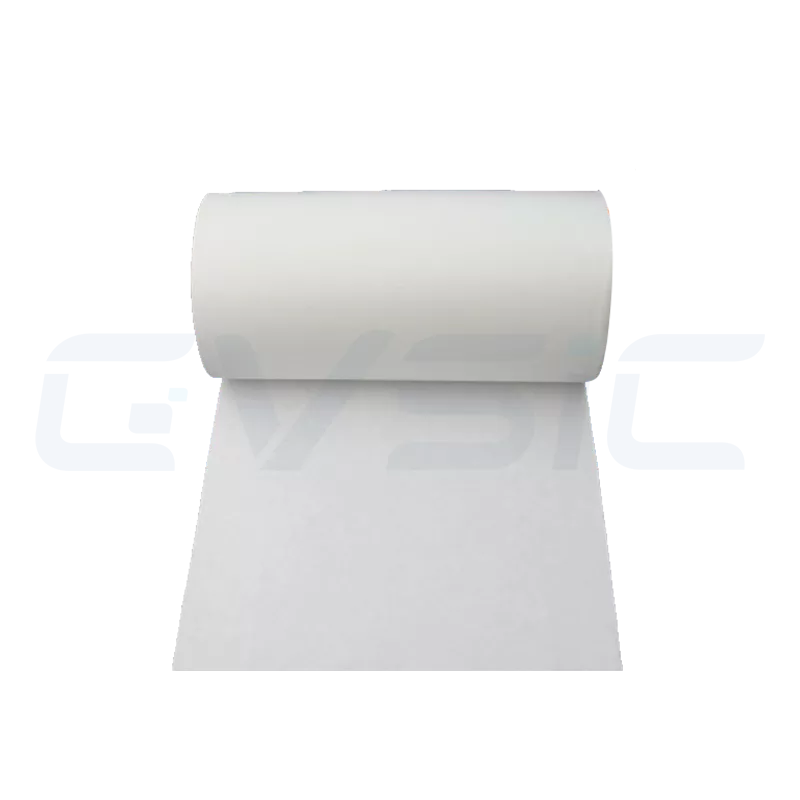

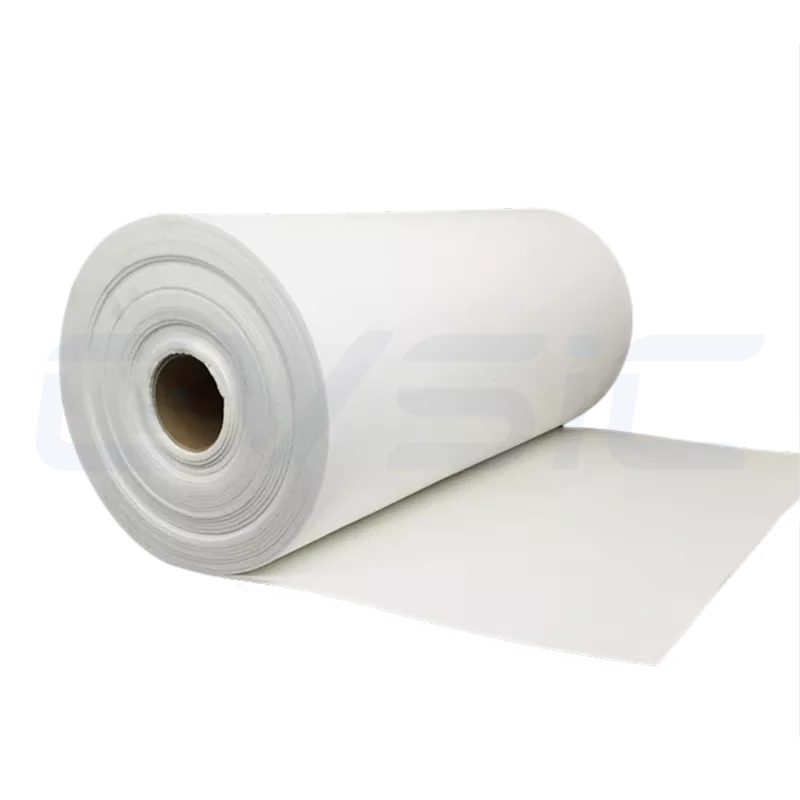

CVSIC Ceramic Fiber Paper offers exceptional thermal and electrical insulation properties, capable of withstanding temperatures up to 1600°C. It is suitable for ceramics, glass, metallurgy, and automotive industries. Custom sizes and packaging are available, with global wholesale supply. Contact us for efficient thermal insulation solutions!

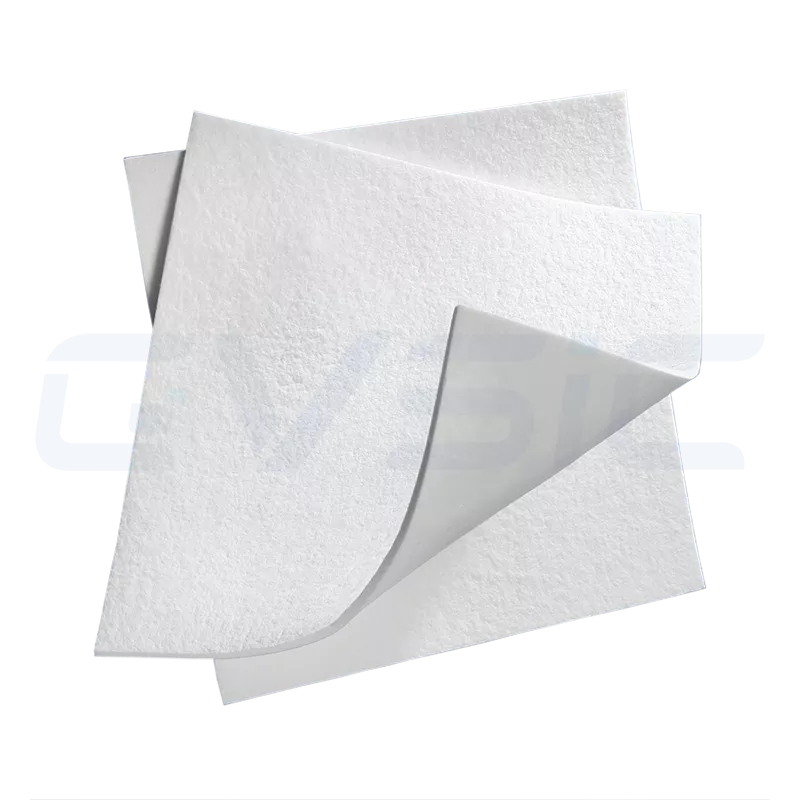

CVSIC Ceramic Fiber Paper is made from high-purity alumina-silica ceramic fiber cotton as the primary raw material, combined with an appropriate amount of binder, and manufactured using a wet-forming process. It features uniform thickness, a smooth surface, and high flexibility.

The product series covers five temperature grades: 1260°C, 1350°C, 1400°C, 1430°C, and 1600°C. It exhibits excellent chemical stability and can resist most corrosive chemicals. Even after exposure to oil, water, or steam, its temperature resistance, thermal insulation, and dielectric properties remain unchanged after drying.

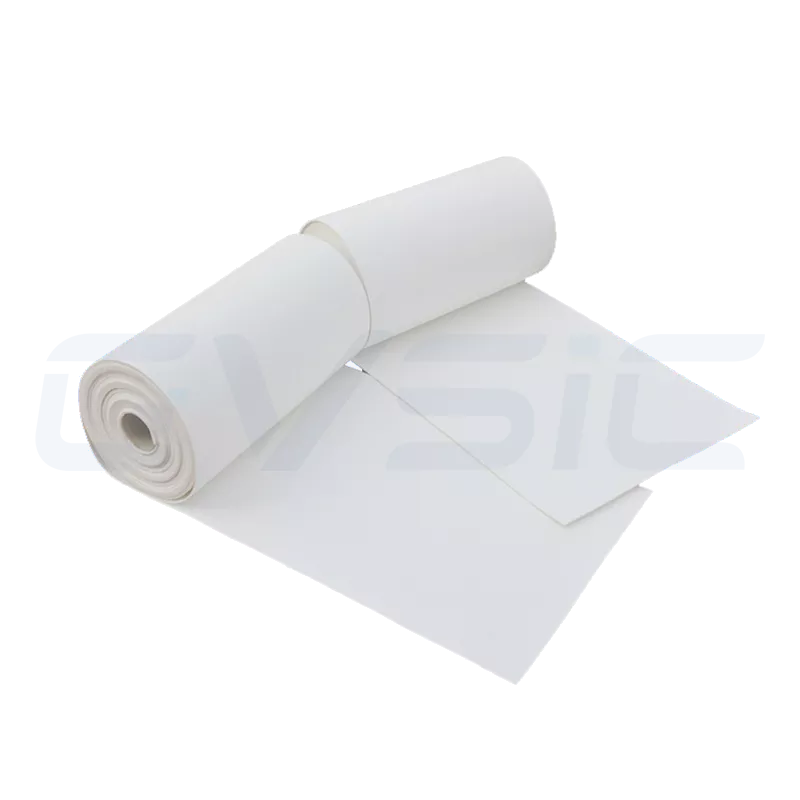

Due to its ease of processing into various finished products through cutting or stamping, it is widely used in high-temperature insulation, electrical insulation, and sealing applications across industries such as ceramics, glass, metallurgy, chemicals, automotive, and home appliances.

CVSIC ceramic fiber paper is widely applied in the following fields:

CVSIC offers comprehensive customization services for ceramic fiber paper to meet your specific needs:

Contact us immediately for customized solutions and quotes for CVSIC ceramic fiber paper, optimizing your high-temperature and electrical insulation applications!

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

In high-temperature industries, ceramic fiber is highly valued for its thermal insulation and temperature resistance. Customers often ask,…

In high-temperature industries, ceramic fibre blankets provide essential insulation, fire protection, and noise reduction for vital equipment. As…

In high-temperature industries, equipment must operate steadily and efficiently while minimizing energy loss. Ceramic fiber meets these challenges…

Selecting the right ceramic fiber is crucial for high-temperature industries due to its thermal insulation and heat resistance.…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support