How to choose the right ceramic fiber product for your project?

Selecting the right ceramic fiber is crucial for high-temperature industries due to its thermal insulation and heat resistance.…

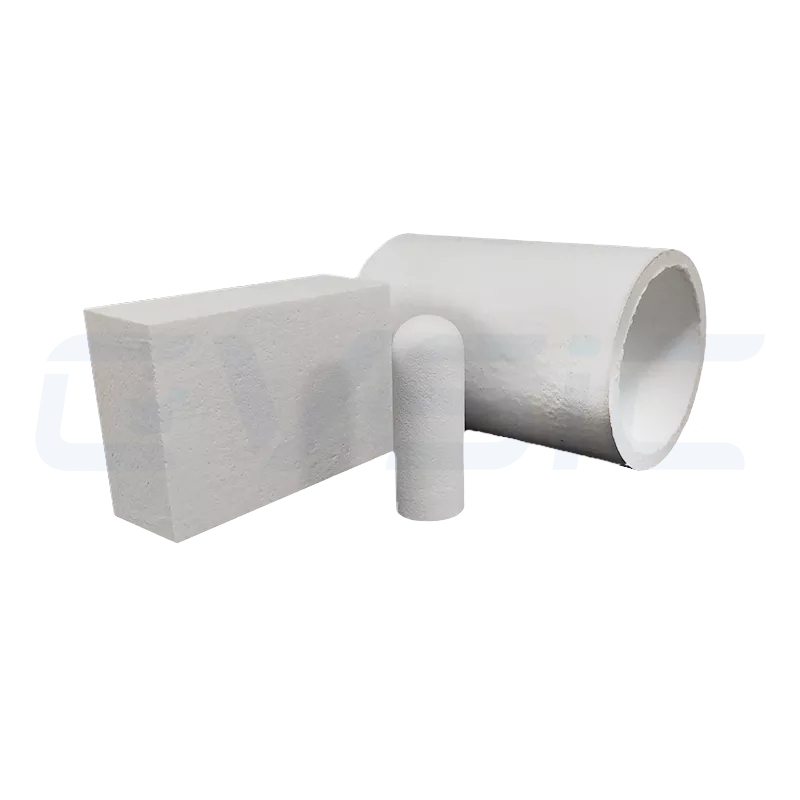

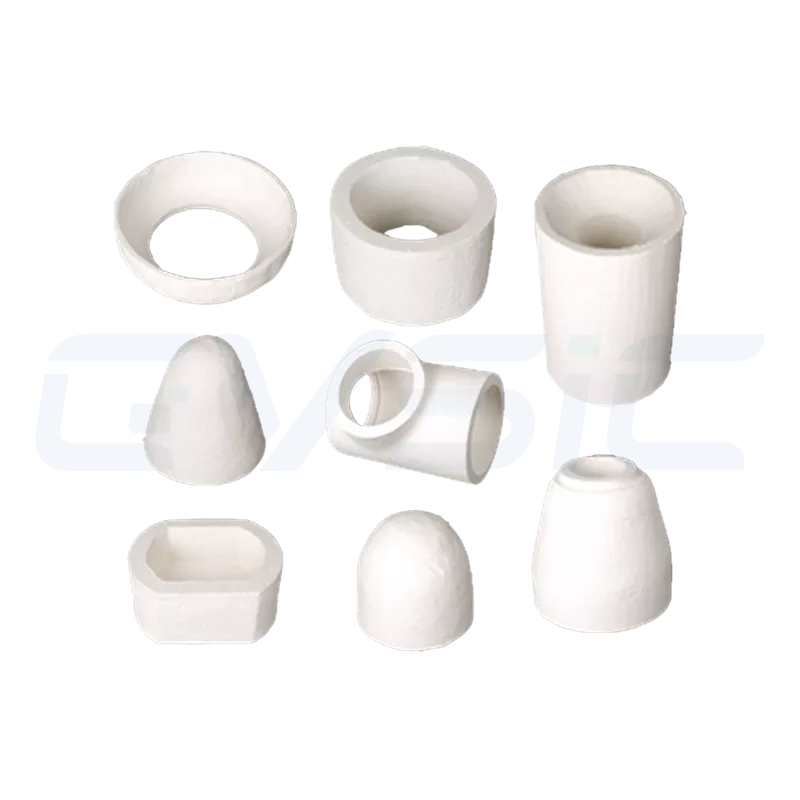

CVSIC Ceramic Fiber Vacuum Formed Shapes withstand temperatures up to 1800°C, offering high strength and precise insulation. They suit industrial furnaces, aluminum products, and laboratory furnace linings. Custom shapes and packaging are available, with global wholesale supply. Contact us for efficient insulation solutions!

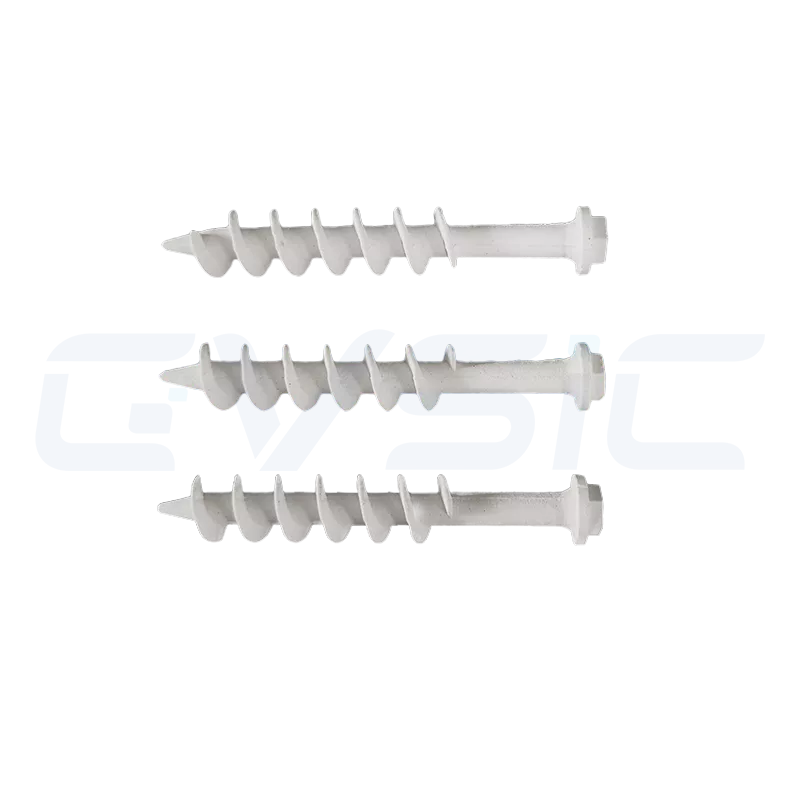

CVSIC Ceramic Fiber Shaped Parts are made from high-purity ceramic fiber cotton using vacuum forming technology. They offer superior high-temperature performance and rigid structural strength, specifically designed for special insulation requirements in industrial applications.

The product range covers seven temperature grades: 1260°C, 1350°C, 1400°C, 1430°C, 1600°C, 1700°C, and 1800°C. Custom shapes and dimensions can be tailored to meet customer specifications, ensuring high precision.

Within their applicable temperature range, these custom-shaped products exhibit low shrinkage, high thermal insulation, lightweight properties, and impact resistance, making them easy to cut or process. They also offer excellent wear and peel resistance, and can withstand corrosion from most molten metals. The products support surface curing agents or refractory mortar coatings to enhance corrosion and erosion resistance.

CVSIC ceramic fiber custom-shaped products are widely used in the following fields:

CVSIC offers comprehensive customization services for ceramic fiber specialty products to meet your specific needs:

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Selecting the right ceramic fiber is crucial for high-temperature industries due to its thermal insulation and heat resistance.…

In the world of high-temperature industries, heat is both a friend and a challenge. How can equipment maintain…

In high-temperature industries, selecting the right insulation material is akin to choosing the ‘best armour’ for equipment. As…

In high-temperature industrial projects, ceramic fiber provides excellent thermal insulation and resistance. Selecting compatible adhesives, anchors, and other…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support