Ceramic Holders for MoSi2 Heaters

MoSi2 heating element ceramic clamp

CVSIC Ceramic Holders for MoSi2 Heaters, made of insulating ceramic and stainless steel, works with 3/6mm to 12/24mm sizes, handles up to 1900℃, and allows easy external setup. Offering global wholesale, customization, and OEM/ODM services. Contact us for free samples!

- Materials: Insulating ceramic (high-density alumina or ceramic fibre) and stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts, two insulating ceramic plates

- Diameters: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Temperature: Up to 1900℃

- Appearance: White ceramic plates, high-temperature resistant; silver stainless steel clips, smooth

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for Molybdenum Disilicide (MoSi2) heating elements (U-type, W-type, L-type, straight)

- Advantages: Tough enough for extreme heat, corrosion-resistant, supports external installation, handles thermal expansion and contraction with ease

- Inventory: In stock

- After-Sales Service: Global service center support

Ceramic Holders for MoSi2 Heaters Description

CVSIC Ceramic Holders for MoSi2 Heaters is built to secure Molybdenum Disilicide (MoSi2) heating elements, crafted from high-density insulating ceramic (alumina or ceramic fibre) and corrosion-resistant stainless steel, complete with stainless steel angle brackets, hex nuts, hex bolts, and two insulating ceramic plates.

It fits MoSi2 elements with diameters of 3/6 mm, 4/9 mm, 6/12 mm, 9/18 mm, and 12/24 mm, enduring temperatures of up to 1900℃, making it ideal for high-temperature furnaces, kilns, and industrial heating applications. Its unique design lets you install MoSi2 elements from outside the stove, making operation a breeze, handling thermal expansion and contraction with ease, reducing stress, and boosting element lifespan. In stock, packed in cartons for safe shipping, and widely used in ceramics, electronics, and lithium battery industries.

Ordering Information

When ordering Ceramic Holders for MoSi2 Heaterss, please provide the following parameters:

- MoSi2 Element Diameter: 3/6mm, 4/9mm, 6/12mm, 9/18mm, or 12/24mm

- Example: Ceramic clamp for 6/12mm MoSi2 element, denoted as: Ceramic Clamp/6/12mm

- Note: Custom specs are available to ensure perfect compatibility with MoSi2 elements.

Ceramic Holders for MoSi2 Heaters Connection Method

- Installation Position: The ceramic clamp secures MoSi2 heating elements to the top of furnaces or kilns, facilitating external installation by attaching to the element’s aluminium-coated cold end.

- Connection Method:

- Place the aluminium braid on the MoSi2 cold end’s aluminium coating.

- Secure the aluminium braid around the cold end with stainless steel clips, placing two ceramic plates on both sides or in the centre to block heat.

- Attach the clamp to the furnace top using stainless steel angle brackets, hex bolts, and nuts, ensuring the element hangs vertically with the conical transition zone (g) inside the furnace.

- During initial setup, don’t over-tighten bolts; after about 48 hours of heating, re-tighten bolts to address thermal relaxation, ensuring connection end voltage <0.01V.

- Note: Ceramic plates must fully cover the cold end connection area to prevent heat transfer to the clamp; regularly check bolt tightness to avoid poor contact and overheating.

Ceramic Holders for MoSi2 Heaters Application Fields

CVSIC Ceramic Holders for MoSi2 Heaterss are widely used in:

- High-Temperature Furnaces: Supports element fixation in box furnaces, tunnel furnaces, and muffle furnaces, especially for external installation setups.

- Electronic Semiconductors: Ensures stable connections for wafer sintering, diffusion furnaces, and encapsulation processes.

- Lithium Battery Materials: Facilitates element suspension for high-temp processing of anode and cathode materials.

- Ceramics and Glass Manufacturing: Maintains stability in high-temp sintering or melting processes.

- Laboratory Furnaces: Meets fixation needs for high-temp experiments and material testing.

Ceramic Holders for MoSi2 Heaters Product Advantages

- Harsh Enough for Extreme Heat: High-density insulating ceramic outperforms metal clamps in extreme conditions, reaching temperatures of up to 1900℃.

- Corrosion Resistance: Ceramic and stainless steel materials resist oxidation and corrosion, suitable for various atmospheres (e.g., O2, N2).

- External Installation: The unique design enables the installation of MoSi2 elements from outside the furnace, making it ideal for complex furnace types.

- Thermal Isolation: Insulating ceramic plates shield the cold end from heat, extending the lifespan of the element and clamp.

- Easy Installation and Replacement: The design simplifies setup and removal and is compatible with various MoSi2 element types for user-friendly operation.

- Precise Compatibility: Fits 3/6mm to 12/24mm diameter MoSi2 elements, with diameter identifiers for accurate matching.

- Stock Availability: Standard specifications ship within 2-3 days; custom specifications are delivered within 7-30 days.

- Global Service: ISO-certified factory, 360-ton annual capacity, offers free samples with no minimum order quantity.

Ceramic Holders for MoSi2 Heaters Installation Method

To ensure the performance and safety of Ceramic Holders for MoSi2 Heaterss, follow these steps:

- Inspect Components: Check that stainless steel clips, ceramic plates, angle brackets, bolts, and nuts are undamaged and match the MoSi2 element’s diameter identifier.

- Secure Element: Place the aluminium braid on the MoSi2 cold end’s aluminium coating, with stainless steel clips securing it, and ceramic plates placed on both sides or centrally to block heat.

- Vertical Suspension: Attach the clamp to the furnace top using stainless steel angle brackets and hex bolts, supporting external installation, ensuring the element hangs vertically with the conical transition zone (g) inside the furnace.

- Initial Fastening: Tighten bolts lightly to avoid lateral stress on the component.

- Post-Heat Check: After 48 hours of furnace operation, re-tighten bolts to address thermal relaxation, ensuring connection end voltage <0.01V.

- Maintenance Check: Regularly check clamp and bolt tightness to prevent loosening or damage from overheating.

- Note: Installation must be performed by professionals, avoiding lateral force and over-compression. Contact us to download the installation manual for detailed guidance and instructions.

Design Recommendations

- Diameter Matching: Select a clamp that matches the MoSi2 element’s cold end diameter (3/6mm to 12/24mm), verifying the identifier numbers.

- Installation Space: Ensure sufficient furnace top clearance, with elements at least three times the hot end diameter from the furnace walls or bottom, to support external installation layouts.

- Thermal Isolation: The ceramic plates must completely cover the cold end connection area. Keep the furnace top temperature below 300℃ to prevent clamp overheating.

- Temperature Control: Utilize an SCR voltage regulator (for precise current control) to prolong the lifespan of the clamp and element.

- Regular Maintenance: Check bolt tightness within 48 hours of initial operation to prevent poor contact or element breakage.

- Compatibility: Clamps are compatible with U-type, W-type, L-type, straight, and other MoSi2 elements, making them adaptable to various furnace designs.

Customization Services

CVSIC offers flexible customization for Ceramic Holders for MoSi2 Heaterss:

- Size Customization: Tailored to MoSi2 element diameters (3/6mm to 12/24mm).

- OEM/ODM Services: Support bulk wholesale, free samples, no minimum order quantity, and delivery in 7-30 days.

- Special Coatings: Offer oxidation- or corrosion-resistant coatings for better high-temp performance.

- Technical Support: Provide expert guidance and thermal field simulation from selection to setup.

- Contact us for customized solutions or to request complimentary samples.

CVSIC is focused on delivering top-notch MoSi2 ceramic clamps to optimize fixation performance in high-temp furnaces, electronics, lithium batteries, and more, with easy external installation. Contact us for product quotes and customization services or to request free samples that can help enhance your heating efficiency.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Ceramic Holders for MoSi2 Heaters

MoSi2 Heating Element two Shank Holders

- Materials: Insulating ceramic (high-density alumina ceramic) and stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts, two insulating ceramic blocks

- Diameters: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Appearance: Silver stainless steel clips, smooth white ceramic blocks, high-temperature resistant

- Voltage: 110-480V

- Packaging: Carton

- Advantages: Handles extreme heat, is corrosion-resistant, easy to install, supports thermal expansion and contraction

- Inventory: In stock

- Product Category: MoSi2 heating element accessory

- After-Sales Service: Global service center support

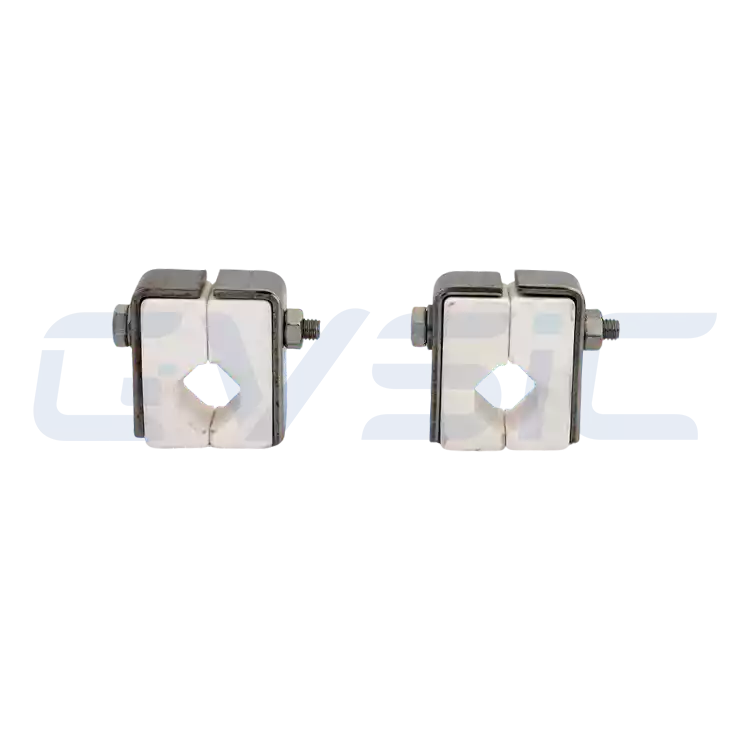

MoSi2 Heating Element Single Shank Holders

- Material: Stainless steel (heat-resistant steel)

- Components: Stainless steel angle brackets, hex nuts, hex bolts

- Diameter Compatibility: 3/6mm, 4/9mm, 6/12mm, 9/18mm, 12/24mm

- Appearance: Silver, smooth

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for various MoSi2 heating elements (U-type, W-type, L-type, straight)

- Advantages: High-temperature resistant, corrosion-resistant, flexible installation, easy operation

- Product Category: MoSi2 heating element accessory

- Origin: China

- Minimum Order Quantity: 10 pieces

- Inventory: In stock

- After-Sales Service: Global service center support

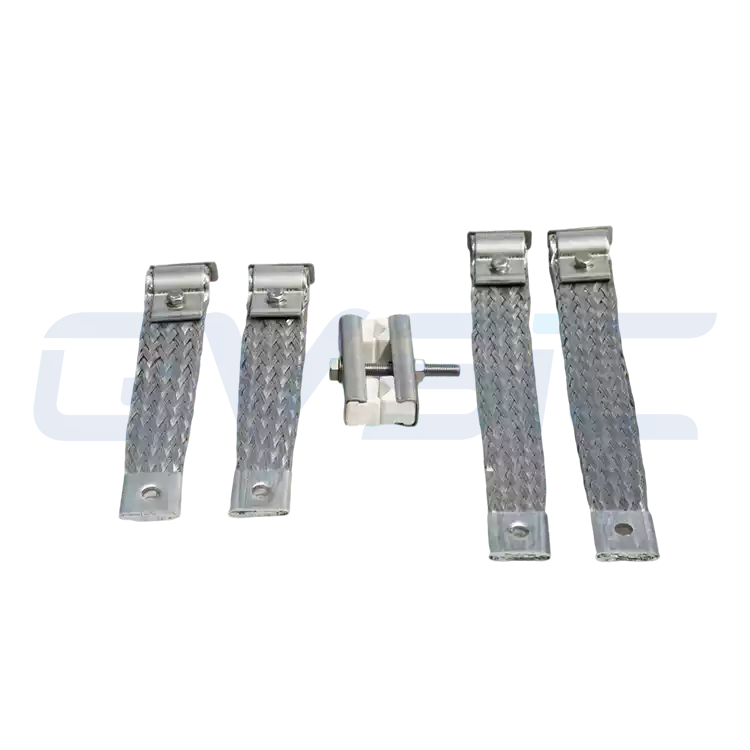

Mosi2 Heating Element Plate Holders

- Materials: High-density alumina ceramic (Al₂O₃) and corrosion-resistant stainless steel (heat-resistant steel)

- Components: Hex nuts, hex bolts, two insulating ceramic plates

- Diameters: 3/6mm, 4/9mm

- Temperature: Up to 1900℃

- Appearance: Silver stainless steel clip, smooth; white ceramic plates, high-temperature resistant

- Voltage: 110-480V

- Packaging: Carton

- Applications: Suitable for various Molybdenum Disilicide (MoSi2) heating elements (U-type, W-type, L-type, straight)

- Advantages: Handles extreme heat, corrosion-resistant, easy to install, supports thermal expansion and contraction

- Product Category: Molybdenum Disilicide (MoSi2) heating element accessory

- Inventory: In stock

- After-Sales Service: Global service center support

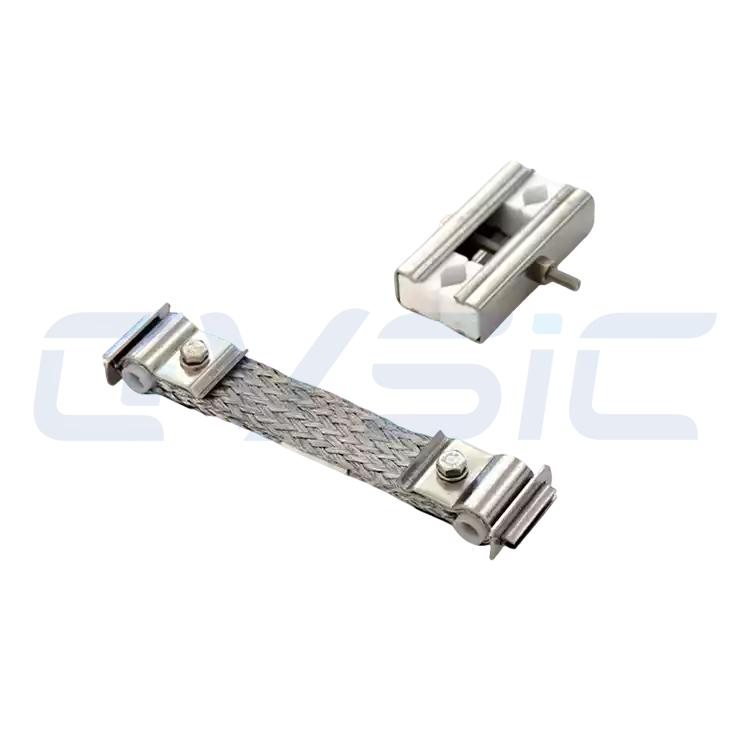

Mosi2 Heating Element Combination Straps

- Materials: Aluminum foil and stainless steel (heat-resistant steel)

- Current: 25-800A

- Width: 8-50mm

- Thickness: 1-3.5mm

- Single Wire Diameter: 0.15-3mm

- Length: Customizable

- Appearance: Smooth, bright, flexible

- Electrical Property: High conductivity

- Product Category: Furnace spare part

- Applications: High-temperature furnaces, heating testing equipment

- Inventory: In stock

- Origin: China

- Packaging: Carton or export wooden crate

- After-Sales Service: Global service center support

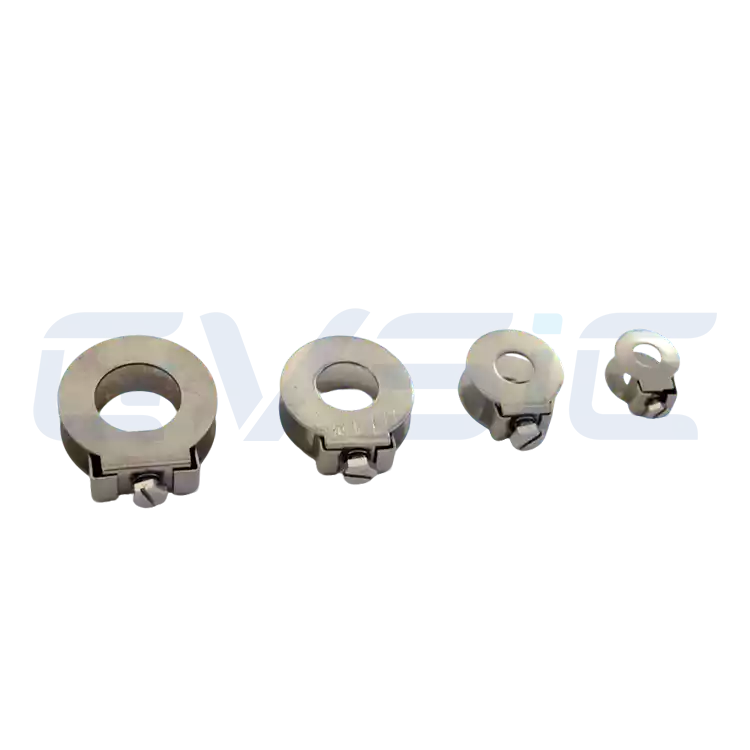

MoSi2 Heating Elements C Contact Clamp

- Materials: High-quality stainless steel and heat-resistant spring steel

- Sizes: Diameters 6mm, 9mm, 12mm

- Thickness: 2mm

- Voltage: 110-480V

- Appearance: Silver, smooth

- Packaging: Carton

- Advantages: Corrosion-resistant, high-temperature resistant, rust-free, rapid heating, long lifespan, easy installation and maintenance

- Usage: Used with aluminum braid to secure MoSi2 cold-end aluminum coating for efficient conductivity

- Product Category: MoSi2 heating element accessory

- Inventory: In stock

- Origin: China

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support