Cr15Ni60 Alloy Wire

Nichrome 60/15 Alloy Wire

Cr15Ni60 is a mid-nickel NiCr resistance wire that nails the balance of cost, performance, and reliability. Great for all kinds of industrial electric heating setups with solid oxidation resistance and steady runs. We handle B2B custom and bulk.

- Model: CV-Cr15Ni60

- Alloy Grade: Nichrome 60/15

- Main Composition:Ni: 55–61%, Cr: 15–18%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.12 μΩ·m

- Density: 8.2 g/cm³

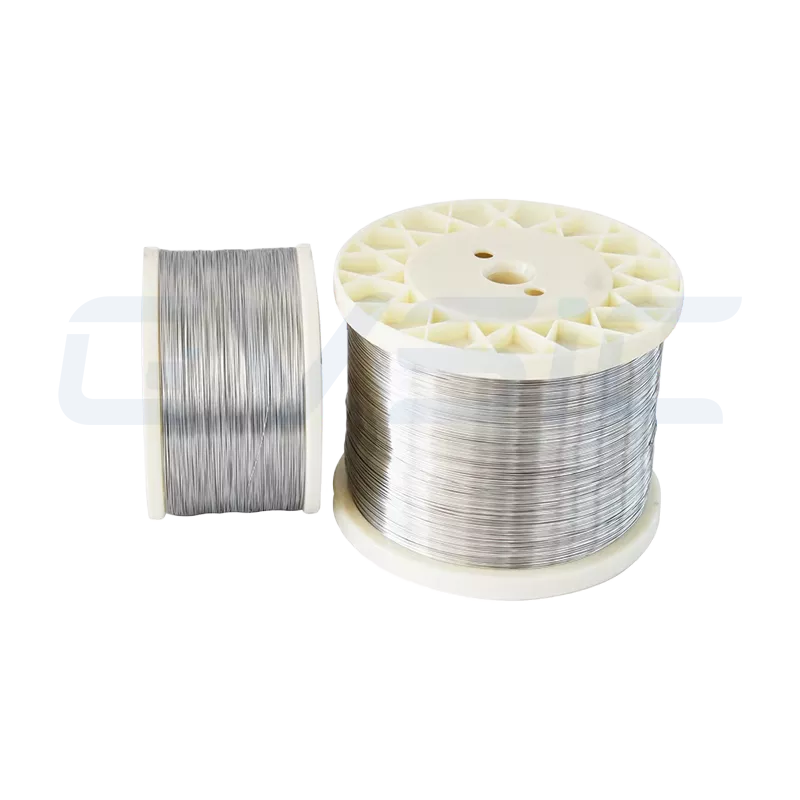

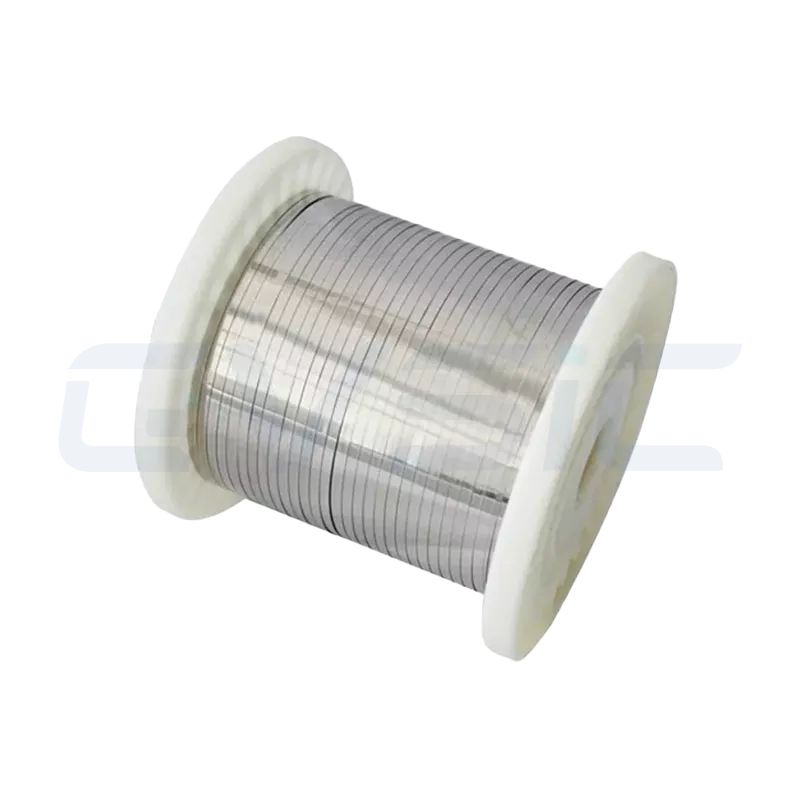

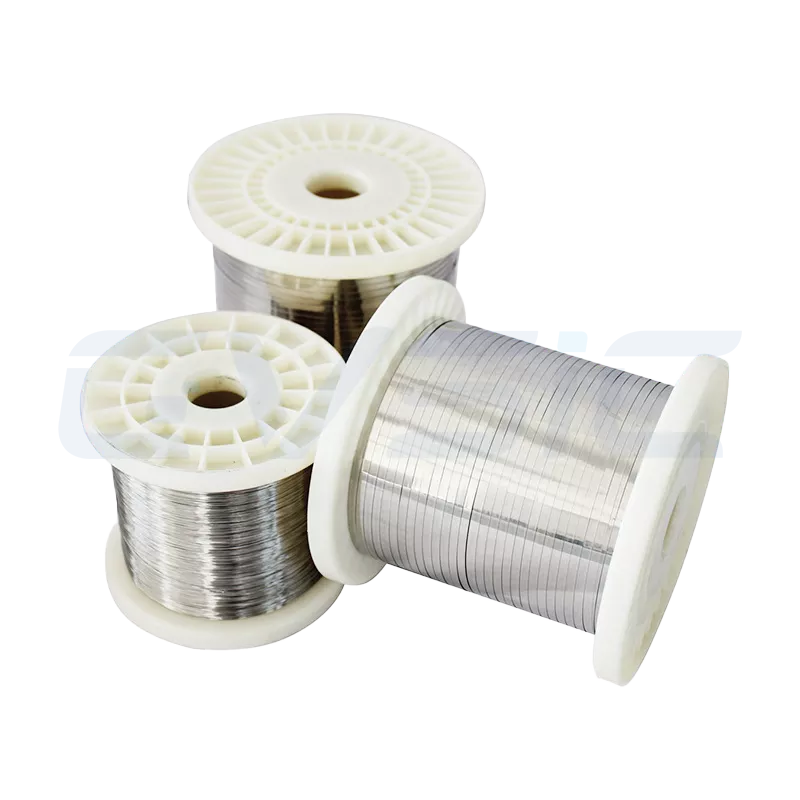

- Forms Available: Wire, strip, flat; 0.03–8mm diameters; custom coiling

- Common Uses: Industrial furnaces, oven elements, heating tubes, mold heaters, durable wires

Cr15Ni60 is a mid-nickel NiCr resistance alloy wire built for affordable, dependable performance in industrial electric heating.

It’s the “sweet spot” grade in the NiCr (nickel-chrome) family for balancing performance and cost.

Typical mix is around 60% nickel (Ni) + 15% chrome (Cr), with clear engineering focus:

- No chase for max lifespan

- Keeps basic stability solid

- Delivers predictable, controllable, and wallet-friendly results in most industrial heating jobs

In real-world use, Cr15Ni60 is one of the most popular all-purpose NiCr materials out there.

Key Features of Cr15Ni60

Cr15Ni60 is a classic “steady Eddie” NiCr resistance alloy. It shines in reliability and ease, not pushing extreme temps.

- Around 60% nickel keeps it austenitic and tough at heat—good ductility, low chance of cracking from hot-cold cycles.

- Resistance shifts predictably—the curve stays smooth as temps rise, plays nice with temp controllers, and power adjustments are straightforward.

- Chrome at ≈15% is mid-level, builds a decent continuous Cr₂O₃ oxide layer—handles regular industrial temps fine, not super heavy-duty.

- Holds steady structure and resistance long-term in 900–1050°C, easy to predict lifespan.

- Processes like a dream—easy to coil, straighten, shape, that’s why lots of manufacturers love it.

All in all, Cr15Ni60 is that “reliable, low-drama” material for stable, controlled-power heating systems.

Cr15Ni60 (Nichrome 60/15) Specs Table

| Item | Value |

|---|---|

| Alloy Name | Cr15Ni60 |

| Equivalent | Nichrome 60/15, Ni60Cr15 |

| Common Alias | Ni60Cr15 (standard) |

| Composition (%) | Ni: 55–61%, Cr: 15–18%, Fe: Bal. |

| Max Temp | 1100°C |

| Resistivity (20°C) | 1.12 μΩ·m |

| Density | 8.2 g/cm³ |

| Thermal Conductivity | 45.2 KJ/m·h·°C |

| Expansion Coefficient | 17×10⁻⁶/°C |

| Melting Point | 1390°C |

| Elongation | >20% |

| Microstructure | Austenitic |

| Magnetic | Weakly magnetic |

| Standout Traits | Better strength/oxidation than 20/30 series—fits heavy-duty, longer-life gear |

| Common Uses | Industrial furnaces, oven elements, heating tubes, mold heaters, durable wires |

| Available | Wire, strip, flat; 0.03–8mm diameters; custom coiling |

At the same temp, Cr15Ni60 life depends heavy on surface load and supports—design matters more than the alloy sometimes.

Where Cr15Ni60 Resistance Wire Works Best

General industrial electric heating gear

- Heating wires, coils, strips

- Standard go-to for volume equipment

On-off or cycle-based systems

- Not always-on 24/7

- Manageable start-stop

OEM jobs watching cost and performance

- Big batches

- Cost-conscious but need steady runs

Mid-temp industrial furnaces and parts

- No need for insane life

- Focus on overall value

Usage Tips & Limits

Long-term continuous ≤ 1050–1100°C: Push higher and oxidation/cross-section loss speeds up fast.

Skip high-load designs: Thin wire + heavy power ages quick or snaps.

Good for steady runs, not rough stuff: Lots of fast hot-cold or overload cycles cuts life short.

Cr15Ni60’s Spot in NiCr Lineup

| Feature | Cr30Ni70 | Cr20Ni80 | Cr15Ni60 |

|---|---|---|---|

| Nickel | Super High | High | Medium |

| Chrome | High | Medium | Lower |

| Oxidation Fight | Top-Notch | Strong | Solid |

| High-Temp Strength | Rock Solid | Solid | Medium |

| Continuous Life | Extra Long | Long | Medium |

| Cost | Highest | Higher | Lower |

| Best For | Premium always-on | Continuous | General / on-off |

When reliability meets budget control, Cr15Ni60 is the smart, value-packed general NiCr pick.

Specs & B2B Custom Options

We handle standard and custom for Cr15Ni60 NiCr resistance wire:

- Diameters: Full industrial range

- Forms: Coils, straight, cut-to-length

- Processing: Coiling, shaping, full components

- Models: Wholesale, OEM, ODM

- Customers: Makers, element factories, engineering firms

Perfect for standard gear, volume projects, and repeat buyers.

Wrap-Up

Cr15Ni60 NiCr resistance wire wins on:

- Predictable behavior

- Sensible costs

- Fitting tons of industrial heating needs

If you’re aiming for: Reliable runs + budget-friendly + easy big buys — Cr15Ni60 is a practical, proven NiCr choice.

FAQs | Engineering Basics

Good for long-term high-heat continuous?

Yeah for continuous, but cap long-term at 1050–1100°C for predictable life.

Big diffs from Cr20Ni80?

Cheaper, but trades a bit on high-temp strength/oxidation—better for general or on-off jobs.

Okay for lots of start-stop?

Fine with smart loads, but skip high-frequency fast cycles.

Fit for volume OEM gear?

Totally—standard pick for tons of industrial stuff.

Custom specs and steady supply?

You bet—tailored bulk plans for your projects.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Cr15Ni60 Alloy Wire

Cr20Ni80 Heating Wire

- Model: CV-Cr20Ni80

- Alloy Grade: Ni80Cr20

- Main Composition: Ni: Bal., Cr: 20–23, Fe: ≤1%

- Max Temp: 1200°C

- Resistivity (20°C): 1.09 μΩ·m

- Density: 8.4 g/cm³

- Forms Available: Diameters: 0.018–10mm; Strips: 0.02–2mm; Custom tolerances

- Common Uses: High-temp furnaces, lab gear, ceramic sintering, cutting wires, appliance heaters

Cr30Ni70 Heating Wire

- Model: CV-Cr30Ni70

- Alloy Grade: NiCr70/30

- Main Composition: Ni: Bal. (about 70%), Cr: 28–31%, Fe: ≤1.0%

- Max Temp: 1200°C

- Resistivity (20°C): 1.18 μΩ·m

- Density: 8.1 g/cm³

- Forms Available: Diameters: 0.02–10mm (round) Strips: 0.02–2mm Custom flat wire, rods, coils

- Common Uses: Industrial furnace wires – High-temp elements – Ceramic heaters – High-temp ovens/tunnel kilns – Mold heating, lab furnaces

Cr20Ni35 Heating Wire

- Model: CV-Cr20Ni35

- Alloy Grade: Nichrome 35/20

- Main Composition:Ni: Cr: ≈20%, Ni: ≈35%, Fe: Bal.

- Max Temp: 1100–1150°C

- Resistivity (20°C): 1.02 μΩ·m

- Density: 8.0 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Mid-high temp industrial furnaces, ovens, heating tubes, durable elements

Cr20Ni30 Alloy Heatin Wire

- Model: CV-Cr20Ni30

- Alloy Grade: Nichrome 70/30, Ni70Cr30

- Main Composition:Ni: Cr: 18–21%, Ni: 30–34%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.04 μΩ·m

- Density: 7.9 g/cm³

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Heaters, electric tubes, hair dryer wires, damping/cutting wires (foam/plastic)

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support