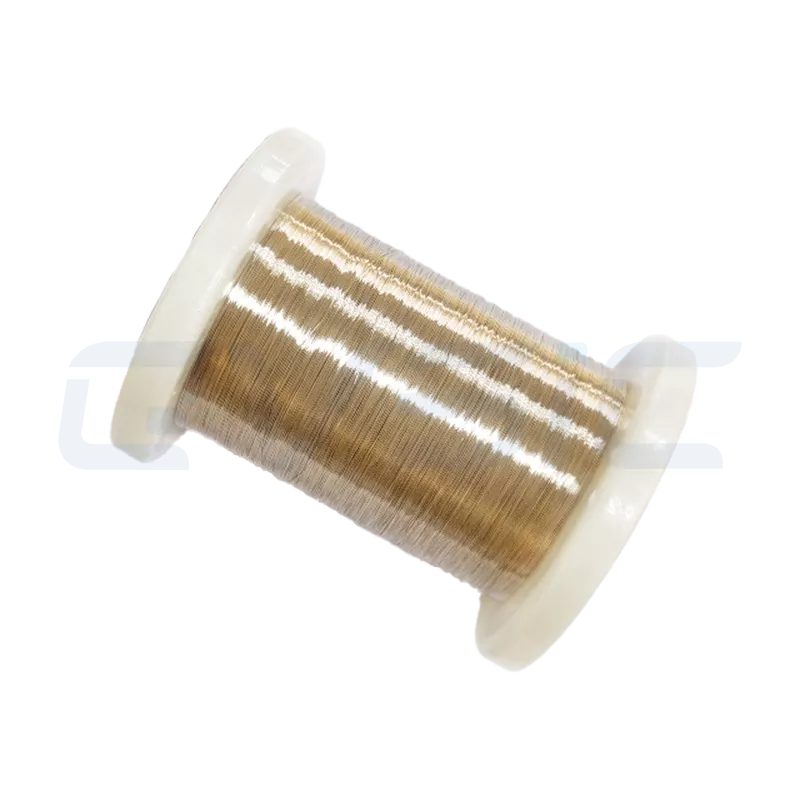

Cr20Ni30 Alloy Heatin Wire

Cr20Ni30 is a low-nickel high-chrome NiCr resistance wire that boosts oxidation resistance with more chromium. Great for mid-temp industrial electric heating. We support B2B custom, OEM, and bulk.

- Model: CV-Cr20Ni30

- Alloy Grade: Nichrome 70/30, Ni70Cr30

- Main Composition:Ni: Cr: 18–21%, Ni: 30–34%, Fe: Bal.

- Max Temp: 1100°C

- Resistivity (20°C): 1.04 μΩ·m

- Density: 7.9 g/cm³

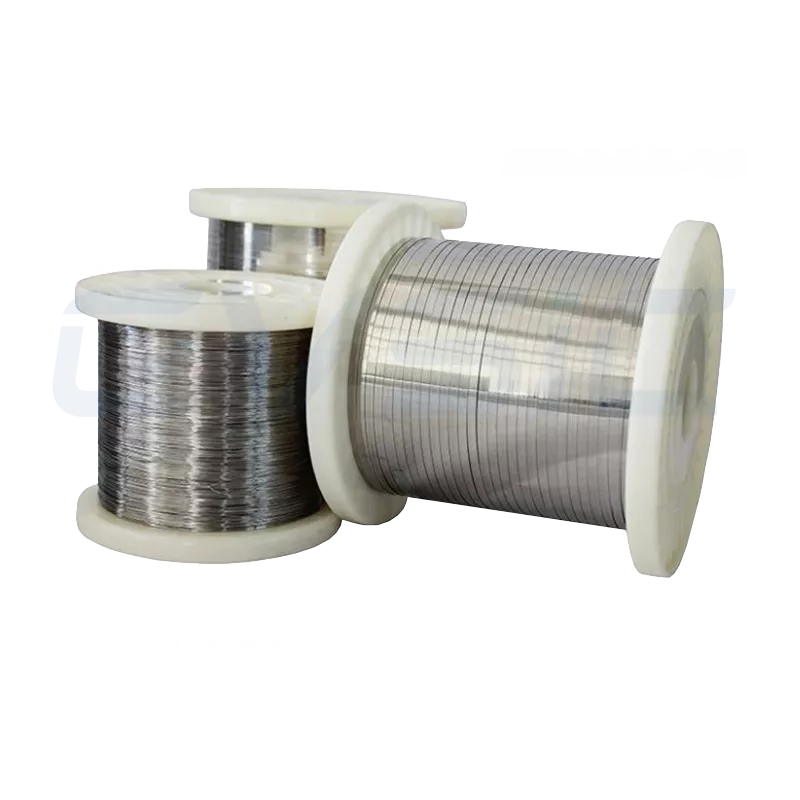

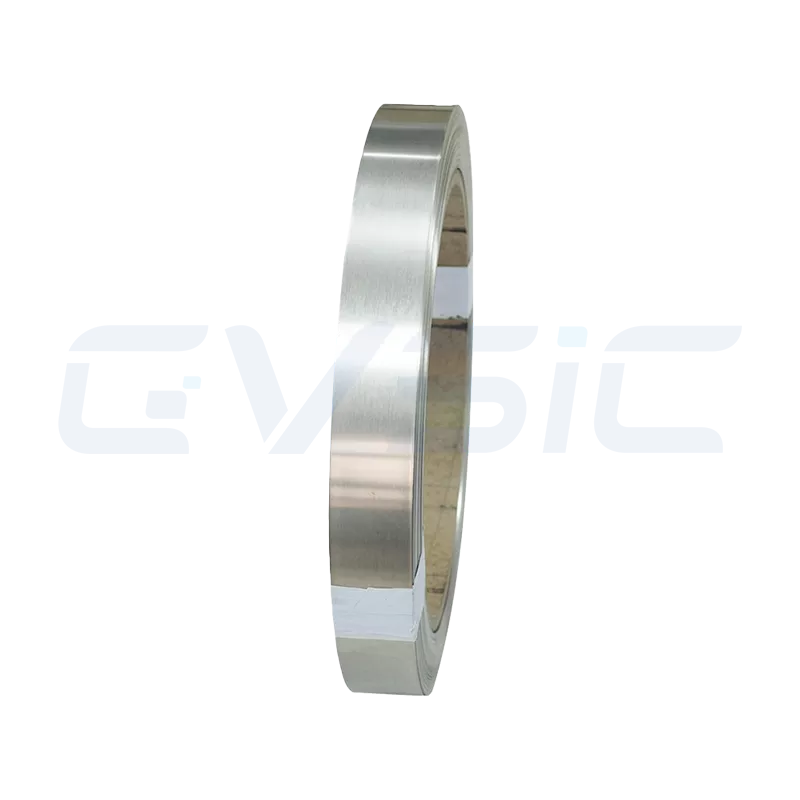

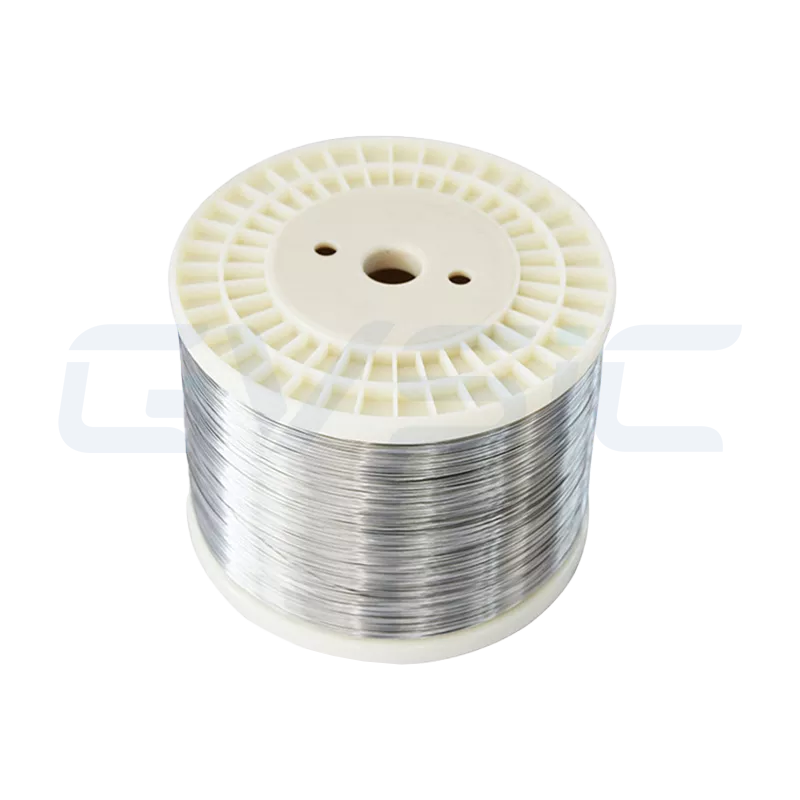

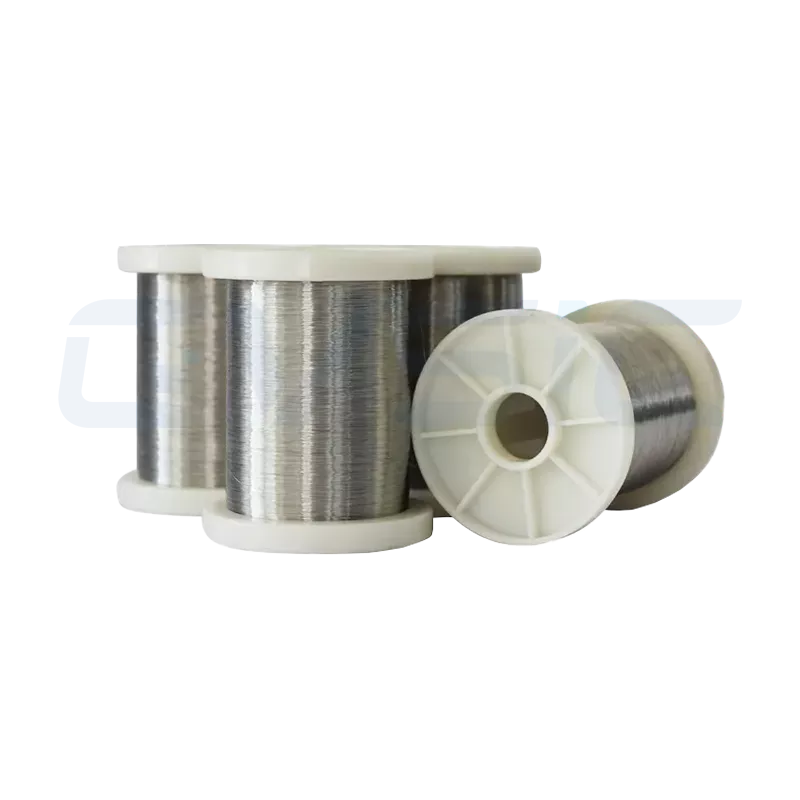

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Heaters, electric tubes, hair dryer wires, damping/cutting wires (foam/plastic)

Cr20Ni30 is a low-nickel, high-chromium NiCr resistance alloy wire designed for cost-controlled operation in mid-temperature industrial electric heating systems.

Typical mix is around 30% nickel (Ni) + 20% chrome (Cr), with straightforward engineering:

- Cuts nickel big time

- Pumps up chrome to cover for less stability at heat

In real jobs, Cr20Ni30 fits when costs are tight but fast oxidation from low-chrome NiCr is a no-go.

Key Features of Cr20Ni30

Cr20Ni30’s role is spot-on: Hold oxidation as strong as possible on a budget.

- Low nickel means so-so creep resistance and stability at high heat—not great for long-term full-blast runs.

- Around 20% chrome builds oxide film quicker in air—likes open or vented spots.

- Resistance stability is decent, not top-tier, but fine for mid-temps.

- It’s an “engineering trade-off” kind of pick, not chasing max performance.

You’ll see Cr20Ni30 more in mid-temp gear or budget big-volume stuff, not fancy long-life setups.

Cr20Ni30 (Equivalent to Ni70Cr30) Specs Table

| Item | Value |

|---|---|

| Alloy Name | Cr20Ni30 |

| Equivalent Systems | Nichrome 70/30, Ni70Cr30 |

| Common Aliases | Ni70Cr30 (global standard), Nichrome A |

| Composition (%) | Cr: 18–21%, Ni: 30–34%, Fe: Bal. |

| Max Temp | 1100°C |

| Resistivity (20°C) | 1.04 μΩ·m |

| Density | 7.9 g/cm³ |

| Thermal Conductivity | 43.8 KJ/m·h·°C |

| Expansion Coefficient | 19×10⁻⁶/°C |

| Melting Point | 1390°C |

| Elongation | >20% |

| Microstructure | Austenitic |

| Magnetic | Non-magnetic |

| Standout Traits | Solid stability, strong oxidation resistance—budget pick for mid-high temp electric heating |

| Common Uses | Heaters, electric tubes, hair dryer wires, damping/cutting wires (foam/plastic) |

| Available | Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat |

At the same temp, Cr20Ni30’s life usually runs into surface oxidation and hot spots, not big creep failures.

Typical Cr20Ni30 Spots: Budget-tight + mid-temp steady systems

Mid-temp industrial heating gear

- Running ≤1000°C

- Okay life needs, no extremes

Well-supported elements

- Spirals, waves, ceramic backs

- Covers for lower hot strength

Budget OEM gear

- Big volumes

- Can’t afford high-nickel

Upgrade from low-chrome NiCr

- Vs. Cr15Ni60

- Big oxidation life boost

Usage Tips & Limits

Long-term ≤950–1000°C: Go higher and resistance drift plus grain growth show up.

Skip frequent on-off or picky controls: Stability not enough for super strict power.

Best for mid-temp standard stuff: Not for premium OEM long-haul cores.

Cr20Ni30’s Place in NiCr Family

| Feature | Cr15Ni60 | Cr20Ni30 | Cr20Ni35 |

|---|---|---|---|

| Nickel | Medium | Low | Medium |

| Chrome | Low | High | High |

| Oxidation Fight | Solid | Strong | Strong |

| High-Temp Strength | Medium | Lower | Average |

| Temp Sweet Spot | Mid | Upper Mid | Mid-High |

| Continuous Life | Medium | Medium | Medium-Long |

| Cost | Medium | Lower | Medium |

When trimming nickel for savings but wanting better oxidation life, Cr20Ni30 is a smart mid-temp NiCr choice.

CVSIC Cr20Ni30 Custom Options

We got for Cr20Ni30 NiCr resistance wire:

- Diameters: Common mid-temp sizes

- Forms: Coils, straight, cut-to-length

- Extras: Coiling, shaping, pre-assembled parts

- Models: B2B wholesale, OEM, ODM

- Customers: Makers, element factories, engineering firms

Killer for price-watch projects and big buys.

Quality Control | Low-Nickel NiCr Keys

- Chrome levels and even surface control

- Defect management (cuts oxidation starters)

- Resistance consistency checks

- Mid-temp oxidation tests

Surface quality calls the shots on life for Cr20Ni30.

Cr20Ni30 NiCr resistance wire shines in:

- Slashing nickel costs

- Better oxidation than low-chrome NiCr

- Mid-temp controllable industrial heating

If you’re going for: Trim costs + slow oxidation + don’t push temps too high — Cr20Ni30 is a practical, no-nonsense NiCr choice.

FAQs | Engineering Stuff

Good for long-term high-heat runs?

Fine for mid-temp long runs—keep steady at 1000–1050°C or below.

Big diff from Cr20Ni35?

Lower nickel/cost, but trades some hot strength and life.

Swap for Cr15Ni60?

Yeah, better oxidation in mid-temp spots.

Fit continuous systems?

Good with controlled loads and solid supports.

Custom specs and steady supply?

You bet—built for B2B and OEM bulk.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Cr20Ni30 Alloy Heatin Wire

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

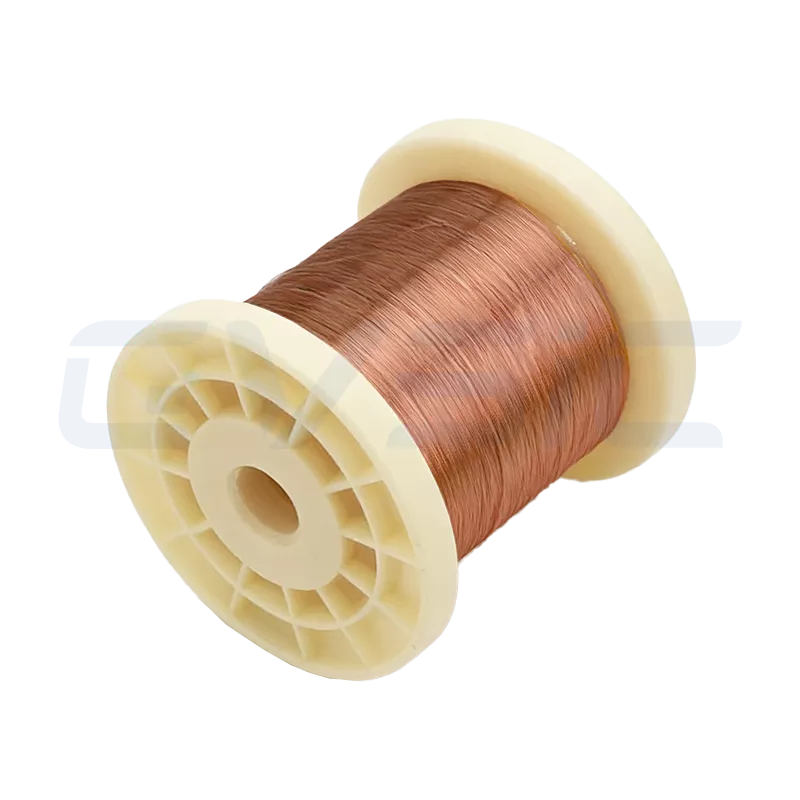

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support