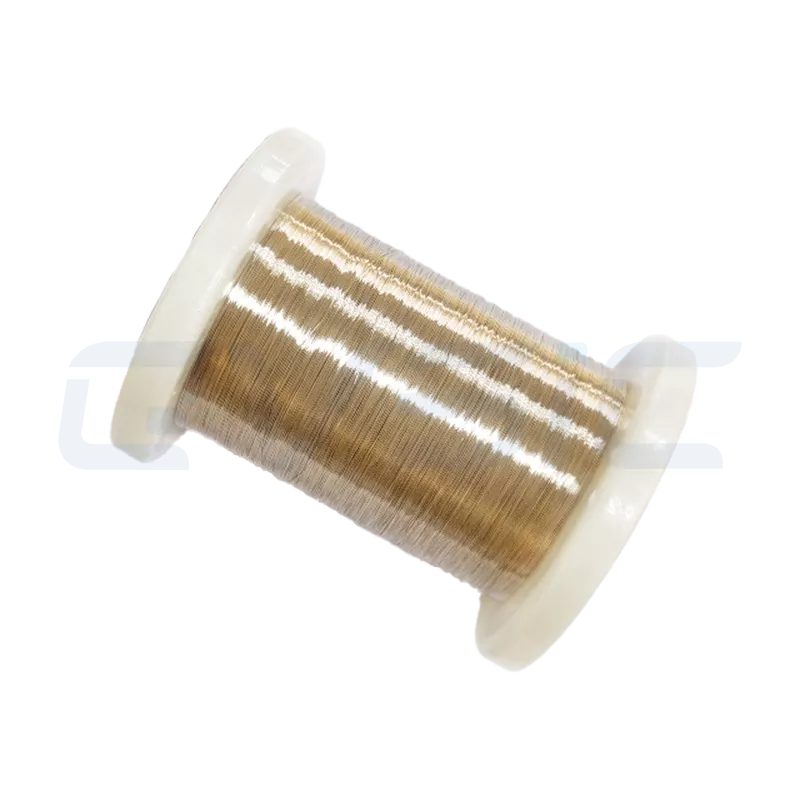

Cr20Ni35 Heating Wire

Cr20Ni35 is a medium-nickel high-chrome NiCr resistance wire that balances oxidation resistance and cost. Great for mid-to-high temp industrial electric heating systems. We support B2B custom, OEM, and bulk.

- Model: CV-Cr20Ni35

- Alloy Grade: Nichrome 35/20

- Main Composition:Ni: Cr: ≈20%, Ni: ≈35%, Fe: Bal.

- Max Temp: 1100–1150°C

- Resistivity (20°C): 1.02 μΩ·m

- Density: 8.0 g/cm³

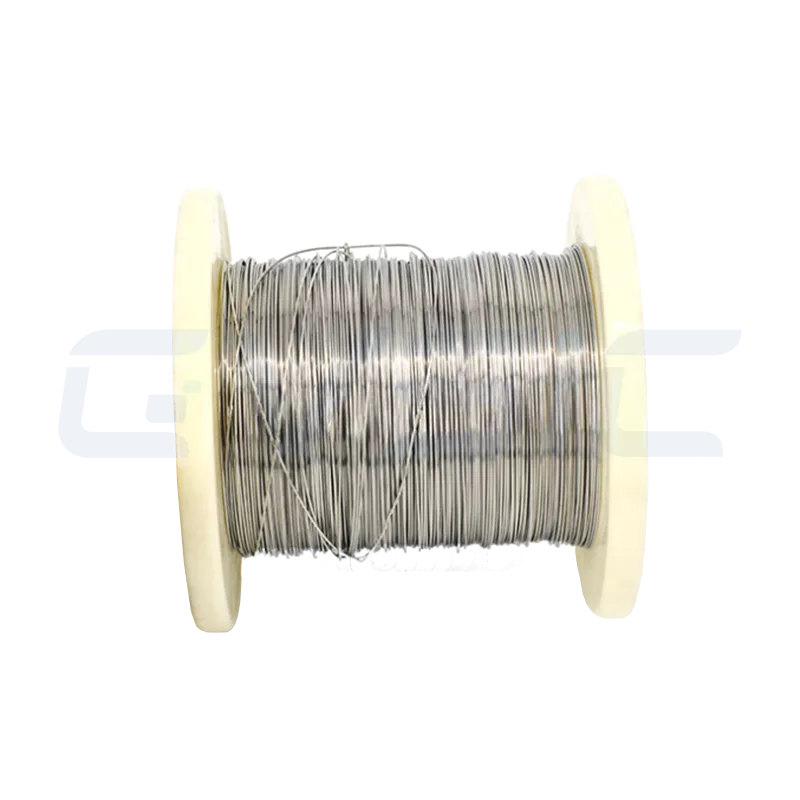

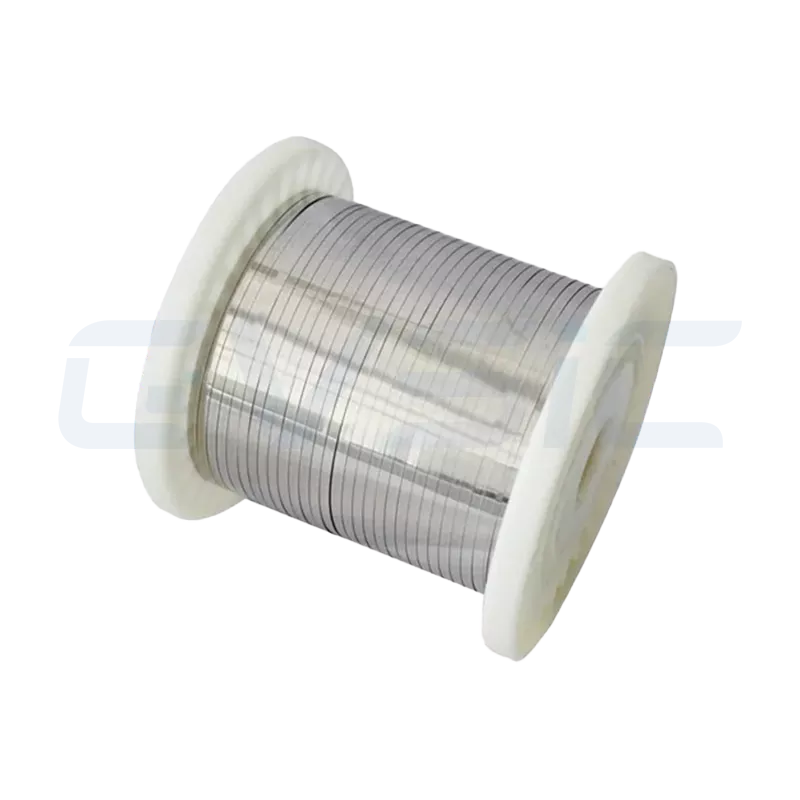

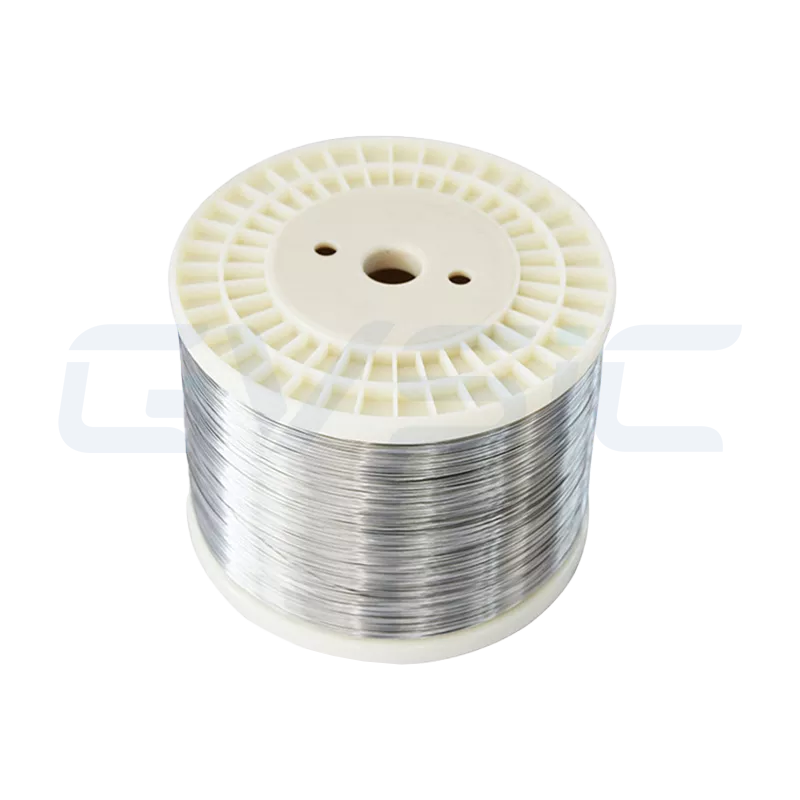

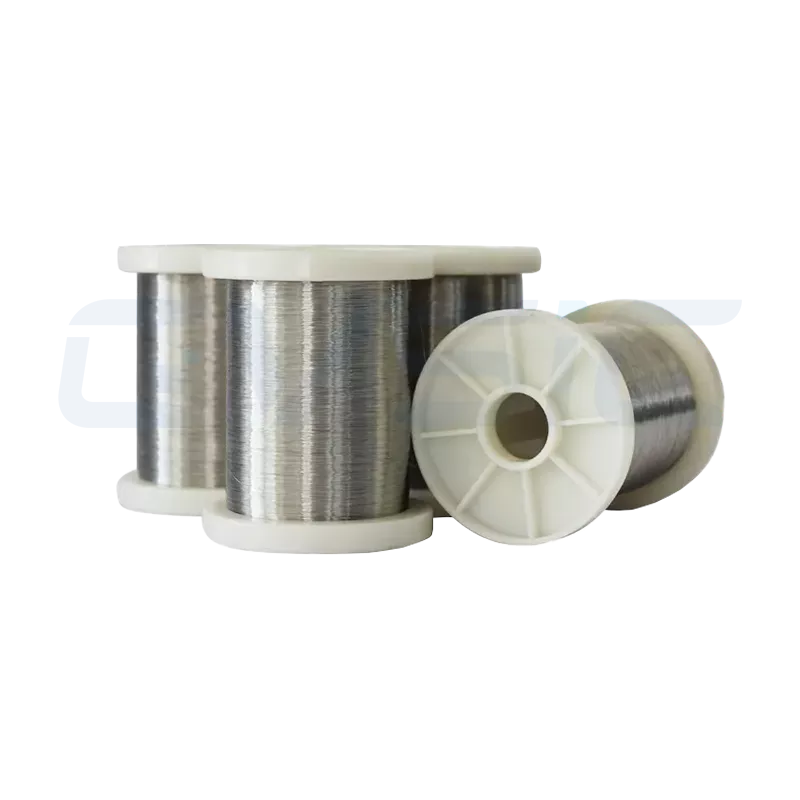

- Forms Available: Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat

- Common Uses: Mid-high temp industrial furnaces, ovens, heating tubes, durable elements

Cr20Ni35 is a medium-nickel, high-chromium NiCr resistance alloy wire designed for stable operation in mid-to-high temperature industrial electric heating systems.

Typical mix is around 35% nickel (Ni) + 20% chrome (Cr), with clear goals:

- Keeps nickel in check

- Cranks chrome to beef up oxidation resistance in air

In practice, Cr20Ni35 fits systems with a bit higher temps and longer runs, without jumping to high-nickel stuff.

Key Features of Cr20Ni35

Cr20Ni35 is like a “steady upgrade” from Cr20Ni30.

- A bit more nickel noticeably improves structure stability at heat.

- Vs. Cr20Ni30, resistance shifts are more controllable during hot-cold cycles.

- Around 20% chrome keeps oxidation resistance solid in air.

- Hits a nice sweet spot between cost and performance.

Cr20Ni35 extends life by better oxidation fight, not hotter strength.

It’s common in spots wanting “a step up from basic NiCr reliability, without high-nickel prices.”

Cr20Ni35 Specs Table

| Item | Value |

|---|---|

| Alloy Name | Cr20Ni35 |

| Equivalent Systems | Approximate Nichrome 35/20 |

| Composition (%) | Cr: ≈20%, Ni: ≈35%, Fe: Bal. |

| Max Temp | 1100–1150°C |

| Resistivity (20°C) | ≈1.02 μΩ·m |

| Density | ≈8.0 g/cm³ |

| Thermal Conductivity | ≈44 KJ/m·h·°C |

| Expansion Coefficient | ≈18×10⁻⁶/°C |

| Melting Point | ≈1400°C |

| Elongation | >20% |

| Microstructure | Austenitic |

| Magnetic | Non-magnetic |

| Standout Traits | Good stability, strong oxidation—balanced mid-high temp pick |

| Common Uses | Mid-high temp industrial furnaces, ovens, heating tubes, durable elements |

| Available | Diameters: 0.02–10mm; Strips: 0.02–2mm; Custom wire/strip/flat |

Cr20Ni35 life mostly comes down to oxidation rate, not creep or breaks.

Typical Cr20Ni35 Spots: “Oxidation first” mid-to-high temp systems

Mid-to-high temp industrial furnaces

- Needs decent oxidation life

- Lower loads/tension

Continuous runs with controlled loads

- Long heat times

- Chill surface loads

Budget mid-to-high temp OEM gear

- Skip high-nickel

- But Cr15Ni60 life too short

Standard element kits

- Mesh/spirals/waves

- Easy strength fixes structurally

Usage Tips & Limits

Long-term ≤1000–1050°C

- Still design loads carefully—don’t push like high-nickel.

Not for extreme life or super-hot systems.

Cr20Ni35 Selection Comparison

| Feature | Cr15Ni60 | Cr20Ni35 | Cr20Ni80 |

|---|---|---|---|

| Nickel | Medium | Lower | High |

| Chrome | Low | Higher | Medium |

| Oxidation Fight | Solid | Strong | Strong |

| High-Temp Strength | Medium | Average | Solid |

| Temp Spot | Mid | Mid-High | High |

| Continuous Life | Medium | Medium-Long | Long |

| Cost | Lower | Medium | Higher |

When oxidation life beats hot strength needs and nickel costs matter, Cr20Ni35 is a practical mid-high temp NiCr pick.

CVSIC Cr20Ni35 Custom Options

We offer for Cr20Ni35 NiCr resistance wire:

- Diameters: Common mid-high temp sizes

- Forms: Coils, straight, cut-to-length

- Extras: Coiling, shaping, pre-fab components

- Models: B2B wholesale, OEM, ODM

- Customers: Factories, engineers, element makers

Perfect for mid-high temp projects and repeat orders.

Quality Control | Oxidation Life Focus

- Chrome evenness control

- Surface management (cut oxidation starters)

- Resistance checks

- High-temp oxidation tests

Surface condition rules life for Cr20Ni35.

Cr20Ni35 NiCr resistance wire shines in:

- Better oxidation life than low-chrome NiCr

- Way lower cost than high-nickel

- Mid-high temp systems with structural strength fixes

If you’re aiming for: A tad higher temps + longer life + nickel costs down — Cr20Ni35 is a smart, practical NiCr pick.

FAQs

Long-term at 1150°C?

Nope—stick ≤1050°C long-term for steady oxidation life.

Big diff from Cr15Ni60?

Way stronger oxidation, but not much hotter strength boost.

Fit continuous runs?

Yeah with controlled loads—not high-load designs.

Replace some Cr20Ni80?

Sure when temp/strength needs lower—cheaper swap.

Custom and bulk?

You bet—great for B2B/OEM long-term.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Cr20Ni35 Heating Wire

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support