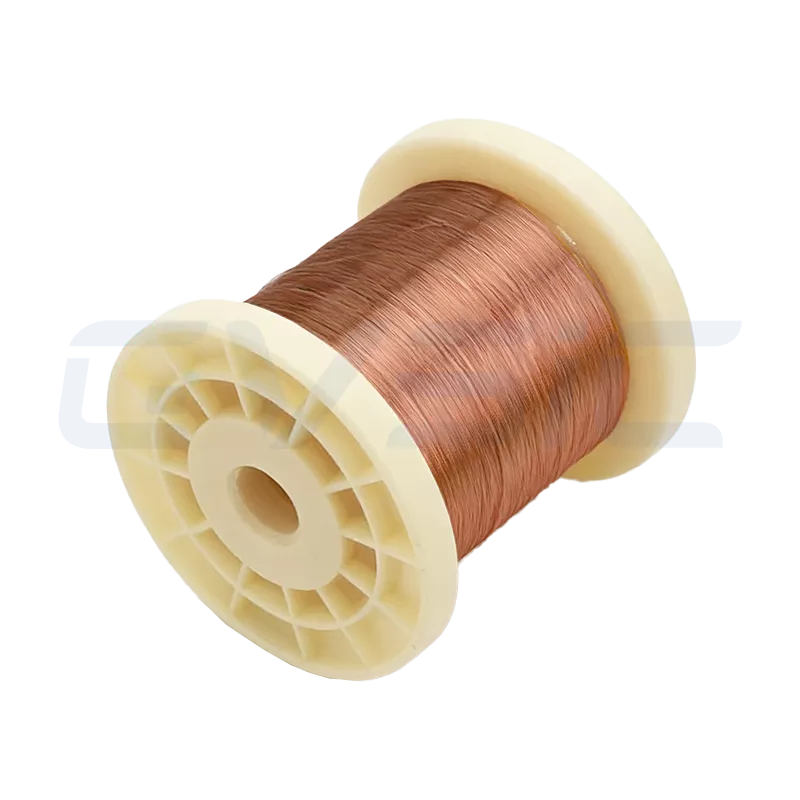

Cr30Ni70 Heating Wire

Cr30Ni70 is a high-nickel high-chrome NiCr resistance wire built for high-temp industrial electric heating systems, with top-notch oxidation resistance, high-temp strength, and long-term stability. We support B2B custom, OEM, and bulk.

- Model: CV-Cr30Ni70

- Alloy Grade: NiCr70/30

- Main Composition: Ni: Bal. (about 70%), Cr: 28–31%, Fe: ≤1.0%

- Max Temp: 1200°C

- Resistivity (20°C): 1.18 μΩ·m

- Density: 8.1 g/cm³

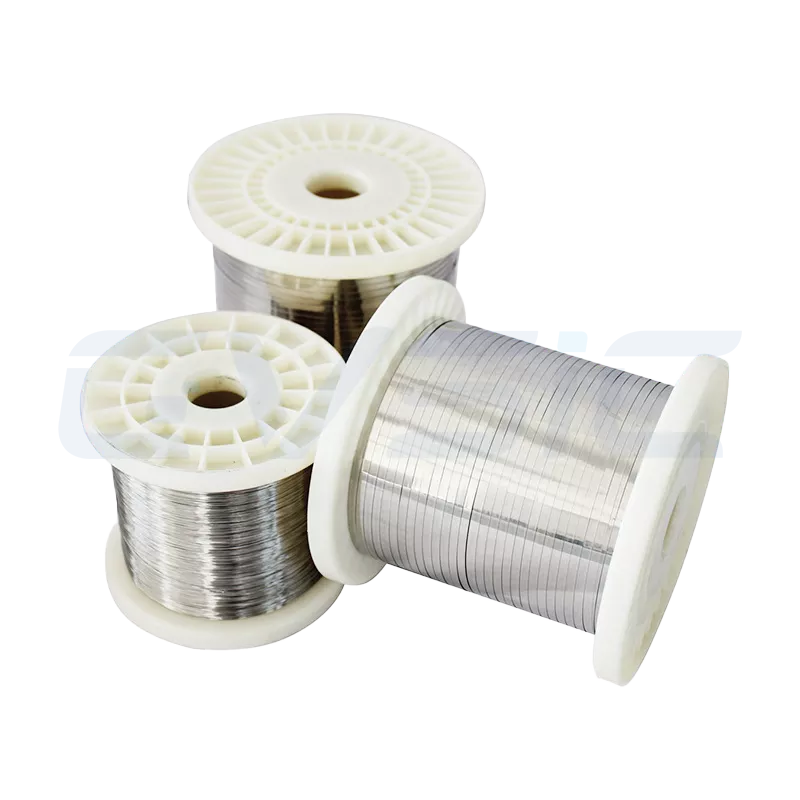

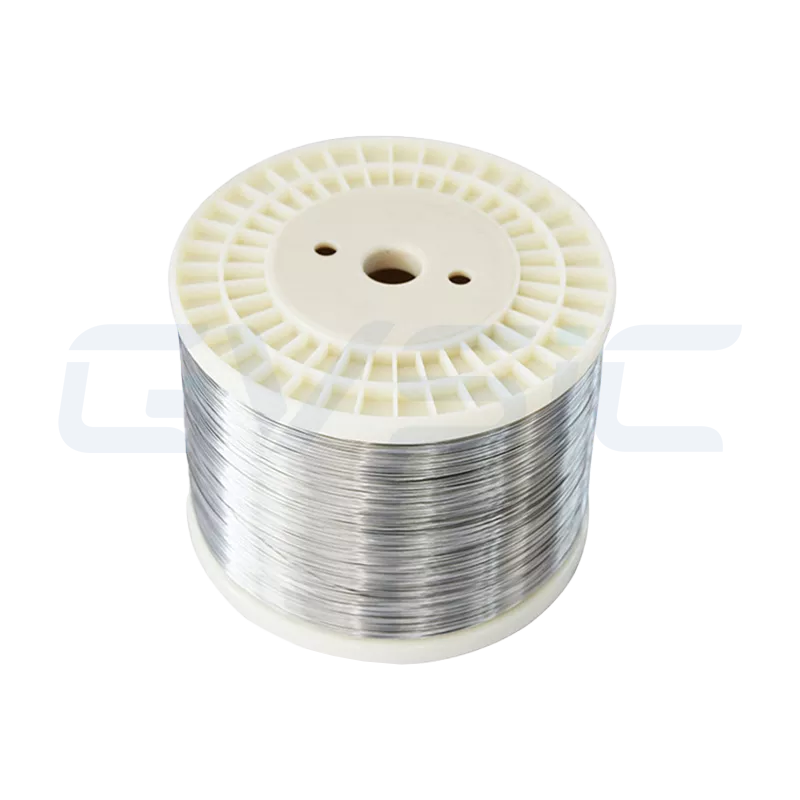

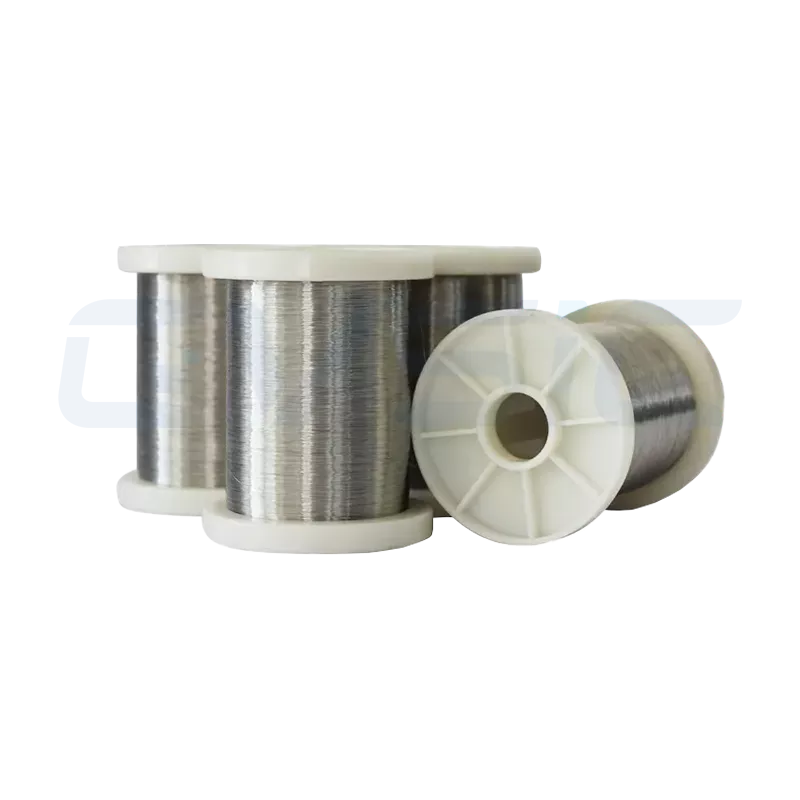

- Forms Available: Diameters: 0.02–10mm (round) Strips: 0.02–2mm Custom flat wire, rods, coils

- Common Uses: Industrial furnace wires – High-temp elements – Ceramic heaters – High-temp ovens/tunnel kilns – Mold heating, lab furnaces

Cr30Ni70 is a high-nickel, high-chromium NiCr resistance alloy wire designed for long-term stable operation in high-temperature industrial electric heating systems.

Typical mix is around 70% nickel (Ni) + 30% chrome (Cr), not chasing max temps, but targeting:

- Steady resistance over long runs

- Solid structure when hot

- Low creep and failure in non-stop ops

In real jobs, Cr30Ni70 fits “stability and life first” industrial electric heating, not budget-tight projects.

Key Features of Cr30Ni70

Cr30Ni70 is all about “stability and life first” in NiCr.

- Up to 30% chrome builds a super dense, stable oxide layer at high heat, slowing oxidation way down.

- 70% nickel keeps it tough and creep-resistant when hot.

- Rock steady structure and resistance in 1000–1200°C, big win for long hauls.

- Perfect for 24/7 non-stop, not chasing cheap.

Cr30Ni70 wins from “stable mix → stable structure → steady performance long-term.”

Cr30Ni70 (Ni70Cr30, High-Chrome Type) Specs Table

| Item | Value |

|---|---|

| Alloy Name | Cr30Ni70 |

| Equivalent System | Nichrome 70/30 (high-chrome type) |

| Common Aliases | Ni70Cr30, Nichrome 70/30, NiCr70/30 |

| Composition (%) | Ni: Bal. (about 70%), Cr: 28–31%, Fe: ≤1.0% |

| Max Temp | 1200°C (top in NiCr series) |

| Resistivity (20°C) | 1.18 μΩ·m |

| Density | 8.1 g/cm³ |

| Thermal Conductivity | 45.2 KJ/m·h·°C |

| Expansion Coefficient | 17×10⁻⁶/°C |

| Melting Point | 1380°C |

| Elongation | >20% |

| Microstructure | Austenitic |

| Magnetic | Non-magnetic |

| Standout Traits | Top oxidation fight – Great high-temp strength – Built for long continuous runs – Better heat stability/corrosion than 20Cr series |

| Common Uses | Industrial furnace wires – High-temp elements – Ceramic heaters – High-temp ovens/tunnel kilns – Mold heating, lab furnaces |

| Available | Diameters: 0.02–10mm (round) Strips: 0.02–2mm Custom flat wire, rods, coils |

| Processing | OEM/ODM, fixed resistance, cut-to-length, surface oxidation, vacuum annealing, etc. |

Cr30Ni70 shines in “time stability” at 1000–1200°C, not just peak temp.

Typical Cr30Ni70 Spots

High-temp industrial electric furnaces

- Heating wires, strips, meshes

- Needs even temps and reliable runs

Non-stop electric heating (24/7)

- Low resistance drift

- Low break risk

- Beats mid-nickel NiCr easy

Precision heat treat/temp control gear

- Cuts drift from aging

- Keeps params steady long-term

Premium OEM standard stuff

- Great for long bulk supply

- Engineering consistency

Usage Tips & Limits

Long-term ≤1150–1200°C

- Still watch loads—don’t just crank temp.

Pricey—not for super cheap projects.

Cr30Ni70 Selection Comparison

| Feature | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 |

|---|---|---|---|

| Nickel | High | Super High | Medium |

| Chrome | Medium | High | Low |

| Oxidation Fight | Strong | Top-Notch | Solid |

| High-Temp Strength | Solid | Rock-Solid | Average |

| Resistance Stability | High | Top-Notch | Medium |

| Continuous Life | Long | Longer | Medium |

| Cost | Higher | Highest | Medium |

NiCr picks are about managing risks, not just temp numbers.

When aiming for long stable runs, low maintenance, high consistency over lowest cost, Cr30Ni70 is the top NiCr choice.

CVSIC Custom Options

We offer engineering-grade for Cr30Ni70 NiCr resistance wire:

- Diameters: Common industrial (custom too)

- Forms: Coils, straight, cut-to-length

- Extras: Coiling, shaping, pre-fab components

- Models: Wholesale, OEM, ODM

- Customers: Makers, engineering firms, system integrators

Perfect for premium long-term kits and project buys.

Quality Control | Batch Consistency Wins

- Steady NiCr melt/composition control

- Double checks resistivity/diameter

- High-temp aging/oxidation tests

- Traceable batches for repeat projects

We care about “qualified” plus consistent engineering performance across batches.

Cr30Ni70 NiCr resistance wire isn’t cheap—it’s made for high-temp, long-term, stable industrial electric heating.

If you’re after: Less maintenance · Longer life · Steadier heating — Cr30Ni70 is worth putting first.

FAQs

Long-term at 1200°C?

In air, keep ≤1150–1200°C long-term with smart loads for best life.

Main edge over Cr20Ni80?

Better high-temp strength, creep fight, long-term resistance stability—killer for continuous systems.

Good for frequent on-off?

Yeah—high-nickel austenitic handles cycles better.

Totally—great for OEMs watching life, consistency, maintenance costs.

Custom and steady supply?

You bet—tailored specs/stable bulk for projects.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Cr30Ni70 Heating Wire

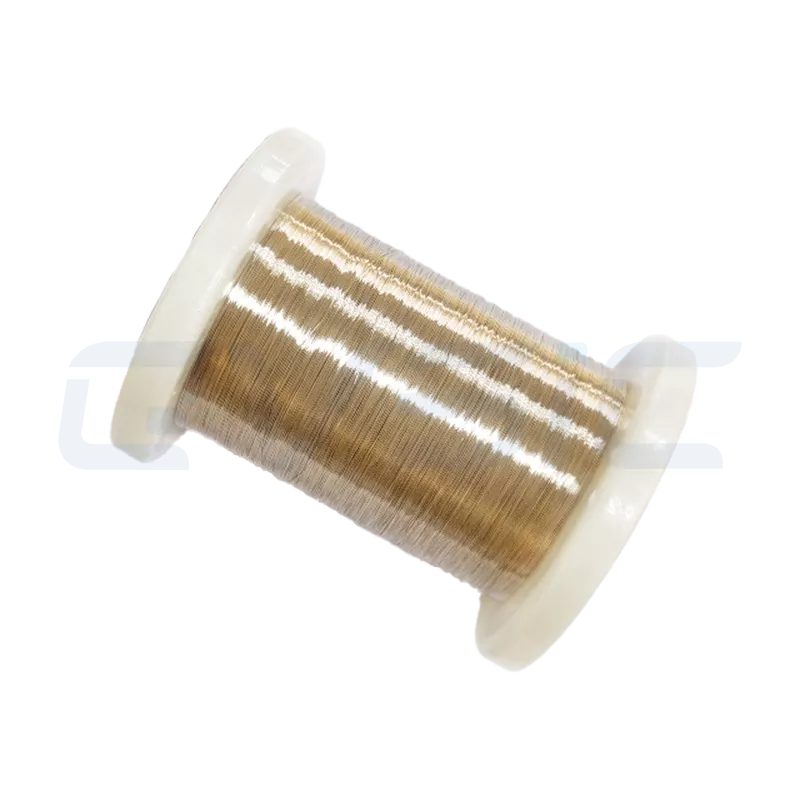

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

CuNi2

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support