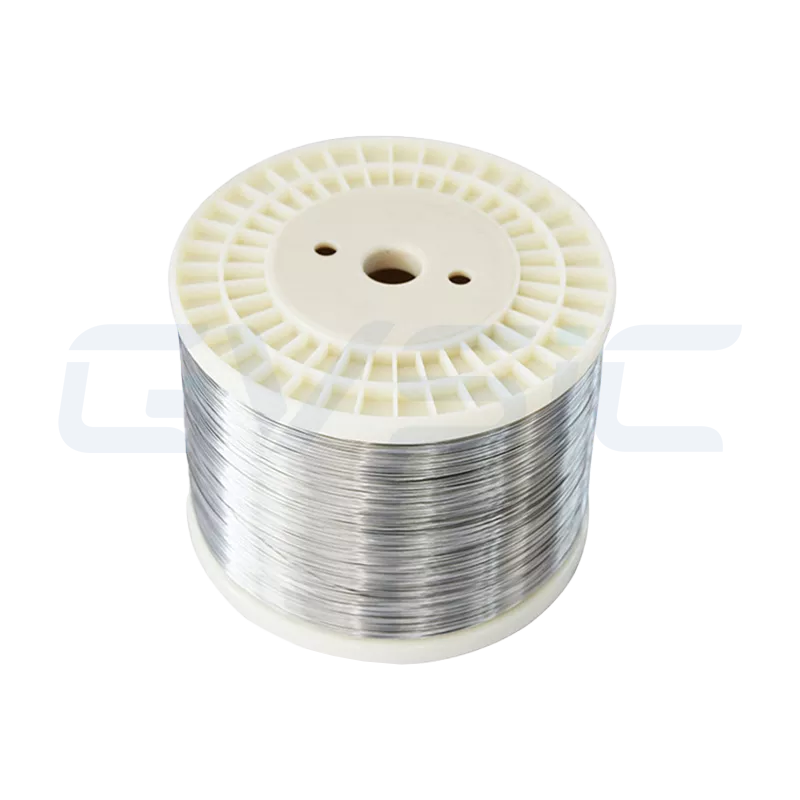

CuNi2

CuNi2 low-nickel high-copper NiCu alloy wire brings moderate resistivity, solid oxidation resistance, long-term temp stability, and low magnetism—spot-on for industrial electric heating systems, ovens, and precision heat treat gear.

- Model: CV-CuNi2

- Alloy Grade: CuNi2 (NC005)

- Main Composition: Ni ≈2, Cu Bal

- Max Temp: 250°C

- Resistivity (20°C): 0.05 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip

- Best Atmosphere: Air / Mildly oxidizing

CuNi2 is a NiCu alloy wire built for stable industrial electric heating jobs like ovens, heat treat equipment, and non-stop furnaces.

- High copper, low nickel mix → Moderate resistivity → Awesome for low-power long-haul heating

- Killer oxidation resistance → Steady surface → Longer wire life

- Low magnetism → Better heat evenness → Precise heat treat control

Standout Features of CuNi2

CuNi2 is the lowest-nickel in NiCu—basically a “copper-heavy” alloy.

- Around 2% nickel—resistivity not crazy high, but way steadier than pure copper.

- Top-notch heat conduction—heats evenly, no hot spots, easy.

- Resistance shifts linearly with temp—control logic straightforward.

Fits great for:

- Low or medium-low temp heating

- Can’t crank power density too high

- In non-stop systems with moderate temps, it’s super tough

CuNi2 (NC005) Specs Table

| Item | Value |

|---|---|

| Alloy Name | CuNi2 (NC005) |

| Composition (%) | Ni ≈2, Cu Bal. |

| Max Continuous Temp | 250°C |

| Melting Point (approx.) | 1090°C |

| Density | 8.9 g/cm³ |

| Resistivity (20°C) | 0.05 μΩ·m ±10% |

| Tensile Strength | ≥220 MPa |

| Elongation (Φ>1.0) | ≥25% |

| TCR (20–600°C) | <120×10⁻⁶/°C |

| Standout Traits | Super low resistance, weldable, strong mechanically |

| Common Uses | Low-res resistors, shunts, motor windings, auto low-res parts |

| Available | Diameters 0.02–10mm; Strips 0.02–2mm; Custom wire/strip |

Typical CuNi2 Spots

- Industrial furnaces/ovens: Low-power wires for even temp control

- Non-stop heating systems: Copper-base NiCu stable oxidation for long life

- Heat treat gear: Steady resistance/uniform heat in precision jobs

- Premium OEM fits: Custom coils/pre-fab parts for full integration

Usage Tips & Limits

Long-term ≤200–250°C

- Not for tiny size/high-power designs

- More “industrial workhorse” than performance beast

CuNi2 Selection Comparison

| Grade | Ni% | Cu% | Resistivity (Ω·mm²/m) | Oxidation | High-Temp Strength | Life | Cost | Quick Take |

|---|---|---|---|---|---|---|---|---|

| CuNi2 | 2 | 98 | 0.435–0.45 | Solid | Medium | Medium-Long | Low–Medium | Copper-heavy low-nickel → Steady medium power long-term, bulk low-temp winner |

| CuNi6 | 6 | 94 | 0.45–0.48 | Better | Medium | Medium-Long | Medium | Bit more Ni → Higher temp okay, cost up |

| CuNi10 | 10 | 90 | 0.48–0.52 | Solid | Medium | Medium | Medium | More Ni → Handles hotter, price bump |

| NiCr20 | 80 | 20 | 1.0–1.1 | Excellent | High | Long | High | High-nickel NiCr → Hot apps, but low-power pricey |

CVSIC CuNi2 Custom Options

- Diameters: 0.05–2 mm, custom

- Forms: Coils, straight, cut-to-length

- Extras: Coil winding, shaping, pre-fab components

- Models: Wholesale, OEM, ODM

- Customers: Industrial makers, heat treat firms, system integrators

- Tip: Great for long bulk buys—steady wire/dimensions

Quality & Consistency

- Tight Ni/Cu ratio control for resistance/oxidation

- 100% batch resistivity/size checks for engineering match

- Simulated long-run aging/oxidation—drift < ±3%

- Traceable spools for bulk project control

FAQs

Max long-term temp for CuNi2?

Air long-term 200–250°C, short bursts 300°C. Copper-base NiCu solid oxidation, steady resistance long-haul.

CuNi2 or CuNi6 for non-stop ovens?

CuNi2 → Medium power low-temp steady, cheap; CuNi6 → Hotter okay, costlier—pick CuNi2 for continuous medium-low ovens.

Thermal cycles hit CuNi2?

Copper low-nickel handles tons in 300–350°C—steady structure, low drift, tough integrity.

OEM custom CuNi2 parts—what processing?

Coil winding, shaping, pre-fab—drop right into furnaces/heat treat gear.

Big volume CuNi2 for long projects?

Batch trace, composition/resistance checks—perfect long-term bulk, consistent performance.

High magnetic fields?

Super low magnetism—fine for precision heat treat, no temp control interference.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To CuNi2

CuNi44 Alloy Wire

- Model: CV-CuNi44

- Alloy Grade: CuNi44 (NC050)

- Main Composition: Ni ≈44, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.50 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Precision resistors, strain gauges, bridges, instrument standards

CuNi34 Alloy Wire

- Model: CV-CuNi34

- Alloy Grade: CuNi34 (NC040)

- Main Composition: Ni ≈34, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.40 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, ultra-thin foil

- Common Uses: Standard resistors, precision measure, lab instruments

CuNi30 Alloy

- Model: CV-CuNi30

- Alloy Grade: CuNi30 (NC035)

- Main Composition: Ni ≈30, Mn: 1%, Cu Bal.

- Max Temp: 500°C

- Resistivity (20°C): 0.35 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi23 Alloy

- Model: CV-CuNi23

- Alloy Grade: CuNi23 (NC030)

- Main Composition: Ni ≈23, Mn: 0.5%, Cu Bal.

- Max Temp: 450°C

- Resistivity (20°C): 0.30 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Fine wire, strip, bundled; Custom coils

- Common Uses: Precision resistors, measuring gear, industrial controls

CuNi19 Alloy Wire

- Model: CV-CuNi19

- Alloy Grade: CuNi19 (NC025)

- Main Composition: Ni ≈19, Mn: 0.5%, Cu Bal.

- Max Temp: 400°C

- Resistivity (20°C): 0.25 μΩ·m ±5%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil

- Common Uses: Precision resistors, measuring gear, heating elements

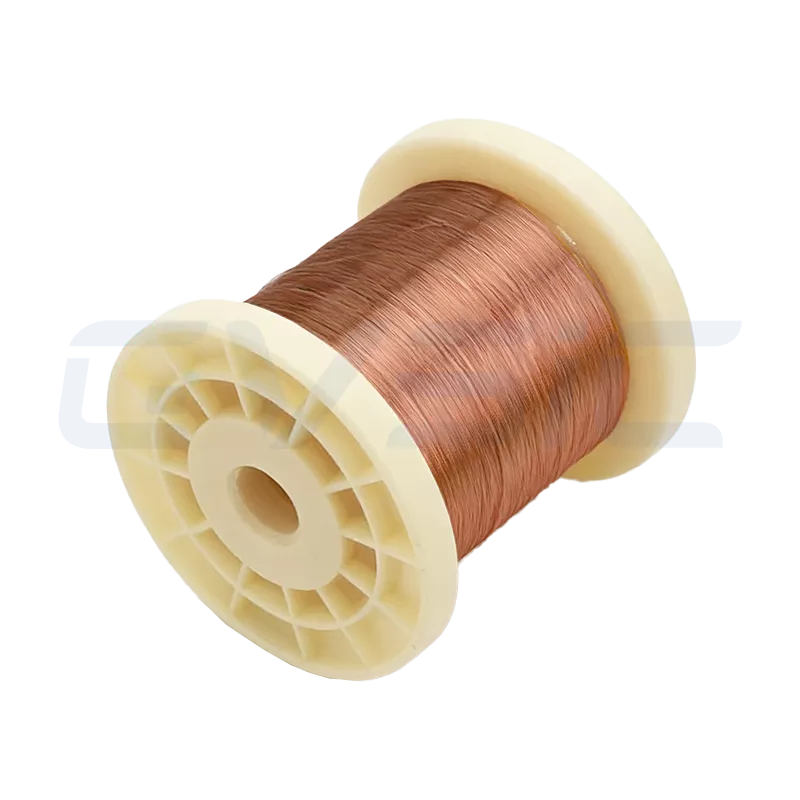

CuNi10 Alloy Wire

- Model: CV-CuNi10

- Alloy Grade: CuNi10 (NC015)

- Main Composition: Ni ≈10, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.15 μΩ·m ±10%

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, flat; OEM coils

- Common Uses: Instrument resistors, heating strips, sensor parts

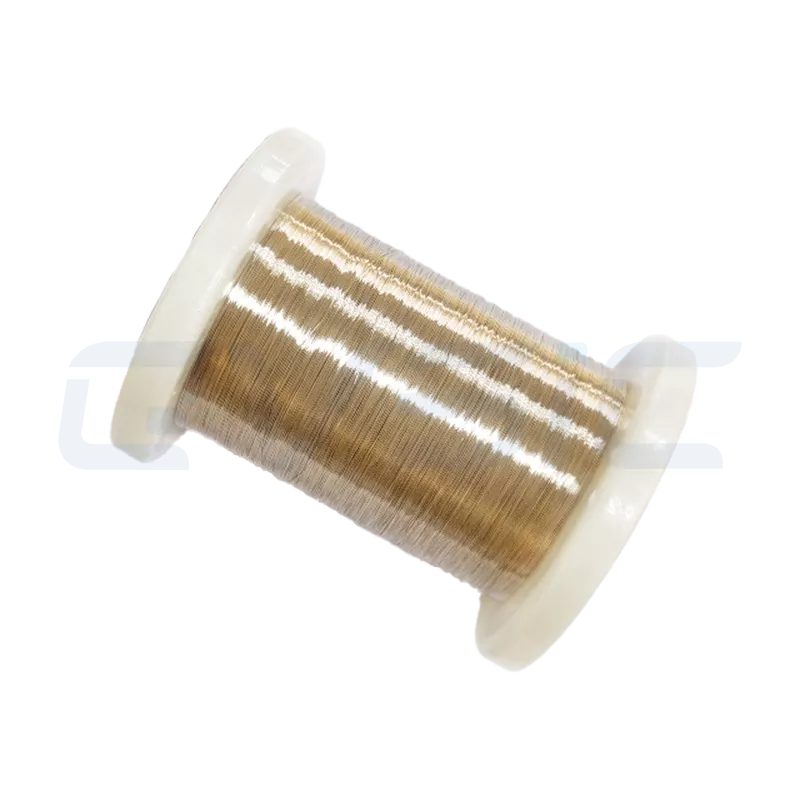

CuNi6 Alloy Wire

- Model: CV-CuNi6

- Alloy Grade: CuNi6 (NC010)

- Main Composition: Ni ≈6, Cu Bal.

- Max Temp: 350°C

- Resistivity (20°C): 0.10 μΩ·m

- Density: 8.9 g/cm³

- Forms Available: Wire, strip, foil; Hard/soft options

- Common Uses: Low-res parts, shunts, motor coils, electrical links

Cr20Ni80 Heating Wire

- Model: CV-Cr20Ni80

- Alloy Grade: Ni80Cr20

- Main Composition: Ni: Bal., Cr: 20–23, Fe: ≤1%

- Max Temp: 1200°C

- Resistivity (20°C): 1.09 μΩ·m

- Density: 8.4 g/cm³

- Forms Available: Diameters: 0.018–10mm; Strips: 0.02–2mm; Custom tolerances

- Common Uses: High-temp furnaces, lab gear, ceramic sintering, cutting wires, appliance heaters

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support