Comprehensive Guide to Tube Furnaces: Types, Principles, and Applications

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

The Sliding Tube Furnace, a globally applicable solution, supports 1200°C high-temperature sintering and rapid cooling. It has an alumina fiber furnace chamber and 30-segment intelligent temperature control, making it suitable for lithium battery materials, ceramics, and atmosphere reduction. This furnace supports low vacuum and inert atmospheres (N₂, CO₂, Ar), meeting the diverse needs of global research and production. Contact us now to learn more about its worldwide applications!

The Sliding Tube Furnace, an innovative device tailored for high-temperature heat treatment and rapid cooling, stands out with its unique features. It boasts a high-purity alumina polycrystalline fiber furnace chamber, domestically produced high-quality resistance wire (with an option for Swedish Kanthal A1 imported resistance wire), and a maximum temperature of 1200°C. This furnace supports low vacuum, positive pressure, and inert atmospheres (N₂, CO₂, Ar), making it a versatile solution for various industries and research experiments.

This furnace model adopts a double-layer shell structure and a 30-segment programmable intelligent control system, combined with phase-shift triggering and thyristor control, achieving temperature control accuracy of ±1°C, uniform temperature distribution, fast heating/cooling rates, and energy efficiency. Suitable for laboratory research and small-scale production in universities, research institutes, and industrial enterprises, particularly for high-temperature atmosphere sintering, atmosphere reduction, chemical vapour deposition (CVD), and vacuum annealing processes.

The Sliding Tube Furnace is widely used in the following industries and processes:

This furnace type provides an ideal solution for customers requiring rapid cooling, precise atmosphere control, and high-efficiency thermal processing, particularly suitable for laboratory research and small-scale production.

The Sliding Tube Furnace, featuring advanced technology and user-centric design, offers the following core advantages:

CVSIC offers comprehensive customisation services to ensure seamless integration with your production and R&D requirements:

Contact CVSIC for a customised sliding rapid cooling tube furnace solution tailored to your industry, supporting global wholesale and custom orders.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

What is a Tube Furnace? Your Gateway to High-Temperature Applications Tube furnaces are essential high-temperature heating systems widely…

Rotary vs. Fixed Tube Furnaces: Choosing the Ideal Solution for Your Process When processing powder materials, issues like…

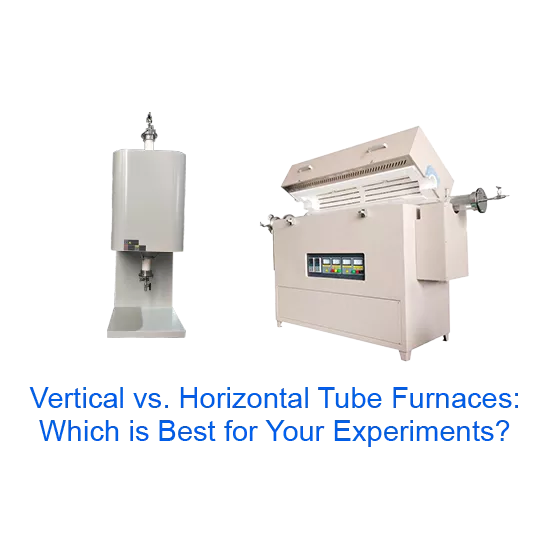

Vertical vs. Horizontal Tube Furnaces: Choosing the Right Equipment for Your Needs When selecting tube furnaces for materials…

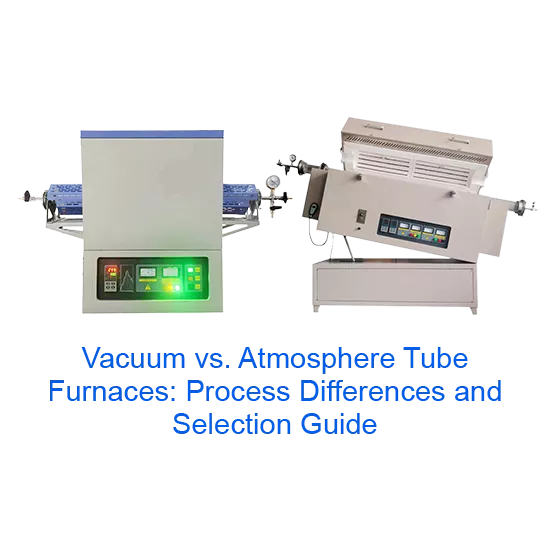

Vacuum vs. Atmosphere Tube Furnaces: Selecting the Optimal Equipment for Your Experiments Sample oxidation or contamination in high-temperature…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support