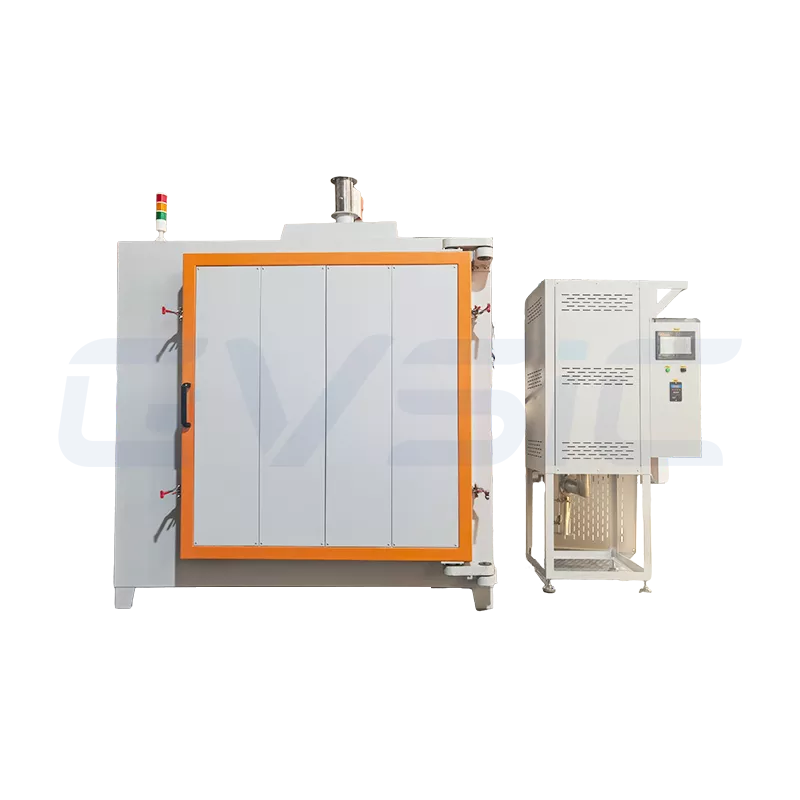

Debinding and Pre-Sintering Integrated Furnace

650℃/1200℃ Debinding and Pre-Sintering Integrated Furnace

The CVSIC Debinding and Pre-Sintering Furnace is designed for ceramic materials such as alumina and zirconia, integrating degreasing and pre-sintering functions. It supports temperatures ranging from 650°C to 1200°C and is equipped with VOC exhaust gas cracking and rapid cooling technology. Ideal for 3D printing and the electronics industry, it offers customized solutions and global wholesale services.

- Name: Debinding and Pre-Sintering Integrated Furnace

- Furnace Chamber: Ceramic Fiber

- Heating Elements: Resistance Wire, SiC Heating Elements

- Maximum Temperature: 650°C, 1200°C

- Voltage: 380V

- Vacuum System: None

- Available Atmosphere: Inert atmosphere (N₂, CO₂, Ar₂, etc.)

- Process Applications: Sintering, Brazing, Debinding Sintering, Heat Treatment, Annealing

The CVSIC Debinding and Pre-Sintering Integrated Furnace is a high-performance ceramic material processing device that integrates debinding and pre-sintering functions. It is widely applicable for the thermal processing requirements of 3D-printed aluminium oxide, zirconium oxide, magnesium oxide, and other ceramic materials. The furnace features a ceramic fiber furnace chamber equipped with resistance wire and silicon carbide rod heating elements, capable of reaching a maximum temperature of 1200°C . It supports inert atmosphere environments (N₂, CO₂, Ar), ensuring process flexibility and high-quality material processing.

This furnace innovatively combines low-temperature (≤650°C) hot air circulation heating and high-temperature (650°C-1100°C) five-sided thermal radiation heating technology to ensure uniform temperature distribution, meeting the diverse requirements of ceramic material processing. It has a porous ceramic preheating air intake system, adjustable airflow parameters, VOC exhaust gas cracking equipment, and rapid cooling functionality, optimizing production efficiency while achieving environmentally friendly emissions.

CVSIC Debinding and Presintering Furnace Advantages

The CVSIC Debinding and Pre-Sintering Furnace, featuring advanced technology and user-centric design, offers the following core advantages:

- Multi-functional integrated design: Seamlessly integrates degreasing and pre-sintering functions, supporting low-temperature (≤650°C) hot air circulation and high-temperature (650°C-1100°C) five-sided thermal radiation heating to meet diverse process requirements.

- Excellent temperature uniformity: Combining five-sided resistance wire/silicon carbide rod heating with a porous ceramic preheating air intake system ensures uniform temperature distribution inside the furnace, enhancing material processing quality.

- Efficient air intake system: Utilising porous ceramic preheating technology and ceramic air duct design, the airflow is uniformly adjustable, effectively removing oily gases and optimising degreasing performance.

- Environmental protection VOC treatment: Equipped with a 900°C VOC exhaust gas cracking system, achieving complete cracking of exhaust gases and meeting strict environmental standards.

- Flexible airflow control: Adjustable airflow parameters to accommodate different degreasing volume requirements and meet various process scenarios.

- Rapid cooling technology: Adjustable cooling rates to protect products from thermal stress risks caused by rapid temperature drops.

- High-durability furnace chamber: The ceramic fiber furnace chamber is heat-resistant and corrosion-resistant, extending the equipment’s service life.

Debinding and Presintering Furnace Application

- 3D-printed ceramics: Suitable for degreasing and pre-sintering processes of ceramic materials such as alumina, zirconia, and magnesia.

- Electronics industry: Supports heat treatment and sintering of electronic ceramic components.

- Advanced materials research and development: Used for developing and testing high-performance ceramics and composite materials.

- Brazing: Provides a uniform temperature field, suitable for precision brazing processes.

- Heat treatment and annealing: Meets metal and ceramic materials’ annealing and heat treatment requirements.

- Degreasing and sintering: Efficiently removes organic binders from ceramic or metal injection molding.

This furnace type provides an ideal solution for manufacturers and R&D institutions requiring efficient, environmentally friendly, and multifunctional heat treatment equipment.

CVSIC Customization Services

CVSIC offers comprehensive customization services to ensure the equipment perfectly aligns with your production needs:

Furnace chamber dimensions: Customize heating zone dimensions and volume based on production scale.

- Temperature Configuration: Customizable temperature ranges from 650°C to 1200°C to meet specific process requirements.

- Atmosphere System: Customizable inert gas (N2, CO2, Ar) or other atmosphere environments.

- Air Inlet and Exhaust Gas Treatment: Customizable porous ceramic air inlet systems or high-temperature exhaust gas decomposition equipment based on exhaust gas characteristics.

- Control System: Customized PLC and touchscreen interface for optimized automation and data monitoring.

Optional Accessories

- Mullite Multi-Layer Furnace Rack: Enhances furnace space utilization and increases processing capacity.

- High-Temperature Exhaust Decomposition Package: Provides an enhanced high-temperature decomposition solution for highly irritating exhaust gases.

- Global Support: Offer installation guidance, operational training, and maintenance services to ensure the stable, long-term operation of the equipment.

Contact CVSIC to obtain customized Debinding and Pre-Sintering Furnace solutions tailored to your industry, supporting global wholesale and custom orders.

Looking for Reliable High Temperature Heating Solutions?

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

Products Related To Debinding and Pre-Sintering Integrated Furnace

Hot Air Circulation Debinding Furnace

- Name: Hot Air Circulation Debinding Furnace

- Furnace Chamber: Stainless Steel Chamber

- Heating Element: Resistance Wire

- Maximum Temperature: 650°C

- Operating Temperature: 600°C

- Vacuum Level: Non-Vacuum

- Available Atmosphere: Inert Atmosphere (N₂, CO₂, Ar₂, etc.)

- Application Processes: Sintering, Debinding Sintering, Heat Treatment

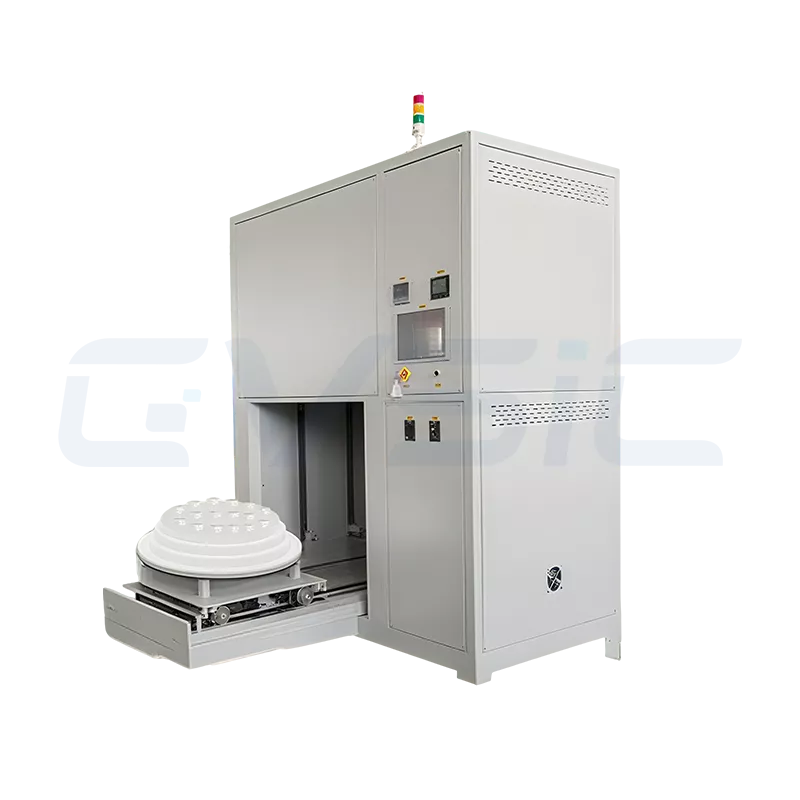

Lifting Atmosphere Sintering Furnace

- Name: Atmosphere debinding and sintering furnace

- Furnace chamber: Ceramic fiber

- Heating elements: MoSi2 heating elements

- Maximum temperature: 1700°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Available Atmosphere: Inert Gas (N₂, CO₂, Ar₂)

- Applications: Degreasing Sintering, Heat Treatment

Bottom Loading Debinding and Sintering Furnace

- Name: Degreasing and Sintering Furnace

- Furnace Lining: Ceramic Fiber

- Heating Elements: MoSi2 Heating Elements

- Maximum Temperature: 1750°C

- Voltage: 110V or 220V, 50Hz/60Hz

- Heating Rate: 0-15°C/min

- Process Applications: Degreasing Sintering, Heat Treatment

- Brand: CVSIC

Hydrogen Furnace

- Name: Hydrogen Sintering Furnace

- Furnace Chamber: Ceramic Fiber Furnace Chamber

- Temperature: With maximum working temperature 1600℃

- Heater: SiC Element, MoSi₂ Element, Resistance Wire

- Dimensions: Customizable furnace chamber dimensions

- Vacuum and Atmosphere System: Customizable low vacuum or inert gas (N₂, CO₂, Ar)

- Application Processes: Sintering, Brazing, Heat Treatment, Annealing, Powder Metallurgy

- MOQ: 1

- Services: OEM, ODM, Private Label

- Country of Origin: China

China One-Stop Customized Industrial Heating Solutions

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support