Dental Furnaces: A Comprehensive Guide from Sintering Furnaces to Porcelain Furnaces

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

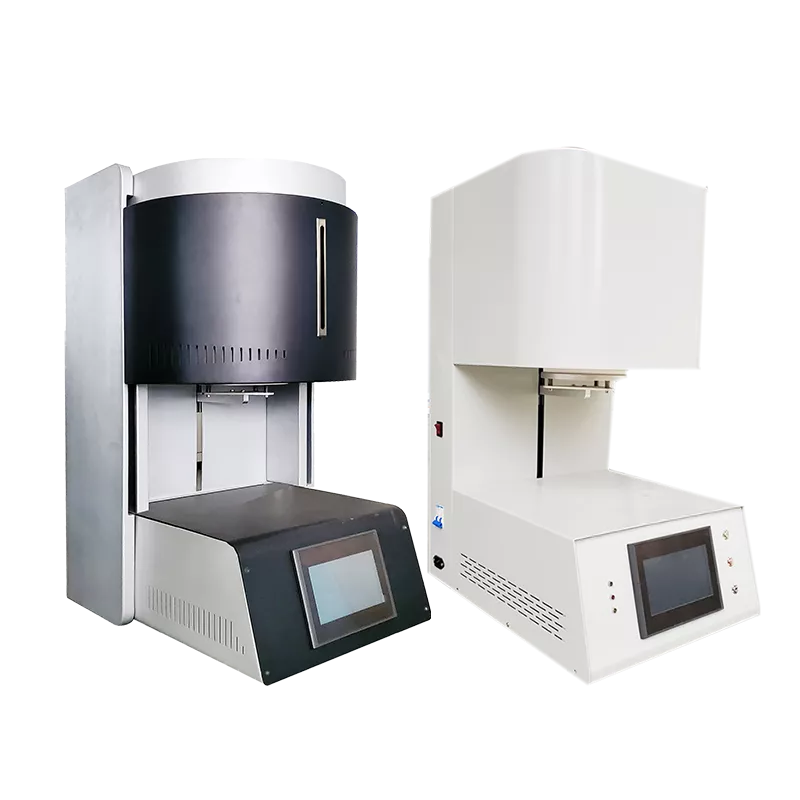

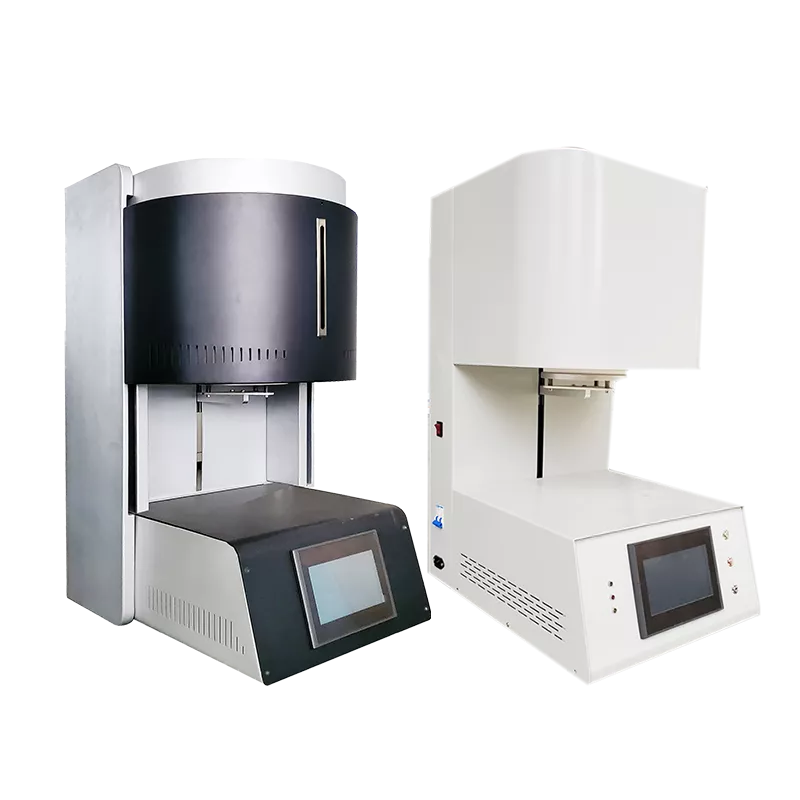

The CVSIC Porcelain Kiln delivers uniform heating and precise porcelain casting with a maximum temperature of 1200 °C, ±1°C control accuracy, and 100 built-in programs. Compact, energy-saving (1.6kW), and user-friendly, it is ideal for dental laboratories and manufacturers worldwide.

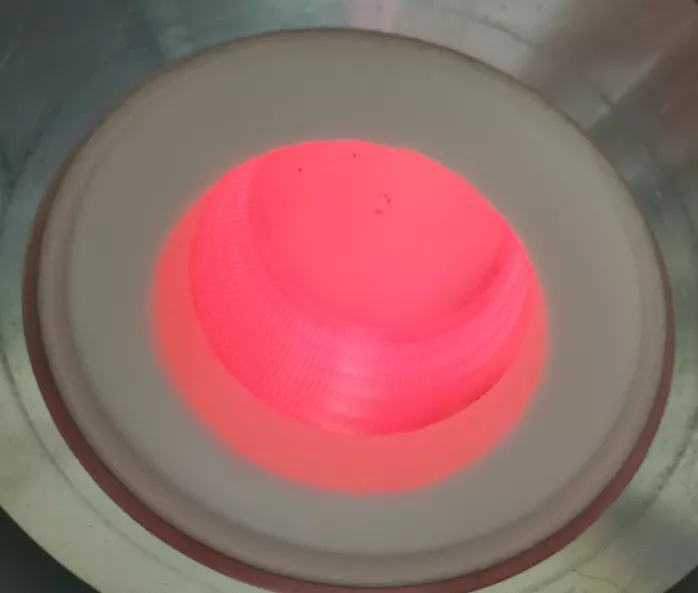

The Dental Vacuum Porcelain Furnace is specifically designed for dental laboratories and manufacturers that require reliable, precise, and efficient porcelain casting. Using a high-quality quartz tube furnace chamber and resistance wire heating elements ensures excellent temperature uniformity and consistent results.

Equipped with an intelligent 30-segment programmable control system, 100 built-in programs (expandable to 500), and a 10-inch touchscreen interface, it combines precision, usability, and flexibility. With a low 1.6kW power rating, the system runs on standard circuits, making it suitable for small laboratories, clinics, and industrial-scale production.

The CVSIC Porcelain Kiln meets the diverse requirements of modern dental practices and manufacturers:

Choose CVSIC Porcelain Kilns for precision, energy savings, and global adaptability in dental porcelain casting. Contact us today for quotations, customization details, or to explore wholesale collaboration opportunities.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

Introduction: Temperature and Materials—The Fundamental Principles of Sintering Furnaces The creation of high-quality restorations is significantly influenced by…

Introduction: Choosing the Ideal Sintering Furnace for Your Dental Laboratory As an engineer, I recognize how the appropriate…

In dental labs, furnaces are essential tools for creating restorations, with sintering and porcelain furnaces being the two…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support