Sintering Furnace vs. Porcelain Furnace? Key Differences to Consider Before Making a Choice

In dental labs, furnaces are essential tools for creating restorations, with sintering and porcelain furnaces being the two…

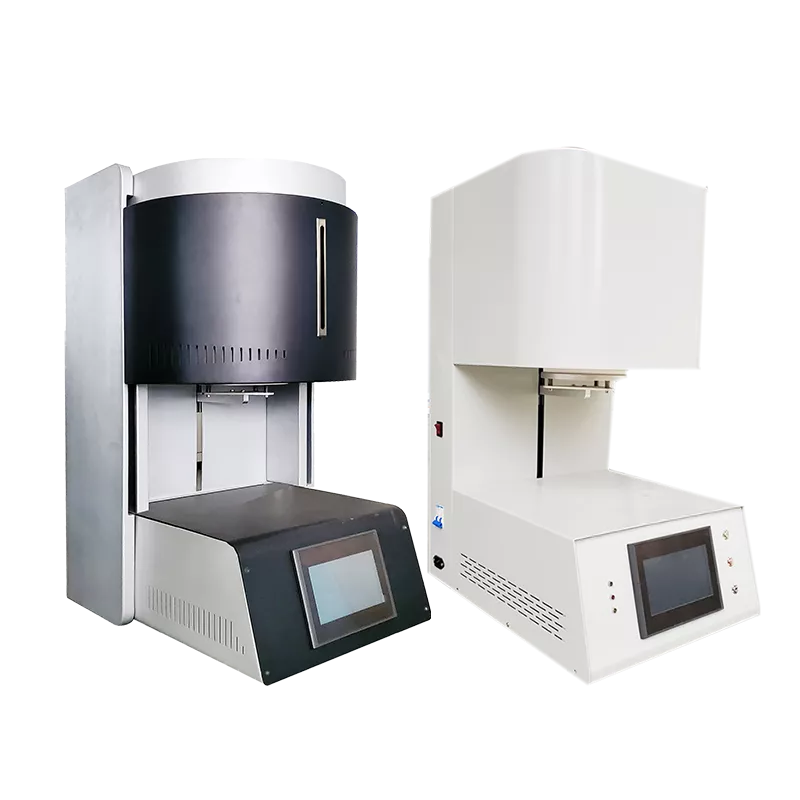

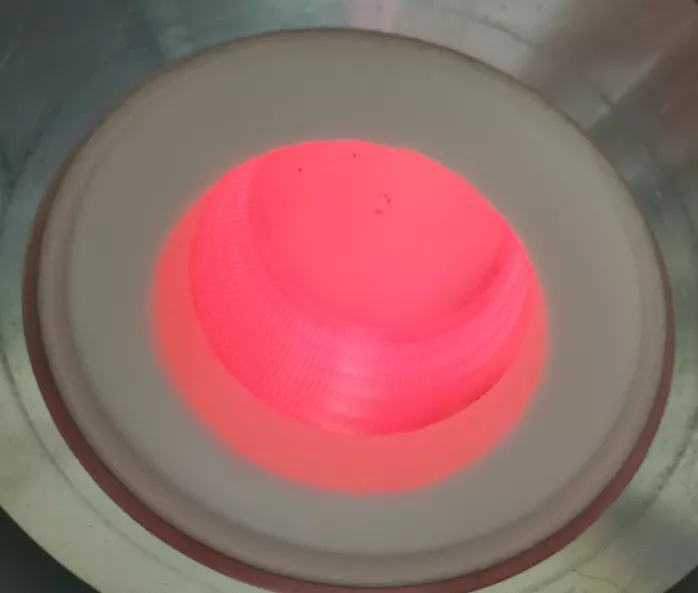

Dental Zirconia Sintering Furnace features an imported pure furnace chamber with precise temperature control, enabling rapid sintering of 80 teeth in 90 minutes and processing up to 150 teeth per cycle. It offers an efficient and environmentally friendly dental sintering solution suitable for dental laboratories and manufacturers worldwide.

CVSIC Dental Zirconia Sintering Furnace is specially designed for dental laboratories and small-scale production environments. With a maximum temperature of 1700℃, compact size, and low power consumption of only 1.5kW, it provides efficient zirconia sintering while operating on standard household circuits.

Built with a high-purity polycrystalline mullite fiber chamber and MoSi₂ heating elements, this furnace offers excellent insulation, a long service life, and precise temperature control with a tolerance of ±1 °C. The integrated 7-inch touchscreen supports 50-segment programmable control and up to 30 stored programs, simplifying operation and improving consistency.

The CVSIC Dental Zirconia Sintering Furnace offers an efficient, precise, and cost-effective solution for dental labs and material research. Contact us today to receive a quote, explore customization options, or learn about wholesale details.

Contact CVSIC today for a one-stop solution for deheating! With over fifteen years of R&D and manufacturing experience, we have absolute confidence in our products! Feel free to contact us for free samples for trial!

In dental labs, furnaces are essential tools for creating restorations, with sintering and porcelain furnaces being the two…

In dental clinics and laboratories, dental furnaces are essential pieces of equipment. Whether producing realistic all-ceramic crowns or…

Introduction: Temperature and Materials—The Fundamental Principles of Sintering Furnaces The creation of high-quality restorations is significantly influenced by…

Introduction: Choosing the Ideal Sintering Furnace for Your Dental Laboratory As an engineer, I recognize how the appropriate…

Contact CVSIC today for exclusive heating solutions. Free samples and technical support!

CE, SGS, ISO Certificate

15+ Years Factory

Operating instructions

7*24 hours after-sales support